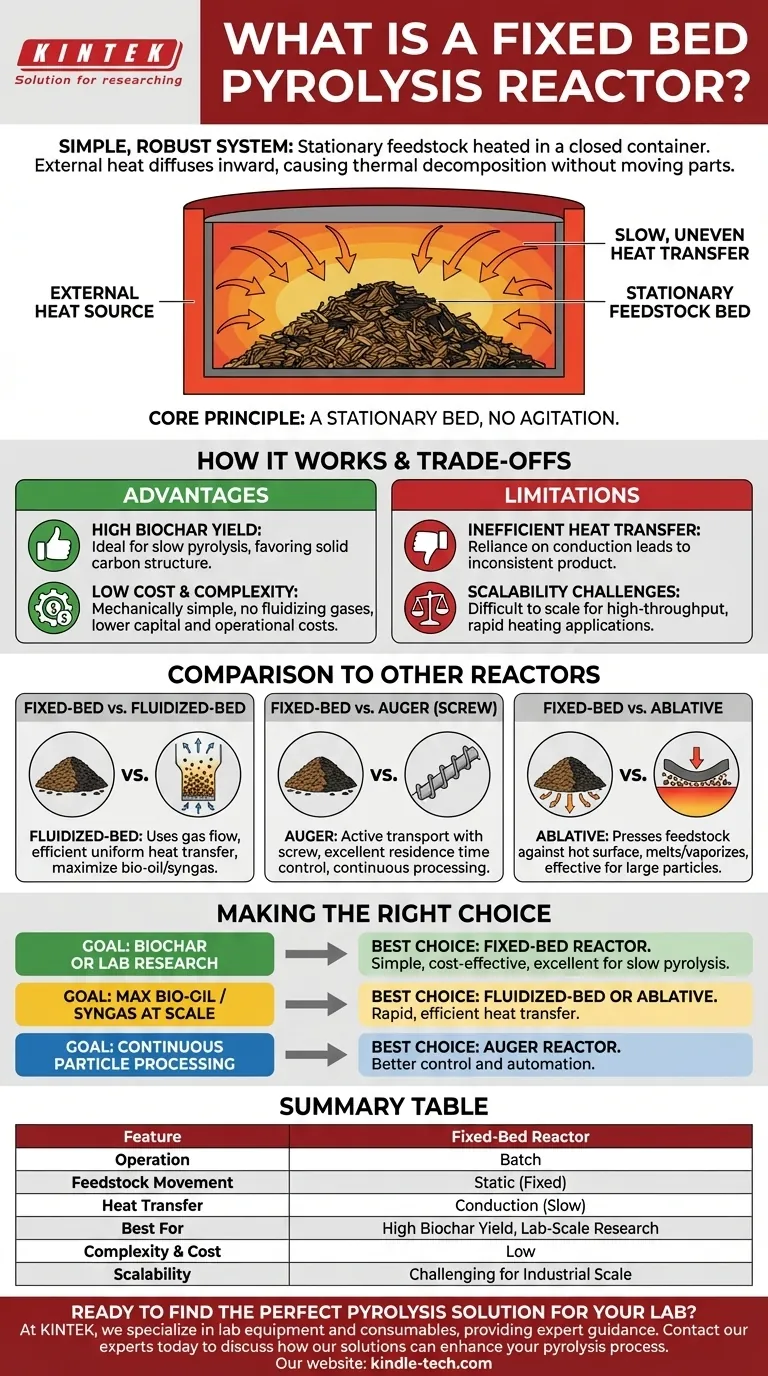

In essence, a fixed-bed pyrolysis reactor is a simple and robust system where a stationary mass of feedstock, or substrate, is heated in a closed container. Heat is applied to the outside of the vessel and slowly diffuses inward, causing the material to thermally decompose without the need for complex moving parts or fluidizing gases.

The defining characteristic of a fixed-bed reactor is its operational simplicity and static design. This makes it highly effective for producing solid biochar through slow pyrolysis but less efficient for generating liquid bio-oils at an industrial scale due to limitations in heat transfer.

How the Fixed-Bed Reactor Works

A fixed-bed reactor is one of the most straightforward designs for pyrolysis, operating on a clear and direct principle.

The Core Principle: A Stationary Bed

The feedstock is loaded into the reactor, where it remains as a static, or "fixed," bed of material.

Unlike more dynamic systems, the particles are not agitated, circulated, or moved by mechanical means during the process.

The Heat Transfer Mechanism

Heat is supplied externally to the reactor walls. This thermal energy must then conduct and radiate from the hot walls through the packed bed of material.

This process is relatively slow and can lead to uneven temperature distribution, as particles closer to the walls get hotter faster than those in the center.

Inherent Simplicity

The design does not require a fluidizing agent like nitrogen gas or bed materials like sand. It also avoids complex internal mechanisms like rotating drums or augers.

This simplicity makes it easier and cheaper to construct and operate, particularly for smaller-scale or laboratory applications.

How Fixed-Bed Compares to Other Reactor Types

Understanding the fixed-bed reactor requires seeing it in context with other common pyrolysis technologies. Each design is optimized for different feedstocks, scales, and desired end products.

Fixed-Bed vs. Fluidized-Bed

A fluidized-bed reactor uses a flow of hot gas to suspend and agitate the feedstock particles, causing them to behave like a fluid.

This creates extremely efficient and uniform heat transfer, making it ideal for rapid pyrolysis to maximize the yield of bio-oil and syngas. The fixed-bed's static nature is comparatively slow.

Fixed-Bed vs. Auger (Screw) Reactor

An auger reactor uses a large, heated screw to actively transport the feedstock through a sealed chamber.

This provides excellent control over residence time and allows for continuous processing, whereas fixed-bed reactors are often operated in batches.

Fixed-Bed vs. Ablative Reactor

An ablative reactor works by pressing feedstock against a rapidly moving hot surface. The material effectively melts and vaporizes on contact.

This method is highly effective for large particles that would heat too slowly in a fixed-bed system, as it bypasses the need for heat to diffuse through the particle itself.

The Trade-offs of the Fixed-Bed Design

The simplicity of the fixed-bed reactor is both its greatest strength and its primary source of limitations.

Key Advantage: High Biochar Yield

The slow heating rates and longer residence times inherent to the fixed-bed design are ideal for slow pyrolysis.

This process favors the formation of a solid carbon structure, resulting in a higher yield of biochar compared to other reactor types.

Key Advantage: Low Cost and Complexity

With no major moving parts or requirements for fluidizing gases, these reactors are mechanically simple. This reduces both the initial capital cost and ongoing operational complexity.

Primary Limitation: Inefficient Heat Transfer

The reliance on conduction through a static bed is the reactor's main weakness. This can result in an inconsistent product and makes it difficult to process large volumes of material efficiently.

Primary Limitation: Scalability Challenges

The poor heat transfer characteristics make it very difficult to scale up fixed-bed reactors for high-throughput industrial applications, especially those targeting liquid fuels where rapid heating is critical.

Making the Right Choice for Your Goal

Selecting the correct reactor technology depends entirely on your primary objective, feedstock, and desired scale of operation.

- If your primary focus is producing biochar or conducting lab-scale research: The fixed-bed reactor is an excellent, cost-effective choice due to its simplicity and effectiveness in slow pyrolysis.

- If your primary focus is maximizing bio-oil or syngas yield at scale: A fluidized-bed or ablative reactor is far superior due to its rapid and efficient heat transfer capabilities.

- If your primary focus is continuous processing of particulate matter: An auger reactor offers better control and automation for moving material through the system consistently.

Ultimately, choosing the right reactor is about matching the technology's inherent strengths to your specific production goals.

Summary Table:

| Feature | Fixed-Bed Reactor |

|---|---|

| Operation | Batch |

| Feedstock Movement | Static (Fixed) |

| Heat Transfer | Conduction (Slow) |

| Best For | High Biochar Yield, Lab-Scale Research |

| Complexity & Cost | Low |

| Scalability | Challenging for Industrial Scale |

Ready to find the perfect pyrolysis solution for your lab?

At KINTEK, we specialize in lab equipment and consumables, providing expert guidance to help you select the right reactor technology for your specific research or production goals—whether you're focused on biochar, bio-oil, or syngas.

Contact our experts today to discuss how our solutions can enhance your pyrolysis process and drive your projects forward.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds