In the aerospace industry, heat treatment is a non-negotiable manufacturing process used to deliberately alter the physical and mechanical properties of a metal. It involves precisely controlled heating and cooling to change a material's internal microstructure. This is done to achieve specific, mission-critical characteristics like superior strength, fatigue resistance, and durability, which are fundamental to the safety and performance of every aircraft.

The core purpose of heat treatment in aerospace is not simply to make parts harder. It is a highly engineered metallurgical tool used to unlock the maximum potential of an alloy, tailoring its properties to withstand the immense stresses, extreme temperatures, and cyclical loads experienced during flight.

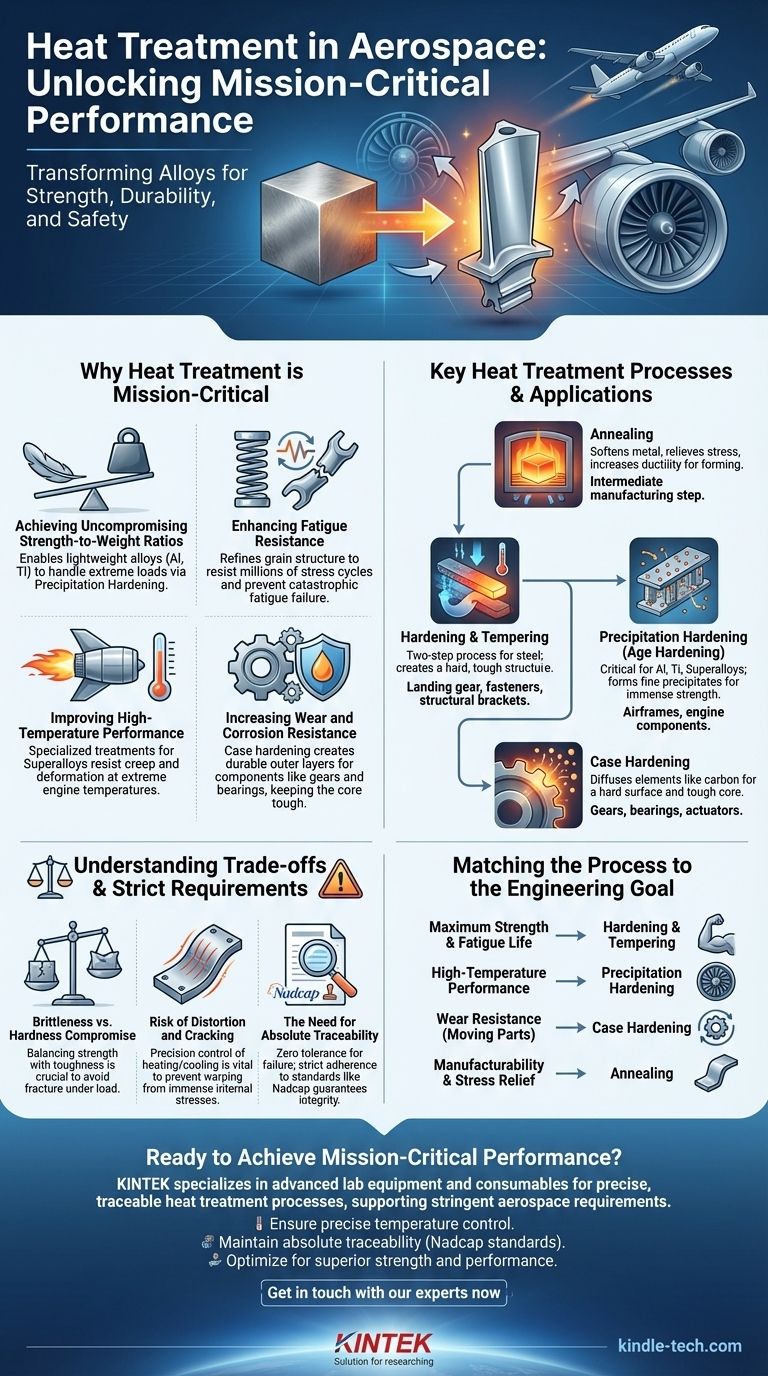

Why Heat Treatment is Mission-Critical

Heat treatment transforms a standard metal alloy into a high-performance aerospace-grade material. Without it, components would be heavier, weaker, and prone to premature failure.

Achieving Uncompromising Strength-to-Weight Ratios

Aerospace engineering is a constant battle against weight. Heat treatment allows for the use of lightweight alloys, such as aluminum and titanium.

These processes, particularly precipitation hardening, dramatically increase the strength of these alloys, enabling them to handle extreme loads without adding unnecessary mass.

Enhancing Fatigue Resistance

Components like wings, landing gear, and fuselages are subjected to millions of stress cycles during their service life. This cyclical loading can lead to metal fatigue and catastrophic failure.

Heat treatment refines the grain structure of the metal and can introduce beneficial compressive stresses, which significantly improve a component's ability to resist the initiation and growth of fatigue cracks.

Improving High-Temperature Performance

Aircraft engines operate at temperatures that would weaken or melt most standard metals. Parts like turbine blades and engine discs must maintain their strength under these conditions.

Specialized heat treatments for superalloys (nickel or cobalt-based) create a stable microstructure that resists "creep"—the tendency of a material to slowly deform over time at high temperatures.

Increasing Wear and Corrosion Resistance

Many aerospace components, such as gears, bearings, and actuators, require extremely hard surfaces to resist wear, while the core must remain tough to absorb shock.

Case hardening processes achieve this by diffusing elements like carbon or nitrogen into the surface of the part, creating a durable outer layer without making the entire component brittle.

Key Heat Treatment Processes and Their Applications

Different engineering goals require different heat treatment methods. The choice of process is dictated by the alloy and the component's specific function.

Annealing

Annealing is a process that heats a metal and allows it to cool slowly. This softens the metal, relieves internal stresses from manufacturing, and increases its ductility.

It is often used as an intermediate step to make a component easier to machine or form before it undergoes its final hardening treatment.

Hardening and Tempering

This is a two-step process primarily for steel alloys. First, hardening involves heating the steel and then rapidly cooling it (quenching) to create a very hard but brittle structure.

Second, tempering involves reheating the part to a lower temperature to reduce that brittleness, increase toughness, and achieve the desired balance of mechanical properties for parts like fasteners and structural brackets.

Precipitation Hardening (Age Hardening)

This is the most critical process for high-strength aluminum, titanium, and nickel-based superalloys.

The process involves heating the material to dissolve alloying elements, quenching it, and then holding it at a lower temperature (aging). This causes extremely fine particles, or precipitates, to form within the metal's structure, which act as obstacles to deformation and dramatically increase its strength and hardness. This is used extensively on airframes and engine components.

Understanding the Trade-offs and Strict Requirements

Heat treatment is a science of precision, and any deviation can have severe consequences. The process is governed by strict industry standards and inherent metallurgical trade-offs.

The Brittleness vs. Hardness Compromise

A fundamental principle of metallurgy is that as you increase a material's hardness, you typically decrease its toughness and increase its brittleness.

The goal of a process like tempering is to find the optimal balance for a specific application, ensuring a part is strong enough to resist deformation but tough enough to avoid fracturing under sudden loads.

The Risk of Distortion and Cracking

The rapid temperature changes involved in heat treatment, especially quenching, create immense internal stresses.

These stresses can cause thin or complex parts to warp, distort, or even crack if the process is not controlled with extreme precision. The design of the part and the control of heating and cooling rates are critical to preventing this.

The Need for Absolute Traceability

The aerospace industry operates with zero tolerance for material failure. Every heat-treated part must have a fully traceable record of its processing.

Standards like Nadcap (National Aerospace and Defense Contractors Accreditation Program) ensure that facilities adhere to the strictest process controls, from furnace calibration to temperature logging, guaranteeing the integrity of every component.

Matching the Process to the Engineering Goal

The choice of heat treatment is driven entirely by the component's role and the environment it operates in.

- If your primary focus is maximum strength and fatigue life (e.g., landing gear): Hardening and tempering processes are engineered to achieve a tough, high-strength core capable of absorbing immense impact and cyclical loads.

- If your primary focus is high-temperature performance (e.g., turbine blades): Precipitation hardening of superalloys is the essential process to create a stable microstructure that resists material creep.

- If your primary focus is wear resistance for moving parts (e.g., gears): Case hardening techniques like carburizing or nitriding are the optimal choice to create a hard surface over a ductile core.

- If your primary focus is manufacturability and stress relief: Annealing is the critical preparatory or final step to make materials workable and ensure dimensional stability.

Ultimately, mastering heat treatment is fundamental to transforming raw metal into a component capable of withstanding the extraordinary demands of flight.

Summary Table:

| Process | Key Goal | Common Aerospace Applications |

|---|---|---|

| Precipitation Hardening | Maximize strength-to-weight ratio | Airframes, engine components (titanium, aluminum alloys) |

| Hardening & Tempering | Balance strength and toughness | Landing gear, fasteners, structural brackets (steel alloys) |

| Case Hardening | Enhance surface wear resistance | Gears, bearings, actuators |

| Annealing | Relieve stress, improve ductility | Intermediate manufacturing step for formability |

Ready to achieve mission-critical performance for your aerospace components?

At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary for precise, traceable heat treatment processes. Whether you are developing high-strength airframes, durable landing gear, or heat-resistant turbine blades, our solutions support the stringent requirements of aerospace manufacturing.

We help you:

- Ensure precise temperature control for processes like precipitation hardening.

- Maintain absolute traceability to meet Nadcap and other industry standards.

- Optimize your heat treatment for superior strength, fatigue resistance, and high-temperature performance.

Contact us today to discuss how KINTEK can support your laboratory's critical role in aerospace innovation.

Get in touch with our experts now

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why do you vacuum for heat treatment? Achieve Flawless, High-Performance Metal Components

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost