The cooling stage of heat treatment is the controlled process of reducing a metal's temperature after it has been heated to a specific point. This is often the most critical phase, as the speed and method of cooling—known as the quench—directly determine the material's final mechanical properties, such as its hardness, strength, and ductility. The choice of cooling method can range from a rapid plunge into brine to a slow cooling over hours inside a furnace.

The core principle to understand is that it's not just about making the metal cold. The rate of cooling dictates the final microscopic structure of the material, locking in the desired properties and transforming it for its intended purpose.

Why Cooling Rate Is the Deciding Factor

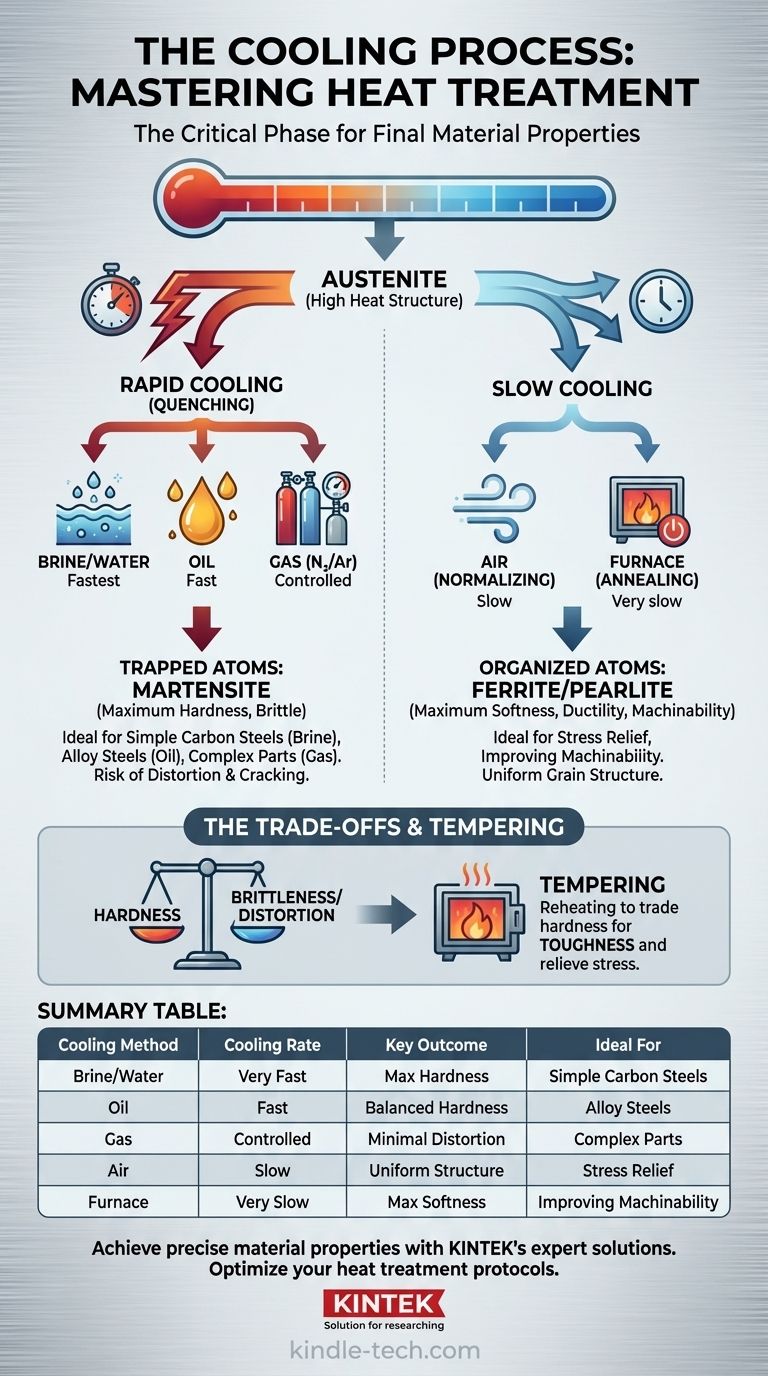

At high heat-treating temperatures, the atomic structure of a metal like steel changes into a form called austenite. The goal of the cooling process is to control how this austenite transforms back into a different structure at room temperature.

The Science of Transformation

When cooled rapidly, the atoms don't have time to rearrange themselves into a soft, stable state. They become trapped in a highly stressed, hard, and brittle structure, such as martensite. This is the primary goal of hardening processes.

When cooled slowly, the atoms have ample time to move into an organized, low-stress crystalline structure. This results in a softer, more ductile, and more machinable material with structures like ferrite and pearlite.

Common Cooling Methods and Their Purpose

The "quenchant," or cooling medium, is chosen based on the desired cooling rate, the type of metal, and the part's geometry. Each medium extracts heat at a different speed.

Quenching: The Path to Maximum Hardness

Quenching refers to any process of rapid cooling. The goal is to cool the metal fast enough to prevent the formation of soft structures.

- Brine or Water Quenching: A saltwater solution provides the fastest cooling rate. It is extremely effective but also the most severe, creating immense internal stresses that can cause thin or complex parts to warp or crack.

- Oil Quenching: Oil cools more slowly than water. This makes it a very common choice for many alloy steels, as it provides a good balance between achieving high hardness and reducing the risk of distortion.

- Gas Quenching: Using gases like nitrogen or argon under high pressure offers a highly controlled and clean cooling process. It's slower than oil but ideal for high-value parts, complex geometries, and advanced materials used in aerospace where minimizing distortion is critical. As a rule, steel uses 99.995% pure nitrogen, while superalloys may require 99.999% nitrogen or argon.

Slow Cooling: Prioritizing Stability and Machinability

Not all heat treatment is for hardening. Sometimes the goal is to soften the metal, relieve stress, or refine its internal grain structure.

- Annealing: This involves cooling the material as slowly as possible, often by leaving it inside the turned-off furnace. It produces the softest, most ductile state, making the metal easy to machine or form.

- Normalizing: This involves removing the part from the furnace and letting it cool in still air. It's faster than annealing but much slower than quenching. Normalizing is often used to create a more uniform grain structure and relieve stress that has built up from prior manufacturing steps like forging or cold-forming.

Understanding the Trade-offs: Hardness vs. Brittleness

Selecting a cooling process is a balancing act. Achieving one property often means sacrificing another.

The Risk of Distortion and Cracking

The faster the cooling rate, the greater the thermal shock and internal stress. While a fast quench produces maximum hardness, it also creates a high risk of the part warping, distorting, or even cracking. The quenchant must be aggressive enough to harden the part but not so aggressive that it destroys it.

The Need for Tempering

A part that has been quenched to its maximum hardness is almost always too brittle for any practical application. It is like glass—hard but easily shattered.

For this reason, quenching is almost always followed by a second heat treatment called tempering. This process involves reheating the hardened part to a much lower temperature to relieve stress and trade a small amount of hardness for a significant increase in toughness.

Selecting the Right Cooling Process

Your choice of cooling method must be aligned with the final properties your component requires.

- If your primary focus is maximum hardness: Use the most aggressive quench your material can tolerate without failing, such as brine for simple carbon steels or a fast oil for alloys.

- If your primary focus is minimizing distortion: Use a slower, more controlled method like vacuum gas quenching or a milder oil, especially for complex or high-precision parts.

- If your primary focus is improving machinability or softness: Use a slow cooling process like furnace cooling (annealing) or air cooling (normalizing).

Ultimately, mastering the cooling process is mastering the final properties of the metal itself.

Summary Table:

| Cooling Method | Cooling Rate | Key Outcome | Ideal For |

|---|---|---|---|

| Brine/Water Quenching | Very Fast | Maximum Hardness (Martensite) | Simple carbon steels |

| Oil Quenching | Fast | Balanced Hardness & Reduced Distortion | Alloy steels |

| Gas Quenching | Controlled | Minimal Distortion, Clean Process | High-value, complex parts (aerospace) |

| Air Cooling (Normalizing) | Slow | Uniform Grain Structure, Stress Relief | Post-forging stress relief |

| Furnace Cooling (Annealing) | Very Slow | Maximum Softness & Ductility | Improving machinability |

Achieve precise material properties in your lab with KINTEK's expert solutions.

Selecting the right cooling method is critical to achieving the exact hardness, strength, and dimensional stability your components require. Whether you are developing high-strength alloys or need to minimize distortion in precision parts, KINTEK provides the advanced lab equipment and consumables to control every step of the heat treatment process.

Our team specializes in helping laboratories like yours optimize quenching and cooling protocols for reproducible, high-quality results. Contact our experts today to discuss how we can support your specific material science and heat treatment challenges.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What role does a vacuum diffusion welding furnace play in the fabrication of multi-layer titanium alloy laminates?

- What is the role of vacuum in deposition? Enabling High-Purity, Controlled Thin-Film Processes

- What is the operating mechanism of a vacuum drying oven in nanomaterials? Preserve Pore Integrity & Prevent Oxidation

- Why is a vacuum drying oven used for LLZ post-treatment? Ensure Superior Substrate Purity and Adhesion

- How does the temperature control of a vacuum distillation furnace affect aluminum-magnesium separation?

- What is the difference between liquid phase sintering and solid phase sintering? Achieve Optimal Material Density

- How does a vacuum brazing furnace work? Achieve Superior, Flux-Free Metal Joining

- What is the advantages of vacuum hardening? Achieve Pristine Surfaces and Unmatched Precision