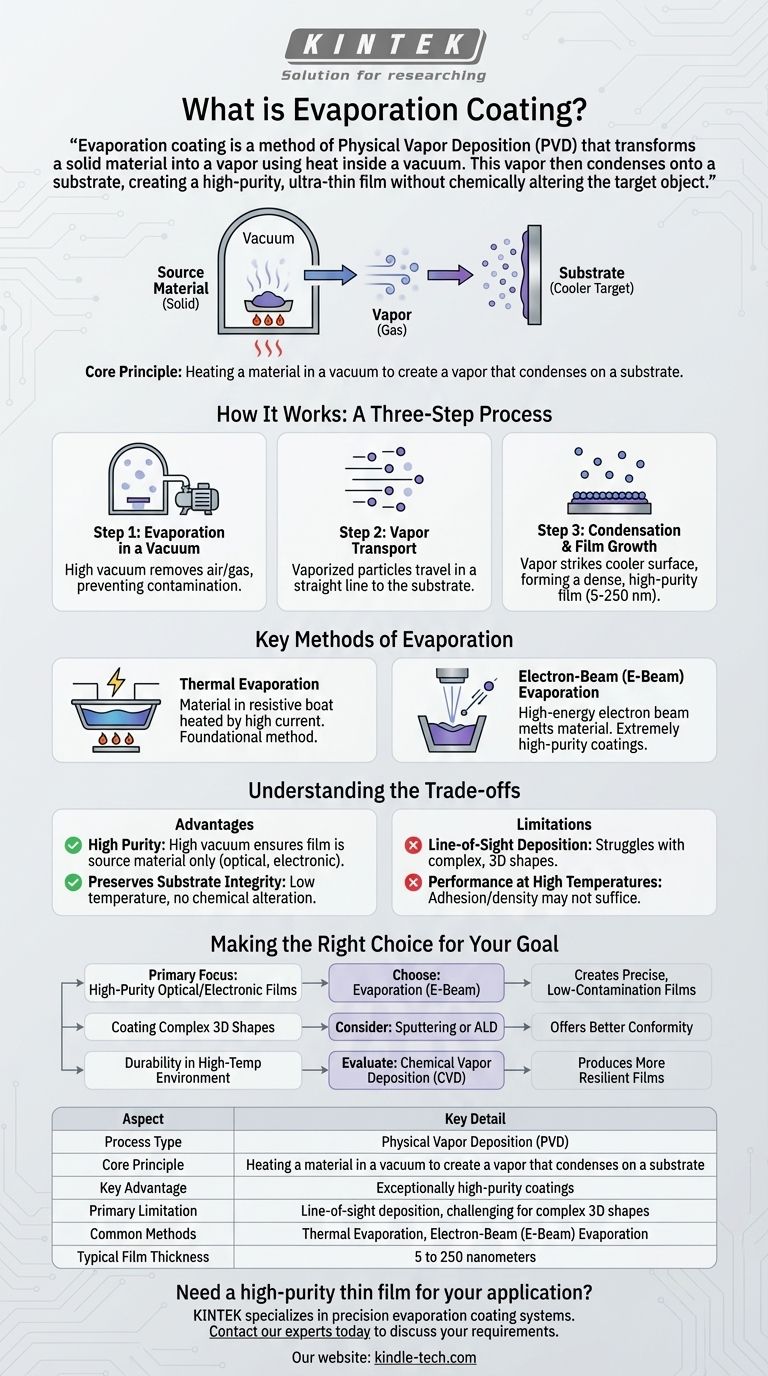

At its core, evaporation coating is a process for depositing an exceptionally thin layer of material onto a surface. It functions by heating a source material inside a high-vacuum chamber until it turns into a vapor. This vapor then travels and condenses onto a cooler target object, known as a substrate, creating a uniform, high-purity film.

Evaporation coating is a method of Physical Vapor Deposition (PVD) that transforms a solid material into a vapor using heat inside a vacuum. This vapor then condenses onto a substrate, creating a high-purity, ultra-thin film without chemically altering the target object.

How Evaporation Coating Works: A Three-Step Process

The entire process is governed by a simple phase transition—solid to gas and back to solid—enabled by precise control over heat and pressure.

Step 1: Evaporation in a Vacuum

The process begins by placing the source material (the material to be coated) into a chamber. A high vacuum is created to remove air and other gas molecules.

This vacuum is critical. It prevents the vaporized coating material from reacting with or being contaminated by other particles and ensures the vapor can travel directly to the substrate.

Step 2: Vapor Transport

Once the chamber is under vacuum, the source material is heated until it evaporates, turning directly into a gas.

Because there are very few other gas atoms to collide with, the vaporized particles travel in a straight line from the source toward the substrate.

Step 3: Condensation and Film Growth

When the hot vapor particles strike the cooler surface of the substrate, they rapidly lose energy and condense back into a solid state.

This condensation builds up atom by atom, forming a dense, thin, and highly pure film on the substrate's surface. Film thickness can be precisely controlled, often ranging from just 5 to 250 nanometers.

Key Methods of Evaporation

While the principle remains the same, the method used to heat the source material defines the specific type of evaporation process.

Thermal Evaporation

This is the foundational method. The source material is placed in a small, electrically resistive container or "boat." A high electrical current is passed through the boat, generating heat that vaporizes the material.

While effective, this method can be less suitable for materials with very high melting points or those that react with the heating element.

Electron-Beam (E-Beam) Evaporation

In this more advanced technique, a high-energy beam of electrons is focused on the source material, which is held in a water-cooled copper hearth or crucible.

The intense, localized energy from the electron beam can melt and evaporate even materials with very high melting points. This process is known for producing extremely high-purity coatings because only the source material is heated, minimizing contamination from surrounding hardware.

Understanding the Trade-offs

No single coating technology is perfect for every application. Understanding the trade-offs of evaporation is key to making an informed decision.

Advantage: High Purity

The high-vacuum environment is the defining strength of evaporation. By removing atmospheric gases, it ensures that the deposited film is composed almost entirely of the source material, which is critical for optical and electronic applications.

Advantage: Preserves Substrate Integrity

Evaporation is a physical process, not a chemical one. The deposition can occur at relatively low substrate temperatures, and it does not alter the dimensional accuracy or underlying properties of the object being coated.

Limitation: Line-of-Sight Deposition

Because the vapor travels in a straight line, evaporation is a "line-of-sight" process. It excels at coating flat surfaces but struggles to uniformly coat complex, three-dimensional shapes with hidden surfaces or deep trenches.

Limitation: Performance at High Temperatures

The adhesion and density of evaporated films may not be sufficient for components that will operate in extremely high-temperature environments. For such applications, other methods like Chemical Vapor Deposition (CVD) may be more suitable.

Making the Right Choice for Your Goal

Selecting the correct deposition method depends entirely on your application's requirements for purity, geometry, and operational stress.

- If your primary focus is creating high-purity optical or electronic films: Evaporation, especially the e-beam method, is an excellent choice for its precision and low contamination levels.

- If your primary focus is coating complex 3D shapes uniformly: You may need to consider alternative methods like sputtering or atomic layer deposition (ALD), which offer better conformity.

- If your primary focus is durability in a high-temperature service environment: You should evaluate other deposition methods like Chemical Vapor Deposition (CVD), which can produce more resilient films.

By understanding its principles and limitations, you can effectively leverage evaporation to achieve the precise, high-quality thin films your project demands.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Principle | Heating a material in a vacuum to create a vapor that condenses on a substrate |

| Key Advantage | Exceptionally high-purity coatings |

| Primary Limitation | Line-of-sight deposition, challenging for complex 3D shapes |

| Common Methods | Thermal Evaporation, Electron-Beam (E-Beam) Evaporation |

| Typical Film Thickness | 5 to 250 nanometers |

Need a high-purity thin film for your optical or electronic application?

KINTEK specializes in precision lab equipment, including evaporation coating systems. Our solutions help you achieve the ultra-thin, contaminant-free films critical for advanced research and manufacturing.

Contact our experts today to discuss how our evaporation coating technology can meet your specific project requirements and enhance your laboratory's capabilities.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance