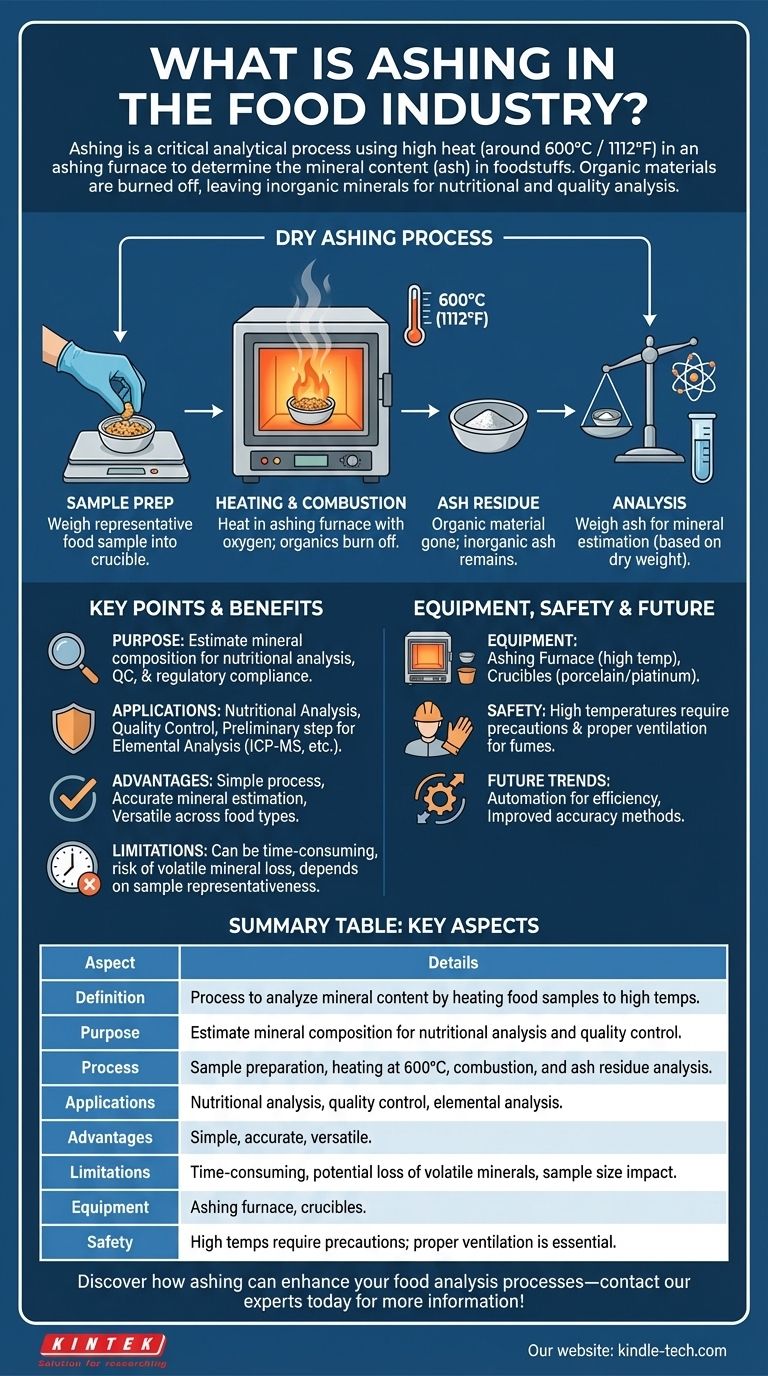

Ashing in the food industry is a critical analytical process used to determine the mineral content in foodstuffs. It involves heating a food sample in an ashing furnace to high temperatures (around 600°C or 1112°F) in the presence of oxygen. This process converts incombustible elements such as minerals into oxides, sulfates, and other compounds, leaving behind a residue of ash. The ash content is then used to estimate the concentration of minerals in the sample based on dry weight. Ashing is often a preliminary step in further elemental analysis, providing valuable insights into the nutritional and compositional profile of food products.

Key Points Explained:

-

Definition of Ashing:

- Ashing is a process used in the food industry to analyze the mineral content in food samples. It involves heating the sample to high temperatures to remove organic material, leaving behind inorganic ash.

-

Purpose of Ashing:

- The primary purpose of ashing is to estimate the mineral composition of foodstuffs. This is crucial for nutritional analysis, quality control, and regulatory compliance in the food industry.

-

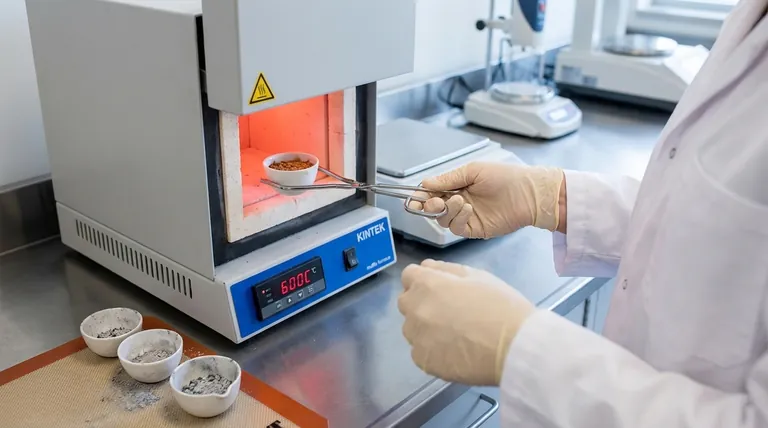

Process of Dry Ashing:

- Sample Preparation: A small, representative portion of the food sample is weighed and placed in a crucible.

- Heating: The sample is heated in an ashing furnace at temperatures around 600°C (1112°F) in the presence of oxygen.

- Combustion: Organic materials in the sample are burned off, leaving behind inorganic minerals in the form of oxides, sulfates, and other compounds.

- Ash Residue: The remaining ash is weighed, and the mineral content is calculated based on the dry weight of the sample.

-

Temperature and Conditions:

- The process typically occurs at temperatures around 600°C (1112°F) to ensure complete combustion of organic materials while preserving the inorganic mineral content.

-

Applications in Food Science:

- Nutritional Analysis: Ashing helps determine the mineral content, which is essential for assessing the nutritional value of food products.

- Quality Control: It ensures that food products meet specific quality standards and regulatory requirements.

- Elemental Analysis: Ashing is often a preliminary step before more detailed elemental analysis, such as atomic absorption spectroscopy or inductively coupled plasma mass spectrometry (ICP-MS).

-

Advantages of Ashing:

- Simplicity: The process is straightforward and does not require complex equipment beyond an ashing furnace.

- Accuracy: It provides a reliable estimate of the mineral content in food samples.

- Versatility: Ashing can be applied to a wide range of food products, from cereals and dairy to meats and vegetables.

-

Limitations of Ashing:

- Time-Consuming: The process can be slow, especially when dealing with large sample sizes.

- Loss of Volatile Minerals: Some minerals may be lost during the heating process, leading to potential inaccuracies.

- Sample Size: The accuracy of the results depends on the representativeness of the sample, which can be challenging with heterogeneous food products.

-

Equipment Used:

- Ashing Furnace: A specialized furnace capable of reaching and maintaining high temperatures is essential for the ashing process.

- Crucibles: Heat-resistant containers made of materials like porcelain or platinum are used to hold the sample during heating.

-

Safety Considerations:

- High Temperatures: Handling samples and equipment at high temperatures requires proper safety precautions to prevent burns or fires.

- Ventilation: Adequate ventilation is necessary to remove any fumes or gases produced during the combustion process.

-

Future Trends:

- Automation: Advances in technology may lead to more automated ashing processes, reducing the time and labor required.

- Improved Accuracy: New methods and equipment may enhance the accuracy of mineral content analysis, reducing the limitations associated with traditional ashing techniques.

In summary, ashing is a fundamental technique in the food industry for analyzing the mineral content of foodstuffs. It provides valuable data for nutritional analysis, quality control, and regulatory compliance. While the process has some limitations, it remains a widely used and reliable method for estimating mineral composition in food samples.

Summary Table:

| Aspect | Details |

|---|---|

| Definition | Process to analyze mineral content by heating food samples to high temps. |

| Purpose | Estimate mineral composition for nutritional analysis and quality control. |

| Process | Sample preparation, heating at 600°C, combustion, and ash residue analysis. |

| Applications | Nutritional analysis, quality control, elemental analysis. |

| Advantages | Simple, accurate, versatile. |

| Limitations | Time-consuming, potential loss of volatile minerals, sample size impact. |

| Equipment | Ashing furnace, crucibles. |

| Safety | High temps require precautions; proper ventilation is essential. |

Discover how ashing can enhance your food analysis processes—contact our experts today for more information!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the construction of a muffle furnace? A Deep Dive into Its Core Systems

- How do you cool a muffle furnace? Safeguard your equipment and samples from thermal shock.

- What are the applications of sintering? Unlock High-Strength, Complex Parts Manufacturing

- Why is a high-temperature box resistance furnace necessary for mixed rare earth niobate synthesis? | KINTEK

- Why is a high-temperature muffle furnace critical for the impregnation method of rare earth catalyst production?

- Why is it called a muffle furnace? The Key to Contamination-Free High-Temperature Heating

- What is the heating element of a muffle furnace? The Engine for High-Temp Precision

- How to cool a muffle furnace? Ensure Safety and Maximize Equipment Lifespan