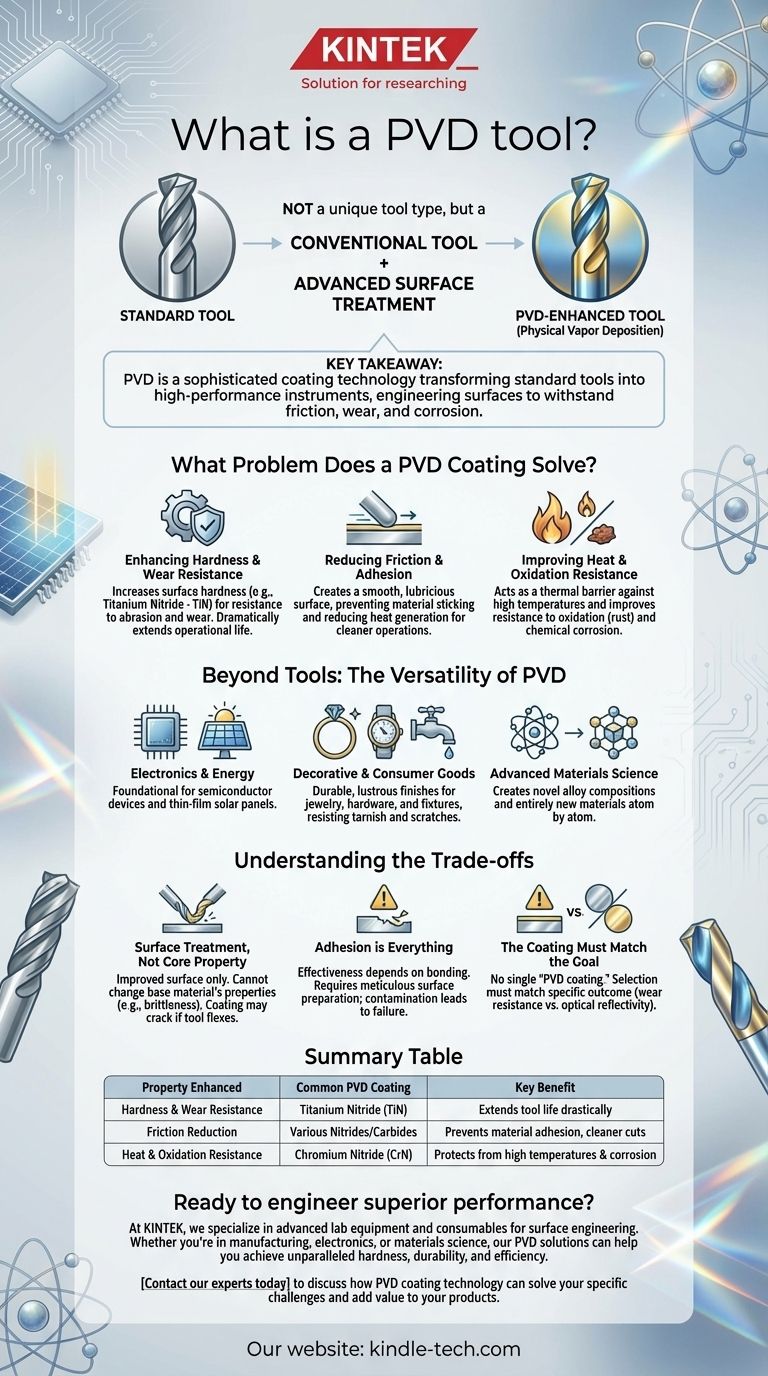

At its core, a "PVD tool" is not a unique type of tool, but rather a conventional tool that has been enhanced with an advanced surface treatment. Physical Vapor Deposition (PVD) is a process that applies a very thin, durable film onto a tool's surface. This coating dramatically improves the tool's performance by increasing its hardness, wear resistance, and ability to withstand high temperatures.

The key takeaway is that PVD is not the tool itself, but a sophisticated coating technology that transforms a standard tool into a high-performance instrument. It allows us to engineer the surface of an object to solve problems like friction, wear, and corrosion that the base material cannot handle on its own.

What Problem Does a PVD Coating Solve?

PVD is used when the surface of a tool needs properties that the underlying material lacks. The process is a highly effective way to add significant value and performance to an existing component.

Enhancing Hardness and Wear Resistance

The most common application for tools is to increase surface hardness. A coating like Titanium Nitride (TiN) makes a standard steel cutting tool significantly more resistant to abrasion and wear, dramatically extending its operational life.

Reducing Friction and Adhesion

In applications like metal cutting or plastic injection molding, friction creates heat and can cause the workpiece material to stick to the tool. A PVD coating creates an exceptionally smooth and lubricious surface, reducing friction and preventing material adhesion for cleaner operations.

Improving Heat and Oxidation Resistance

PVD coatings act as a thermal barrier, protecting the tool from the high temperatures generated during intensive use. This also improves the tool's resistance to oxidation (rust) and chemical corrosion.

Beyond Tools: The Versatility of PVD

While "PVD tools" are a common term in manufacturing, the technology's applications are incredibly broad, highlighting its versatility in manipulating surface properties.

In Electronics and Energy

PVD is a foundational process in manufacturing semiconductor devices and thin-film solar panels. It is used to deposit the precise, microscopic layers of material required for these electronic and optical functions.

For Decorative and Consumer Goods

The ability to create a thin, durable, and lustrous metallic finish makes PVD ideal for decorative products. It is widely used on jewelry, kitchen and bathroom hardware, and architectural fixtures to provide a finish that is both beautiful and highly resistant to tarnishing and scratches.

In Advanced Materials Science

PVD can be used to create entirely new materials. By co-depositing different elements atom by atom, it's possible to produce novel alloy compositions, such as Titanium-Magnesium, that cannot be made through traditional casting methods.

Understanding the Trade-offs

While powerful, PVD is a specific solution with its own considerations. Understanding these limitations is key to using it effectively.

It's a Surface Treatment, Not a Core Property

A PVD coating improves the surface, but it cannot change the properties of the base material. If the underlying tool is brittle or flexes too much under load, the hard PVD coating can crack or delaminate. The tool and coating must work together as a system.

Adhesion is Everything

The effectiveness of a PVD coating is entirely dependent on how well it bonds to the substrate. This requires meticulous surface preparation before the coating process. Any contamination on the surface will result in poor adhesion and potential flaking.

The Coating Must Match the Goal

There is no single "PVD coating." Different materials are deposited to achieve different outcomes. A coating designed for wear resistance on a cutting tool is very different from one designed for optical reflectivity on glass, requiring careful selection for the specific application.

Making the Right Choice for Your Goal

Applying PVD is a decision based on the specific performance you need to achieve.

- If your primary focus is extending the life of cutting tools or molds: A PVD coating like TiN is an industry-standard solution for drastically improving wear resistance and reducing friction.

- If your primary focus is a durable, aesthetic finish for consumer products: PVD offers a superior alternative to traditional plating for items like hardware, watches, and jewelry.

- If your primary focus is creating thin films for electronic or optical functions: PVD is a fundamental manufacturing technology for semiconductors, solar cells, and specialty glass.

Ultimately, PVD technology allows us to engineer the surface of an object to give it capabilities far beyond what its base material allows.

Summary Table:

| Property Enhanced | Common PVD Coating | Key Benefit |

|---|---|---|

| Hardness & Wear Resistance | Titanium Nitride (TiN) | Extends tool life drastically |

| Friction Reduction | Various Nitrides/Carbides | Prevents material adhesion, cleaner cuts |

| Heat & Oxidation Resistance | Chromium Nitride (CrN) | Protects tools from high temperatures & corrosion |

Ready to engineer superior performance into your tools and components?

At KINTEK, we specialize in advanced lab equipment and consumables for surface engineering. Whether you're in manufacturing, electronics, or materials science, our PVD solutions can help you achieve unparalleled hardness, durability, and efficiency.

Contact our experts today to discuss how PVD coating technology can solve your specific challenges and add value to your products.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition