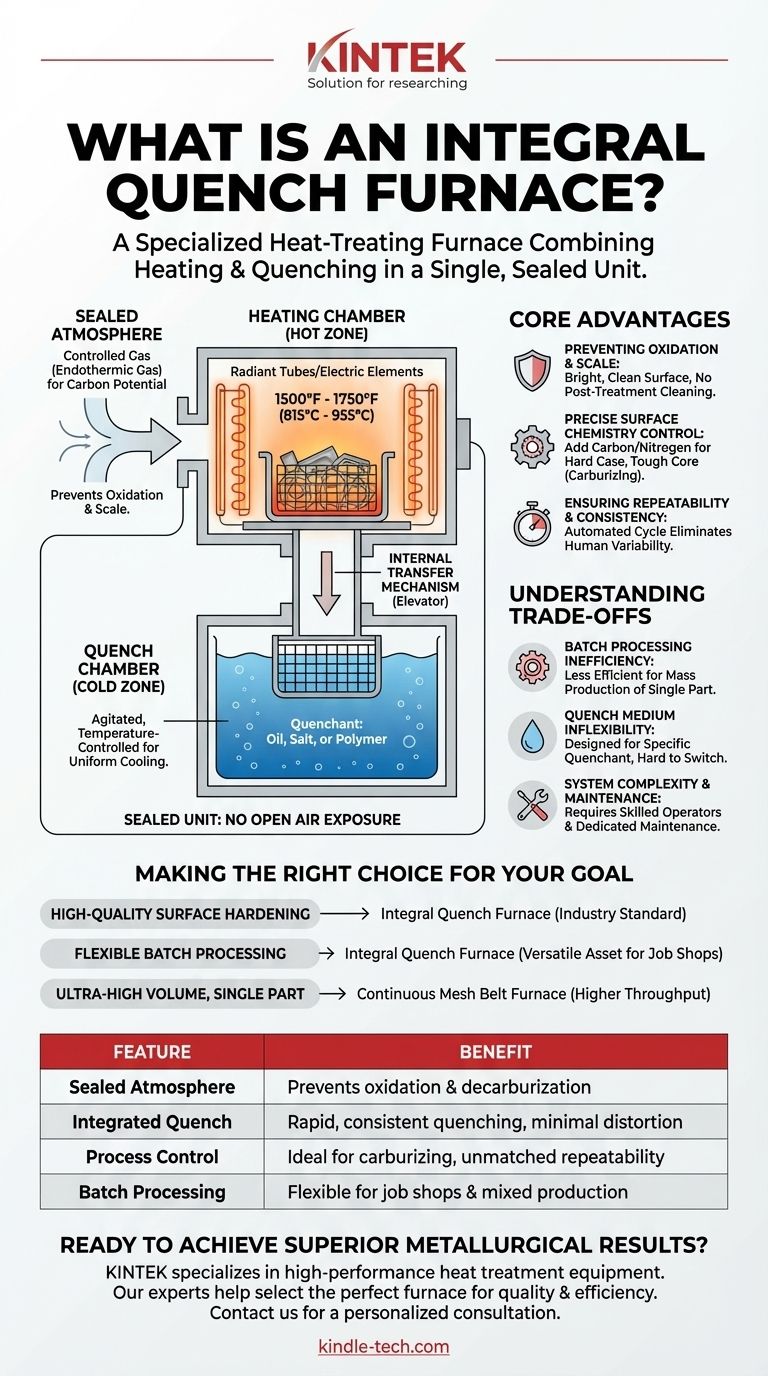

In essence, an integral quench furnace is a specialized type of heat-treating furnace that combines the heating and quenching stages into a single, sealed unit. This design allows for the entire heat treatment process to occur under a tightly controlled atmosphere, preventing the metal parts from being exposed to open air. The result is superior part quality, minimal distortion, and a clean, scale-free surface finish.

An integral quench furnace solves a fundamental problem in heat treatment: how to move a red-hot metal part from a furnace into a quenching liquid without it reacting with air. By integrating both steps into one sealed chamber, it guarantees process control and metallurgical consistency that is difficult to achieve with separate units.

How an Integral Quench Furnace Works

The furnace is composed of distinct sections, but the workpiece never leaves the protective atmosphere as it moves through the process. This seamless internal transfer is the defining feature.

The Sealed Atmosphere

The entire system—including the loading area, heating chamber, and quench tank—is filled with a precisely controlled gas. This is often an endothermic gas, which can be controlled to have a specific carbon potential. This prevents the steel from reacting with oxygen (which causes scale) or losing surface carbon (decarburization).

The Heating Chamber (Hot Zone)

Workpieces are loaded into a basket and moved into the heating chamber. Here, they are heated to a specific austenitizing temperature, typically between 1500°F and 1750°F (815°C to 955°C). The heating is usually done by gas-fired radiant tubes or electric heating elements, which heat the parts without contaminating the protective atmosphere.

The Quench Chamber (Cold Zone)

Directly beneath or adjacent to the heating chamber is the quench chamber. This section contains a large tank of quenching medium, most commonly oil, but sometimes molten salt or polymer. The quenchant is agitated and temperature-controlled to ensure a uniform and predictable cooling rate.

The Internal Transfer Mechanism

Once the parts have "soaked" at temperature for the required time, an internal elevator or chain conveyor automatically lowers the entire workload from the hot zone directly into the quench tank in the cold zone. This transfer happens in seconds, ensuring the steel is quenched at the optimal moment and never exposed to outside air.

The Core Advantage: Unmatched Process Control

The integrated design isn't just for convenience; it provides fundamental metallurgical benefits that are critical for high-performance components.

Preventing Oxidation and Scale

By eliminating exposure to oxygen, the furnace produces parts with a bright, clean surface. This drastically reduces or eliminates the need for costly and time-consuming post-treatment cleaning processes like shot blasting or chemical pickling.

Precise Surface Chemistry Control

For processes like carburizing or carbonitriding, the furnace's atmosphere is actively managed to add a controlled amount of carbon (and nitrogen) to the surface of the part. This creates a hard, wear-resistant "case" on top of a tougher, more ductile core—perfect for gears and bearings.

Ensuring Repeatability and Consistency

Because the entire cycle of heating, soaking, and quenching is automated and contained, it removes human variability and environmental factors. This ensures that every part in a batch, and every batch run, receives the exact same thermal treatment, leading to highly predictable and consistent material properties.

Understanding the Trade-offs

While powerful, the integral quench furnace is not the solution for every application. Understanding its limitations is key to making an informed decision.

Batch Processing Inefficiency at High Volume

Integral quench furnaces operate on a batch-by-batch basis. While this offers great flexibility for processing different parts or running different cycles, it can be less efficient than a continuous furnace for the mass production of a single, identical component.

Quench Medium Inflexibility

The furnace is designed around a specific type of quenchant (e.g., oil). Switching from oil to water or salt is a major, often impractical, overhaul. This limits the ability to easily change quench severity for different materials or part geometries within the same furnace.

System Complexity and Maintenance

These are sophisticated systems involving atmosphere generators, advanced temperature and carbon-potential controllers, and internal mechanical systems. They require skilled operators to run and a dedicated maintenance program to ensure reliability and safety.

Making the Right Choice for Your Goal

To determine if an integral quench furnace is the correct tool, consider your primary manufacturing objective.

- If your primary focus is high-quality surface hardening: The integral quench furnace is the industry standard for creating hard, wear-resistant cases on parts like gears, shafts, and bearings with minimal distortion and no scale.

- If your primary focus is flexible batch processing: The ability to run different cycles (carburizing, neutral hardening, annealing) on various part sizes makes the IQF an extremely versatile asset for job shops or mixed-production environments.

- If your primary focus is ultra-high volume of a single part: A continuous mesh belt furnace, where parts move constantly through heating and quenching zones, may offer a higher throughput and lower cost-per-part.

Understanding the integral quench furnace's design is key to leveraging its power for precise and repeatable metallurgical outcomes.

Summary Table:

| Feature | Benefit |

|---|---|

| Sealed Atmosphere | Prevents oxidation and decarburization for a clean, scale-free finish. |

| Integrated Quench | Ensures rapid, consistent quenching for minimal distortion and predictable hardness. |

| Process Control | Ideal for carburizing and carbonitriding, offering unmatched repeatability. |

| Batch Processing | Provides flexibility for job shops and mixed-production environments. |

Ready to achieve superior metallurgical results with an integral quench furnace?

KINTEK specializes in high-performance lab and heat treatment equipment. Our experts can help you select the perfect furnace to meet your specific needs for quality, consistency, and efficiency.

Contact our team today for a personalized consultation and discover the KINTEK difference in precision heat treating.

Visual Guide

Related Products

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vertical Laboratory Tube Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- What does inerting mean? A Proactive Strategy to Prevent Fires and Explosions

- What are the factors affecting the heat treatment process? Master Temperature, Time, Cooling & Atmosphere

- What is the difference between oxidizing and reducing environments? Key Insights for Chemical Reactions

- Why is a high-precision atmosphere furnace essential for high-nickel cathode sintering? Unlock Battery Performance

- How does a Tube Atmosphere Furnace ensure noble metal activity? Key Steps for Preparing Pt/Al2O3 Catalysts

- What is controlled atmosphere brazing? Achieve Superior, Flux-Free Metal Joining

- What role does an atmosphere sintering furnace play in nickel catalyst SMSI? Optimize Metal-Support Interaction

- What advantages does a high-temperature atmosphere sintering furnace offer for UO2? Precision Fuel Densification