Determining the cost of a Spark Plasma Sintering (SPS) system is not a matter of looking up a simple price tag. The final investment varies dramatically, spanning the range from high-end laboratory equipment to large-scale industrial machinery, based entirely on the system's specific configuration, capabilities, and scale.

The purchase price of an SPS system is driven by its core technical specifications—primarily size, power, and environmental controls. However, a true cost assessment must also include ongoing operational expenses like power consumption and tooling to understand the total cost of ownership.

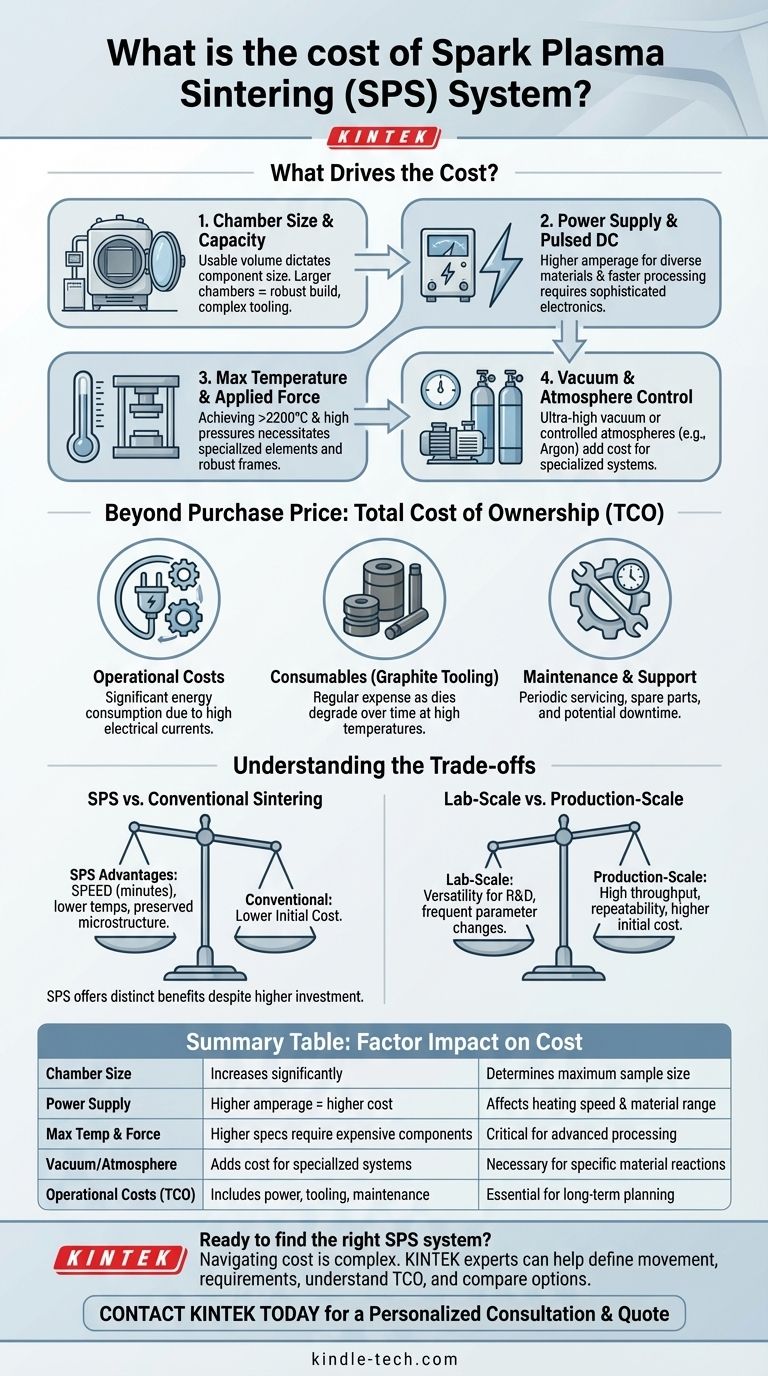

What Drives the Cost of an SPS System?

The final quote for an SPS system is a direct reflection of its engineering complexity and material requirements. Several key factors are responsible for the wide variation in cost.

Factor 1: Chamber Size and Sample Capacity

The usable volume of the vacuum chamber dictates the maximum size of the components you can produce. Larger chambers require more robust construction, larger vacuum pumps, and more complex tooling, all of which significantly increase the initial cost.

Factor 2: Power Supply and Pulsed DC Generator

The heart of an SPS system is its power supply. Systems with higher maximum amperage (e.g., thousands of amps) can process a wider range of materials and larger samples more quickly. This increased power capability requires more sophisticated and expensive electrical components.

Factor 3: Maximum Temperature and Applied Force

Achieving very high temperatures (e.g., above 2200°C) necessitates specialized heating elements, insulation, and chamber materials. Similarly, systems capable of applying higher pressures require more robust frames and hydraulic systems, directly adding to the manufacturing cost.

Factor 4: Vacuum and Atmosphere Control

A basic system includes a standard vacuum pump. However, the cost rises if you require ultra-high vacuum capabilities or the ability to introduce and control specific atmospheres, such as inert gases (Argon) or reactive gases, to influence the sintering process.

Beyond the Purchase Price: Total Cost of Ownership

A sound financial analysis extends beyond the initial capital expenditure. The long-term operational costs are a critical part of the equation.

Operational Costs: Power Consumption

SPS is an energy-intensive process. The high electrical currents used for heating result in significant power consumption, which becomes a major recurring operational expense, especially in a production environment.

Consumables: Graphite Tooling

The dies and punches used to contain the powder sample are typically made of high-purity graphite. These tools degrade over time, especially at high temperatures and pressures, and must be treated as a regular consumable expense.

Maintenance and Support

Like any piece of sophisticated equipment, SPS systems require periodic maintenance by trained technicians. Factoring in the cost of spare parts, service contracts, and potential downtime is essential for a complete financial picture.

Understanding the Trade-offs

Choosing an SPS system involves balancing its unique capabilities against its significant investment cost compared to other technologies.

SPS vs. Conventional Sintering

While a conventional hot press or furnace has a lower initial cost, SPS offers distinct advantages. Its primary benefit is speed, reducing sintering cycles from hours to minutes. This rapid heating also often allows for sintering at lower overall temperatures, which can help preserve fine-grained microstructures and improve final material properties.

Lab-Scale vs. Production-Scale

A smaller laboratory system offers greater versatility for research and development, allowing for frequent changes in parameters and materials. A large production-scale system is optimized for throughput and repeatability of a specific part but comes with a much higher initial investment and less operational flexibility.

Making the Right Choice for Your Goal

To properly evaluate cost, you must first define your primary application for the technology.

- If your primary focus is fundamental materials research: Prioritize a versatile lab-scale system with precise control over atmosphere, temperature, and electrical pulse parameters.

- If your primary focus is process development or pilot production: Seek a mid-size system that balances flexibility with the capacity for larger samples and higher throughput.

- If your primary focus is high-volume industrial production: Concentrate on large-scale, highly automated systems engineered for repeatability, reliability, and minimal operator intervention.

Ultimately, defining your specific material and component requirements is the most critical step in obtaining a meaningful cost for a Spark Plasma Sintering system.

Summary Table:

| Factor | Impact on Cost | Key Considerations |

|---|---|---|

| Chamber Size | Increases significantly with size | Determines maximum sample/part size |

| Power Supply | Higher amperage = higher cost | Affects heating speed and material range |

| Max Temperature & Force | Higher specs require more robust, expensive components | Critical for advanced material processing |

| Vacuum/Atmosphere Control | Adds cost for specialized pumps and gas systems | Necessary for specific material reactions |

| Operational Costs (TCO) | Includes power, graphite tooling, and maintenance | Essential for long-term financial planning |

Ready to find the right SPS system for your lab's budget and research goals?

Navigating the cost and specifications of Spark Plasma Sintering equipment is complex. The experts at KINTEK are here to help. We specialize in providing lab equipment solutions tailored to your specific materials research, process development, or production needs.

We can help you:

- Clarify your technical requirements to match the perfect system.

- Understand the total cost of ownership beyond the initial price.

- Compare lab-scale versus production-scale options for your application.

Contact KINTEK today for a personalized consultation and quote. Let's discuss how an SPS system can accelerate your innovation.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is the purpose of using grinding consumables for surface pretreatment? Enhance Your Vacuum Hot-Pressing Success

- What technical advantages does a Spark Plasma Sintering (SPS) furnace offer? Superior Density for B4C Ceramics

- What role does the pressure system of a vacuum hot pressing furnace play? Optimize Ti-Al Laminated Composite Density

- What is the purpose of a hot pressing system following the reduction of iron powder in a fluidized bed? Stabilize DRI

- How does the vacuum environment impact sintering of diamond-copper composites? Protect Against Thermal Damage

- How does the precise temperature control of a Vacuum Hot Press affect AZ31/UCF/AZ31 composites? Optimize Bonding

- What role does a vacuum hot pressing furnace play in Ti2AlNb/TA15 fabrication? Achieve Seamless Diffusion Bonding

- How does a vacuum hot-press furnace optimize MoSi2 composite microstructure? Master Material Densification & Performance