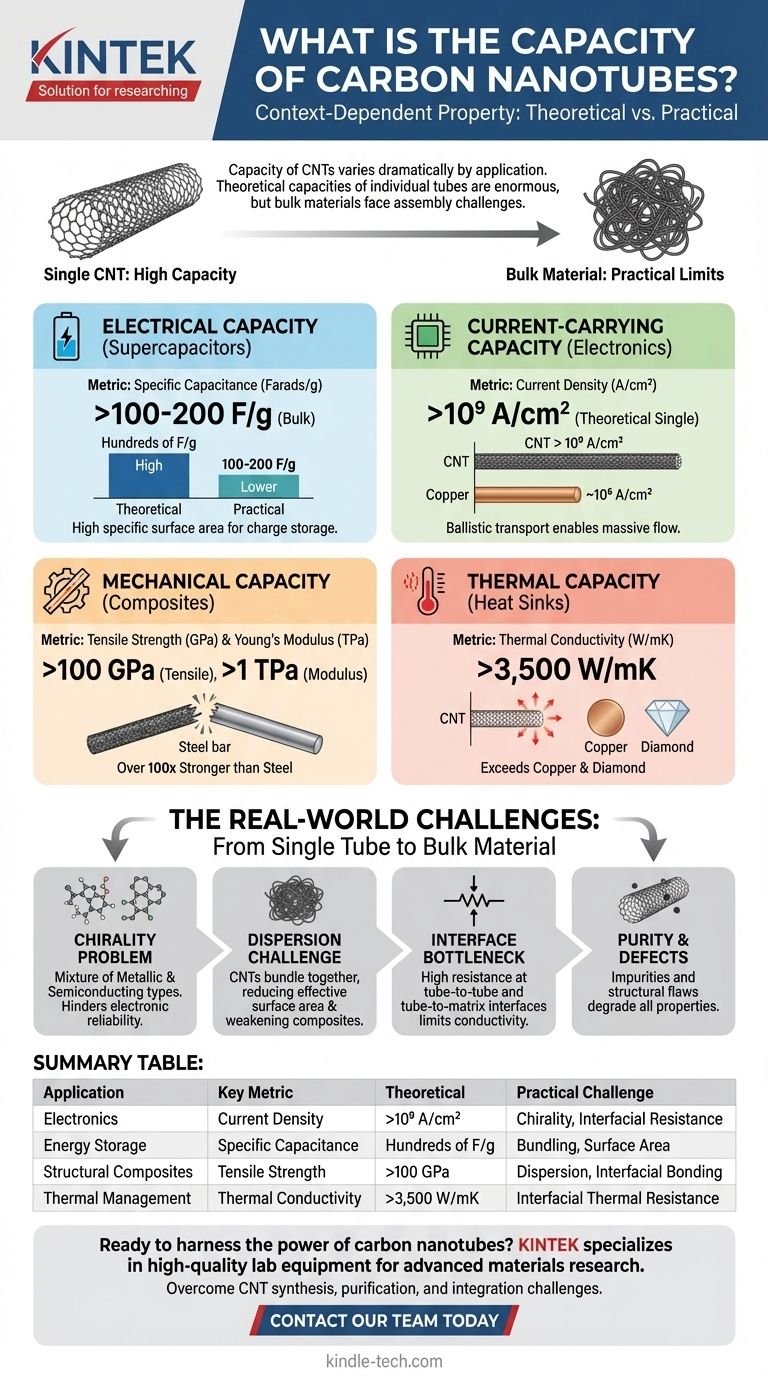

The 'capacity' of a carbon nanotube (CNT) is not a single value but a context-dependent property that varies dramatically based on the application. For electronics, their current-carrying capacity can exceed 10⁹ A/cm², over 1,000 times that of copper. In energy storage, their theoretical specific capacitance for supercapacitors can be hundreds of Farads per gram. For structural materials, their tensile strength can be over 100 times that of steel.

The exceptional theoretical capacities of individual carbon nanotubes are often orders of magnitude greater than what is achievable in bulk, real-world materials. The primary challenge lies not in the intrinsic properties of a single tube, but in controllably synthesizing, purifying, and assembling them into functional devices.

Unpacking "Capacity": Key Metrics by Application

To understand the potential of CNTs, we must analyze "capacity" through the lens of its intended function. The properties that make a CNT ideal for a battery are different from those needed for a structural composite.

Electrical Capacity (For Supercapacitors)

The relevant metric here is specific capacitance, measured in Farads per gram (F/g). It represents the ability to store electrical charge per unit of mass.

CNTs are promising due to their incredibly high specific surface area, which is where charge storage occurs in an electric double-layer capacitor.

Theoretically, the specific capacitance of an individual CNT can be very high, but practical values for materials made from CNT "mats" or "forests" are typically in the range of 100-200 F/g.

Current-Carrying Capacity (For Electronics)

For applications like semiconductor interconnects, the key metric is current density, measured in Amperes per square centimeter (A/cm²).

Single-walled CNTs can exhibit ballistic transport, where electrons flow with virtually no resistance. This allows for a massive current-carrying capacity estimated to be over 10⁹ A/cm².

This is more than three orders of magnitude higher than conventional metals like copper and aluminum, which fail at around 10⁶ A/cm² due to electromigration.

Mechanical Capacity (For Composites)

For structural reinforcement, we look at tensile strength (the force required to pull something apart) and Young's modulus (stiffness).

An individual CNT is one of the strongest materials known. Its theoretical tensile strength can exceed 100 Gigapascals (GPa), and its Young's modulus can be over 1 Terapascal (TPa).

For comparison, high-strength steel has a tensile strength of around 1-2 GPa and a Young's modulus of 0.2 TPa.

Thermal Capacity (For Heat Sinks)

Here, the critical property is thermal conductivity, measured in Watts per meter-Kelvin (W/mK). It defines how well a material conducts heat.

Individual CNTs exhibit exceptionally high thermal conductivity along their axis, with room-temperature values reported to be over 3,500 W/mK.

This rivals or exceeds the thermal conductivity of diamond (~2,200 W/mK) and is far superior to copper (~400 W/mK), making them a target for thermal management applications.

Understanding the Trade-offs: From Single Tube to Bulk Material

The staggering numbers above apply to perfect, individual nanotubes. The primary difficulty is translating these properties into a macroscopic, usable material. This is where the theoretical potential meets real-world engineering challenges.

The Chirality Problem

The atomic arrangement of a CNT, known as its chirality, determines if it behaves like a metal or a semiconductor.

Most synthesis methods produce a mix of both types. For electronic applications, this is a major hurdle, as you cannot build reliable circuits from a random mix of conductors and semiconductors.

The Dispersion Challenge

CNTs have a strong tendency to bundle together due to van der Waals forces, much like strands of wet hair.

These bundles reduce the effective surface area available for chemical reactions or charge storage. In composites, clumps act as defects, weakening the material rather than strengthening it. Achieving uniform dispersion is a critical and difficult processing step.

The Interface Bottleneck

The point where one CNT touches another, or where a CNT touches a surrounding material, is called an interface. These interfaces create resistance.

This interfacial resistance is often the limiting factor for thermal and electrical conductivity in a bulk CNT material. The excellent conductivity of the tube itself is bottlenecked by the poor connection between tubes.

Purity and Defects

Real-world CNT samples contain impurities, such as leftover catalyst particles from synthesis, and structural defects in the nanotube walls.

These imperfections disrupt the perfect lattice of the nanotube, degrading its mechanical, electrical, and thermal properties significantly.

How to Apply This to Your Goal

Choosing to leverage CNTs requires aligning your primary objective with their strongest, most achievable properties in a bulk format.

- If your primary focus is energy storage: Prioritize sourcing CNTs with a high specific surface area and good purity to maximize electrochemical capacitance, but engineer your device for realistic, not theoretical, values.

- If your primary focus is mechanical strength: Focus on achieving excellent dispersion and strong interfacial bonding within your composite matrix, as this is more critical than the strength of an individual tube.

- If your primary focus is advanced electronics: Realize that you are on the cutting edge; success depends on sourcing CNTs with controlled chirality and overcoming significant fabrication challenges at the nanoscale.

- If your primary focus is thermal management: Your main engineering obstacle will be minimizing thermal resistance at the interfaces, both between tubes and between the CNT material and the component you need to cool.

Ultimately, harnessing the power of carbon nanotubes is less about their phenomenal theoretical limits and more about mastering the science of their assembly.

Summary Table:

| Application | Key Metric | Theoretical Capacity (Individual CNT) | Practical Challenge |

|---|---|---|---|

| Electronics | Current Density | > 10⁹ A/cm² | Chirality control, interfacial resistance |

| Energy Storage | Specific Capacitance | Hundreds of F/g | Bundling reduces surface area |

| Structural Composites | Tensile Strength | > 100 GPa | Dispersion, interfacial bonding |

| Thermal Management | Thermal Conductivity | > 3,500 W/mK | Interfacial thermal resistance |

Ready to harness the power of carbon nanotubes for your specific application? KINTEK specializes in providing high-quality lab equipment and consumables tailored to advanced materials research. Whether you're developing next-generation electronics, high-capacity energy storage, or ultra-strong composites, our expertise can help you overcome the challenges of CNT synthesis, purification, and integration. Contact our team today to discuss how we can support your laboratory's innovation goals.

Visual Guide

Related Products

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Large Vertical Graphite Vacuum Graphitization Furnace

- Platinum Auxiliary Electrode for Laboratory Use

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

People Also Ask

- What are the functions of a glassy carbon electrode in CV testing of antioxidants? Enhance Your Redox Analysis Accuracy

- Why is a glassy carbon disc electrode an indispensable consumable? Ensure Reliable Catalyst Evaluation Today

- What actions and conditions are strictly prohibited when working with a glassy carbon sheet? Protect Your Investment and Data Integrity

- What are the fundamental characteristics of glassy carbon? Discover its Unique Synergy of Properties

- What are the typical physical specifications for glassy carbon sheets? Unlock Superior Performance for Your Lab