In materials science, the primary application of the quenching effect is to control the microstructure of a material to achieve specific mechanical properties. This process involves rapidly cooling a workpiece, most commonly steel, from a high temperature to lock in a hard, wear-resistant state. The choice of cooling medium—such as air, oil, water, or brine—is critical, as it directly influences the final characteristics of the material.

The quenching effect is a controlled, rapid cooling process used to lock in a desirable but unstable microstructure. In steel, this means cooling faster than a "critical cooling rate" to form hard martensite instead of softer phases, fundamentally trading ductility for extreme hardness.

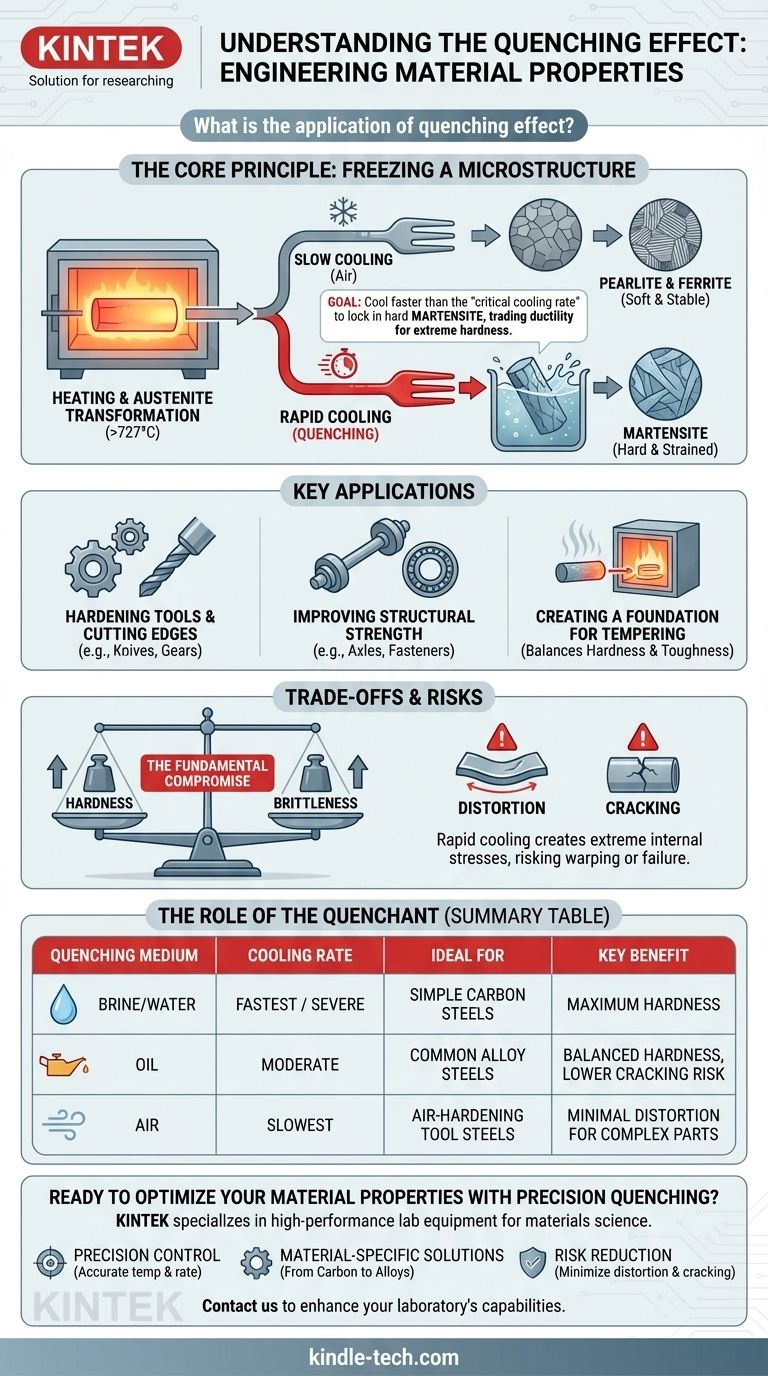

The Core Principle: Freezing a Microstructure in Place

The goal of quenching isn't just to cool a part down. It's to cool it down so quickly that the material's internal atomic structure doesn't have time to rearrange into its softest, most stable state.

The Austenite Transformation

When steel is heated above a critical temperature (typically over 727°C or 1340°F), its crystal structure transforms into a state called austenite. Austenite is a uniform, malleable structure that can dissolve carbon. What happens next, during cooling, determines the steel's final properties.

The Critical Cooling Rate

If austenitic steel is cooled slowly, the carbon atoms have time to move and rearrange, forming softer, more stable structures like pearlite and ferrite. However, if the steel is cooled faster than its critical cooling rate, this natural transformation is suppressed.

Martensite: The Source of Hardness

By cooling rapidly, the austenite is forced into a new, highly strained, and metastable structure called martensite. The carbon atoms are trapped within the iron crystal lattice, creating immense internal stress. This stressed, distorted structure is what makes quenched steel exceptionally hard and brittle.

Key Applications of Quenching

Quenching is not an end in itself but a crucial step in a larger heat treatment process designed to create high-performance components.

Hardening Tools and Cutting Edges

The most common application is to create hardness and wear resistance. Components like knives, drill bits, gears, and chisels are quenched to ensure they can hold a sharp edge and withstand abrasion during use.

Improving Structural Strength

Quenching is also used to increase the yield strength and fatigue resistance of structural parts. Axles, bearings, and fasteners are often quenched to handle high loads and cyclical stress without failing.

Creating a Foundation for Tempering

A part that has only been quenched is too brittle for most practical uses. Therefore, quenching is almost always followed by tempering—a process of reheating the part to a lower temperature to relieve some internal stress. This reduces brittleness and restores a controlled amount of toughness, albeit at the cost of some hardness.

Understanding the Trade-offs and Risks

Applying the quenching effect successfully requires balancing competing factors and managing significant risks.

The Hardness vs. Brittleness Compromise

The fundamental trade-off of quenching is hardness for brittleness. A faster quench results in a higher percentage of martensite, creating a harder but more fragile part. This is why the subsequent tempering process is so critical.

The Risk of Distortion and Cracking

Rapid cooling creates extreme temperature gradients within the material. The outside of the part cools and contracts much faster than the inside, generating massive internal stresses. If these stresses exceed the material's strength, the part can warp, distort, or crack, rendering it useless.

The Role of the Quenchant

The choice of cooling medium (the quenchant) is the primary way to control the cooling rate and manage the risk of cracking.

- Brine and Water: These provide the fastest and most severe quench. They are effective for simple carbon steels but carry the highest risk of distortion and cracking, especially in complex shapes.

- Oil: Cooling in oil is significantly slower and less severe than in water. This makes it the preferred choice for many alloy steels, as it provides a good balance of hardness while dramatically reducing the risk of cracking.

- Air: This is the slowest quench method. It is only effective for specialized "air-hardening" tool steels that contain high amounts of alloys, which slow the austenite transformation enough for martensite to form even during slow cooling. It offers the lowest risk of distortion.

Making the Right Choice for Your Goal

The correct quenching strategy depends entirely on the type of steel and the desired outcome for the component.

- If your primary focus is maximum hardness for simple carbon steels: A rapid water or brine quench is often necessary, but you must be prepared for a high risk of cracking and the absolute need for immediate tempering.

- If your primary focus is balanced hardness for common alloy steels: An oil quench provides a more controlled cooling rate, effectively hardening the part while significantly reducing the risk of distortion.

- If your primary focus is minimal distortion for complex or high-alloy parts: An air quench is the safest method, but it is only effective for specific air-hardening tool steels designed for this process.

Ultimately, mastering the quenching effect is about strategically trading ductility for hardness to precisely engineer the final performance of the material.

Summary Table:

| Quenching Medium | Cooling Rate | Ideal For | Key Benefit |

|---|---|---|---|

| Brine/Water | Fastest/Severe | Simple Carbon Steels | Maximum Hardness |

| Oil | Moderate | Common Alloy Steels | Balanced Hardness, Lower Risk of Cracking |

| Air | Slowest | Air-Hardening Tool Steels | Minimal Distortion for Complex Parts |

Ready to Optimize Your Material Properties with Precision Quenching?

KINTEK specializes in providing high-performance lab equipment and consumables tailored for materials science and heat treatment processes. Whether you're developing cutting tools, structural components, or advanced alloys, our solutions help you achieve the perfect balance of hardness, strength, and durability.

🔬 Our Expertise Supports Your Goals:

- Precision Control: Achieve consistent results with equipment designed for accurate temperature and cooling rate management.

- Material-Specific Solutions: From simple carbon steels to high-alloy tool steels, we provide the right tools for your specific quenching needs.

- Risk Reduction: Minimize distortion and cracking with recommended quenchants and processes.

📞 Contact us today via our contact form to discuss how KINTEK can enhance your laboratory's capabilities and help you master the quenching effect for superior material performance.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout