In essence, a heating and drying oven is a specialized piece of laboratory or industrial equipment designed for precise thermal processing. Its core purpose is to heat materials in a highly controlled and uniform environment. This allows for applications such as drying glassware, sterilizing equipment, hardening coatings, or removing moisture from samples.

The primary role of a heating and drying oven is not simply to generate heat, but to create a highly controlled and uniform thermal environment. This precision is essential for removing moisture, sterilizing equipment, or curing materials without causing damage or inconsistent results.

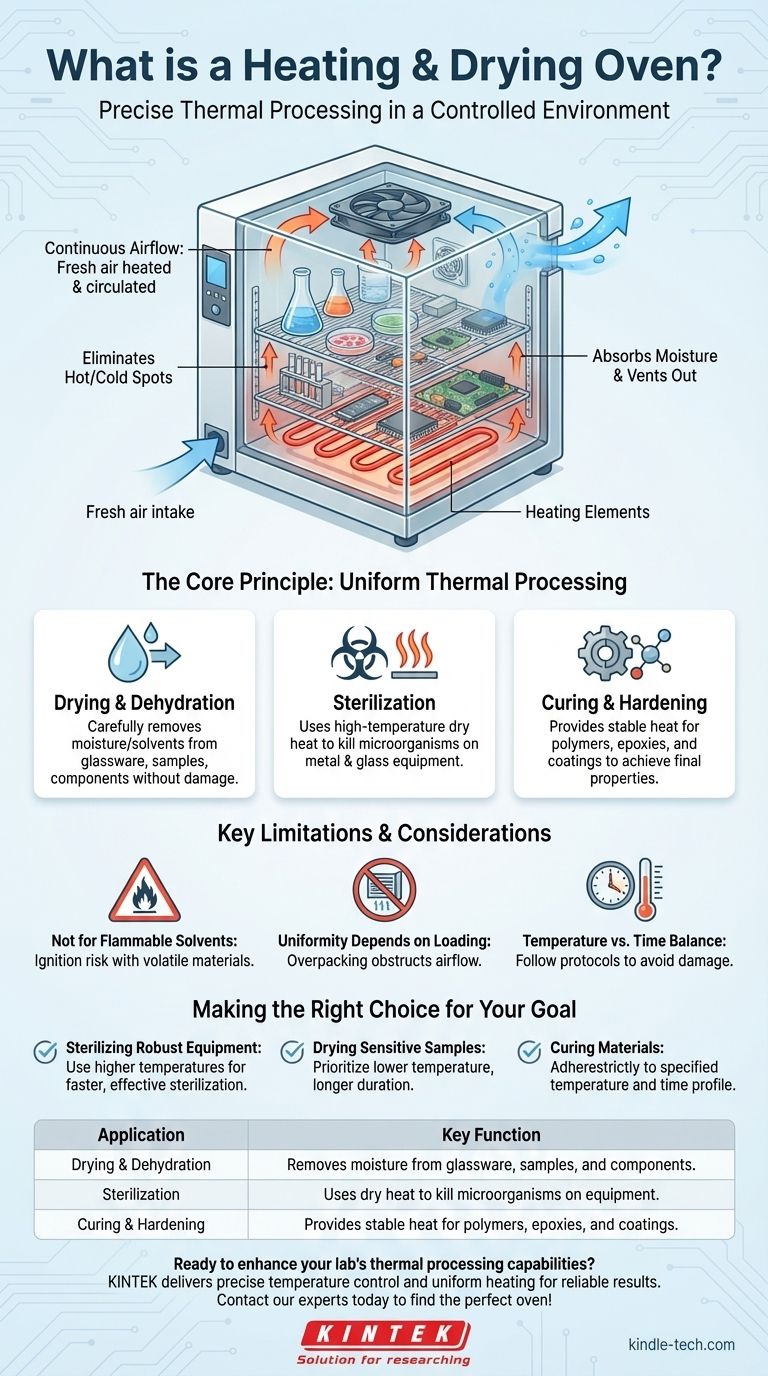

The Core Principle: Uniform Thermal Processing

The key feature that distinguishes a drying oven from a simple heater is its ability to maintain a consistent temperature throughout its entire chamber. This uniformity is critical for repeatable and reliable results.

How It Achieves Uniformity

A drying oven works by drawing in fresh air and passing it over internal heating elements. This heated air is then actively circulated or dissipated throughout the chamber. This process eliminates "hot spots" and "cold spots," ensuring every item inside is exposed to the same temperature conditions.

The Role of Air Circulation

The continuous airflow is what makes it a drying oven. As the hot, dry air circulates, it absorbs moisture from the surfaces of the items inside. This now-moist air is then vented out of the oven, allowing a continuous cycle of fresh, dry air to enter and repeat the process until the material is fully dried.

Key Applications in Professional Settings

The precise control offered by these ovens makes them indispensable for several key tasks.

Drying and Dehydration

This is the most common application. It is used to carefully remove water or other solvents from laboratory glassware, chemical samples, or electronic components without causing damage.

Sterilization

Dry heat is an effective method for sterilizing metal and heat-proof glass equipment. By maintaining a high temperature for a specific duration, the oven can kill microorganisms, making tools safe for reuse in sensitive biological or chemical work.

Curing and Hardening

Many industrial materials, such as polymers, epoxies, and specialized coatings, require a specific temperature cycle to "cure" or harden properly. Drying ovens provide the stable thermal environment needed to achieve the material's desired final properties.

Understanding the Limitations

While highly effective, it's important to understand the operational context and limitations of a standard drying oven.

Not for Flammable Solvents

A standard heating and drying oven is not designed to handle flammable or volatile materials. The combination of heat, contained vapors, and electrical components presents a significant ignition risk. Specialized explosion-proof ovens are required for such tasks.

Uniformity Depends on Loading

The oven's ability to circulate air evenly depends on how it is loaded. Overpacking the chamber or blocking air vents can obstruct airflow, leading to uneven heating and defeating the oven's primary purpose.

Temperature vs. Time

Achieving the desired outcome is a balance between temperature and time. Using an excessively high temperature to speed up a process can damage sensitive samples or lead to incomplete curing. Following established protocols for your specific material is critical.

Making the Right Choice for Your Goal

Applying this understanding requires matching the oven's capability to your specific objective.

- If your primary focus is sterilizing robust equipment: You can utilize higher temperatures for faster, effective sterilization of glass and metal tools.

- If your primary focus is drying sensitive samples: Prioritize a lower temperature setting over a longer duration to gently remove moisture without compromising the sample's integrity.

- If your primary focus is curing materials: Adhere strictly to the material's specified temperature and time profile to ensure proper hardening and performance.

Ultimately, using a heating and drying oven effectively is about leveraging its precise control to achieve a predictable and repeatable outcome.

Summary Table:

| Application | Key Function |

|---|---|

| Drying & Dehydration | Removes moisture from glassware, samples, and components. |

| Sterilization | Uses dry heat to kill microorganisms on equipment. |

| Curing & Hardening | Provides stable heat for polymers, epoxies, and coatings. |

Ready to enhance your lab's thermal processing capabilities? A KINTEK heating and drying oven delivers the precise temperature control and uniform heating you need for reliable drying, sterilization, and curing. Our lab equipment is designed for accuracy and durability, serving the exacting needs of modern laboratories. Contact our experts today to find the perfect oven for your application!

Visual Guide

Related Products

- 1200℃ Muffle Furnace Oven for Laboratory

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Automatic Laboratory Heat Press Machine

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- Is high ash content good? A Guide to Understanding Pet Food Mineral Levels

- In which industry is the muffle furnace used? Discover Its Role in Science and Industry

- What role does a laboratory muffle furnace play in ruthenium oxide thin film decomposition? Enhance Film Crystallinity

- What role does a high-temperature box furnace play in the production of iron-substituted manganese oxide powders?

- Why is a high-temperature muffle furnace necessary for NiO nanoparticle calcination? Master Precise Phase Control

- Why is a secondary heat treatment in a calcination furnace required? Unlock Active Catalyst Performance

- What is the working principle of a muffle furnace? Achieve Precise, Contamination-Free Heating

- What role does a high-temperature muffle furnace play in the measurement of ash content in biomass samples? Accurate Analysis Guide