The best material for a sieve is determined entirely by its intended application. While stainless steel is the most versatile and widely used option for its durability and resistance to corrosion, materials like brass or synthetic polymers are superior in specific scenarios involving cost constraints or the need to prevent metallic contamination.

The central challenge isn't finding a single "best" material, but matching the material's properties—such as chemical resistance, durability, and purity—to the specific requirements of the substance you are sieving and your analytical goals.

The Critical Factors Driving Your Decision

Before comparing materials, you must first define the problem you are solving. Your choice hinges on four key considerations that directly impact the accuracy, longevity, and safety of your work.

The Nature of Your Sample

The primary driver of your decision is the physical and chemical nature of the material you need to analyze.

Is the material highly abrasive, like minerals or aggregates? This demands a hard, wear-resistant material. Is it corrosive, acidic, or alkaline? This requires a chemically inert material to prevent degradation of the sieve.

Required Purity and Contamination Risk

For applications in pharmaceuticals, food science, or high-purity chemistry, preventing sample contamination is non-negotiable.

The sieve material itself must not react with, leach into, or otherwise alter your sample. A brass sieve, for example, could introduce copper or zinc ions, rendering a sensitive chemical analysis useless.

The Sieving Environment

Consider the conditions under which the sieve will be used. Will you be performing wet sieving, requiring constant exposure to liquids?

Will the process involve high temperatures that could damage less robust materials? The environment dictates the necessary level of corrosion resistance and thermal stability.

Durability and Wear Resistance

A sieve is a precision instrument. Its openings must remain consistent to produce repeatable results.

If the mesh or frame warps, stretches, or abrades easily, the sieve's accuracy is compromised. The expected frequency of use and the mechanical stress involved will determine the required durability.

A Comparative Analysis of Common Sieve Materials

With a clear understanding of your requirements, you can now evaluate the most common materials and align their properties with your needs.

Stainless Steel: The Versatile Standard

Stainless steel (typically grades 304 or 316) is the default choice for most laboratory and industrial applications. It offers an excellent balance of properties.

It is highly durable, easy to clean, and offers strong resistance to corrosion and chemical attack. Grade 316 stainless steel is particularly resistant to chlorides and acids, making it ideal for pharmaceutical and food-grade applications.

Brass: The Budget-Conscious Workhorse

Composed of copper and zinc, brass sieves are often less expensive than their stainless steel counterparts. They offer good rigidity and performance with many non-corrosive, abrasive materials.

However, brass tarnishes easily and is susceptible to corrosion from acidic or alkaline substances. Its use is not recommended for food, pharmaceutical, or sensitive chemical applications due to the risk of metallic contamination.

Bronze: The Abrasion-Resistant Alternative

Bronze, an alloy of copper and tin, is tougher and more resistant to corrosion than brass. It stands up well to saltwater and is very durable against abrasive materials.

Like brass, it presents a contamination risk and is generally reserved for applications like geology or materials testing where this is not a concern.

Synthetic Polymers: For Ultimate Purity

Sieves made with nylon or polyester mesh are essential when any form of metallic contamination must be avoided. They are lightweight and resistant to a wide range of chemicals.

Their primary drawback is lower mechanical durability. They are less resistant to abrasion and can be damaged by high temperatures or certain organic solvents. They are also prone to building up static electricity, which can affect the accuracy of sieving very fine powders.

Understanding the Trade-offs

Selecting a sieve material is an exercise in balancing competing priorities. Being aware of these trade-offs is crucial for making an informed decision.

Cost vs. Total Cost of Ownership

A brass sieve may have a lower initial purchase price, but if it corrodes or wears out quickly in your application, it will need frequent replacement.

A more expensive stainless steel sieve often provides a lower total cost of ownership due to its significantly longer service life and greater versatility.

Purity vs. Mechanical Durability

Synthetic mesh provides the highest level of purity by eliminating metal contact, but it cannot withstand the mechanical stress of highly abrasive materials.

You must decide which is more critical for your results: absolute prevention of metallic contamination or the long-term durability needed for aggressive samples.

Frame and Mesh Composition

Pay close attention to whether the frame and mesh are made of the same material. It is common to find a brass frame fitted with a stainless steel mesh to reduce cost.

While functional, this can lead to issues like galvanic corrosion where the two dissimilar metals meet. For maximum durability and consistency, especially in wet environments, a sieve constructed of a single material is superior.

Making the Right Choice for Your Goal

Ultimately, your specific objective dictates the optimal material. Use these guidelines to make a final decision.

- If your primary focus is general lab work, food processing, or pharmaceuticals: Select an all-stainless steel sieve (Grade 316 for enhanced chemical resistance).

- If your primary focus is sieving abrasive materials on a strict budget: A brass or bronze sieve is a practical choice, provided that slight metallic contamination is acceptable.

- If your primary focus is absolute sample purity with no metal contact: Use a sieve with a synthetic mesh like nylon or polyester, and be mindful of its physical limitations.

- If your primary focus is high-precision particle size analysis: Invest in a certified sieve made entirely of high-grade stainless steel to ensure dimensional stability and repeatability.

By systematically evaluating your sample, environment, and analytical needs, you can select a sieve material that delivers reliable and accurate results for years to come.

Summary Table:

| Material | Best For | Key Advantages | Key Limitations |

|---|---|---|---|

| Stainless Steel | General lab work, pharmaceuticals, food processing | High durability, excellent chemical resistance, easy to clean | Higher initial cost |

| Brass | Budget-conscious abrasive material sieving | Lower cost, good rigidity | Prone to corrosion, metallic contamination risk |

| Bronze | Abrasive materials, saltwater environments | High abrasion resistance, tougher than brass | Metallic contamination risk |

| Synthetic Polymers (Nylon/Polyester) | Absolute sample purity, sensitive chemicals | No metallic contamination, chemical resistant | Lower mechanical durability, static buildup |

Need help selecting the perfect sieve for your lab? The right choice is critical for accurate particle analysis and contamination-free results. KINTEK specializes in high-quality lab sieves and equipment, offering expert guidance to match your specific application—whether you require the durability of stainless steel or the purity of synthetic polymers. Contact our specialists today to ensure your sieving process is precise, reliable, and efficient!

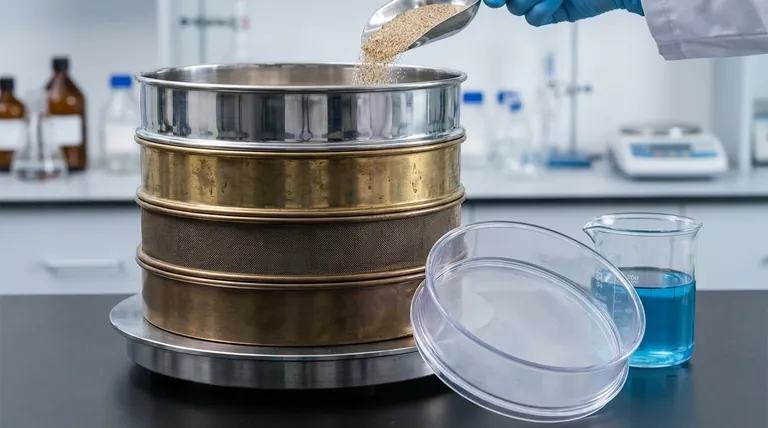

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials

- What is the function of sieving equipment in CuAlMn alloys? Master Pore Size Precision