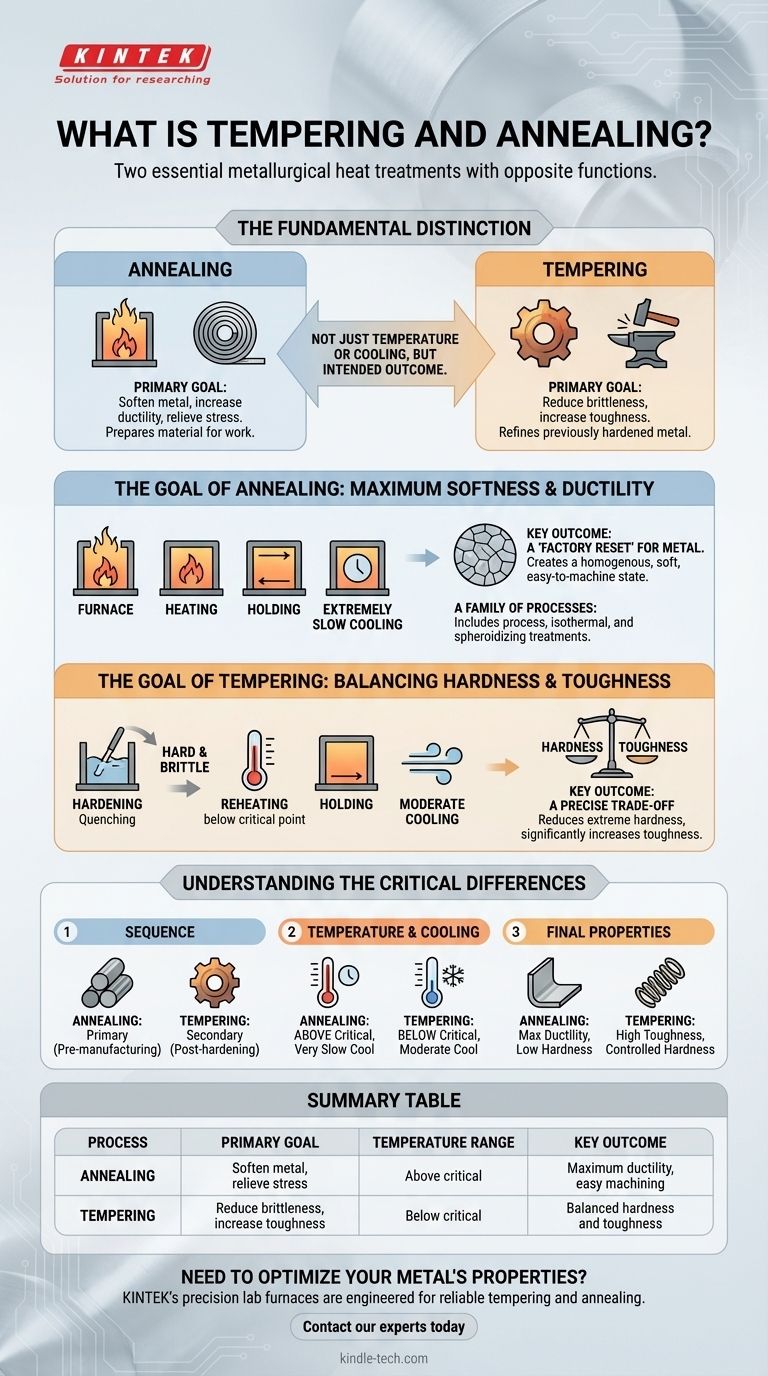

In the world of metallurgy, tempering and annealing are both essential heat treatment processes, but they serve opposite functions and are applied at different stages. Annealing is a process used to soften metal, increase its ductility, and relieve internal stresses, making it easier to work with. Tempering, in contrast, is a secondary process performed after a hardening treatment to reduce the resulting brittleness and increase the metal's overall toughness.

The fundamental distinction is not merely the temperature or cooling speed, but the intended outcome. Annealing aims to reset the metal to its softest, most workable state. Tempering is used to precisely fine-tune a previously hardened metal, trading some hardness for crucial toughness.

The Goal of Annealing: Maximum Softness and Ductility

Annealing is a preparatory process designed to put a metal into its most stable and workable condition. It's often performed on materials that will undergo significant plastic deformation, like stamping, deep drawing, or complex machining.

The Process Explained

The annealing process involves three main stages: heating, holding, and cooling. The metal is heated to a specific temperature above its critical transformation point (known as the Ac1 or Ac3 temperature).

It is then "soaked" or held at this temperature for a sufficient time to allow the material's internal microstructure to fully transform into a more uniform and stable state.

The most critical step is the extremely slow cooling, which is often achieved by leaving the part inside the furnace as it cools down. This slow rate allows for the formation of a coarse, stress-free grain structure, which is responsible for the resulting softness and ductility.

Key Outcome: A "Reset" Button for Metal

Think of annealing as a "factory reset" for the metal's microstructure. It undoes the effects of previous work-hardening or heat treatments, relieving internal stresses that could otherwise lead to cracking or distortion during manufacturing.

The final product is a metal that is homogenous, soft, and easy to machine or form.

A Family of Processes

While "full annealing" (heating above the upper critical temperature) is the most common understanding, the term encompasses a range of specific treatments.

These include process annealing, isothermal annealing, and spheroidizing, each tailored to achieve slightly different microstructures for specific applications.

The Goal of Tempering: Balancing Hardness and Toughness

Tempering is never a standalone process. It is always performed after a hardening procedure, such as quenching, which leaves the metal extremely hard but also very brittle and unsuitable for most applications.

The Process Explained

Tempering involves reheating the already hardened part to a temperature well below its critical transformation point. The exact temperature is carefully controlled, as it directly dictates the final properties of the component.

After being held at the tempering temperature, the part is cooled, typically in still air. This cooling rate is much faster than in annealing but slow enough to prevent the formation of the brittle structures that quenching creates.

Key Outcome: A Precise Trade-off

Tempering is fundamentally a compromise. It reduces the extreme hardness and internal stress created by quenching, which in turn significantly increases the material's toughness—its ability to absorb energy and resist fracturing.

The higher the tempering temperature, the more hardness is sacrificed in exchange for greater toughness. This allows engineers to dial in the perfect balance for an application, from the hard, sharp edge of a blade to the durable, flexible nature of a spring.

Understanding the Critical Differences

While both processes involve heating and cooling, their opposition in purpose, temperature, and sequence defines their use.

Sequence of Operations

Annealing is a primary process used to prepare raw material for manufacturing.

Tempering is a secondary or finishing process performed on a part that has already been shaped and hardened.

Temperature and Cooling Rate

Annealing requires heating the metal above its critical temperature, followed by a very slow cool to achieve maximum softness.

Tempering requires reheating a hardened part to a temperature below its critical point, followed by a moderate cool to balance hardness and toughness.

Final Material Properties

Annealing produces a metal with maximum ductility, low hardness, and minimal internal stress.

Tempering produces a material with a controlled combination of high hardness (though less than a fully quenched state) and significantly improved toughness.

Making the Right Choice for Your Application

Choosing between these processes is straightforward once you define your goal for the material.

- If your primary focus is preparing a metal for extensive shaping, machining, or cold working: Annealing is the correct choice to maximize ductility and relieve internal stresses.

- If your primary focus is refining a hardened part that is too brittle for its intended use: Tempering is the necessary step to increase its toughness and prevent it from fracturing in service.

- If your primary focus is completely removing the effects of prior work and returning a metal to its softest state: Full annealing is the definitive process to reset the material's microstructure.

Ultimately, selecting the right process depends entirely on whether your goal is to prepare metal for work or to perfect the properties of a finished part.

Summary Table:

| Process | Primary Goal | Temperature Range | Key Outcome |

|---|---|---|---|

| Annealing | Soften metal, relieve stress | Above critical temperature | Maximum ductility, easy machining |

| Tempering | Reduce brittleness, increase toughness | Below critical temperature | Balanced hardness and toughness |

Need to optimize your metal's properties? KINTEK's precision lab furnaces are engineered for reliable tempering and annealing processes. Whether you're preparing materials for fabrication or enhancing the toughness of finished components, our equipment delivers the consistent temperature control and uniform heating your laboratory requires. Contact our experts today to discuss the right heat treatment solution for your specific application!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- How does tempering reduce hardness? Achieve the Perfect Balance of Toughness and Durability

- What are the safety precautions for using a muffle furnace? Essential Tips for Safe Operation

- What is the highest temperature of a furnace? Unlocking the Limits of Extreme Heat

- What causes increase in ash content? Uncover the hidden culprits that harm your equipment.

- How do you keep a sample in a muffle furnace? A Guide to Safe and Accurate Placement