At its core, the difference between balanced and unbalanced magnetrons lies in the geometry and strength of their magnetic fields. A balanced magnetron has a symmetrical magnetic field designed to confine plasma very close to the sputtering target surface. In contrast, an unbalanced magnetron uses an intentionally asymmetric field, typically with stronger outer magnets, to guide a portion of the plasma away from the target and towards the substrate being coated.

The choice is not about which is "better," but which is right for the task. Balanced magnetrons prioritize efficient erosion of the sputtering target, while unbalanced magnetrons prioritize modifying the properties of the growing film through controlled ion bombardment.

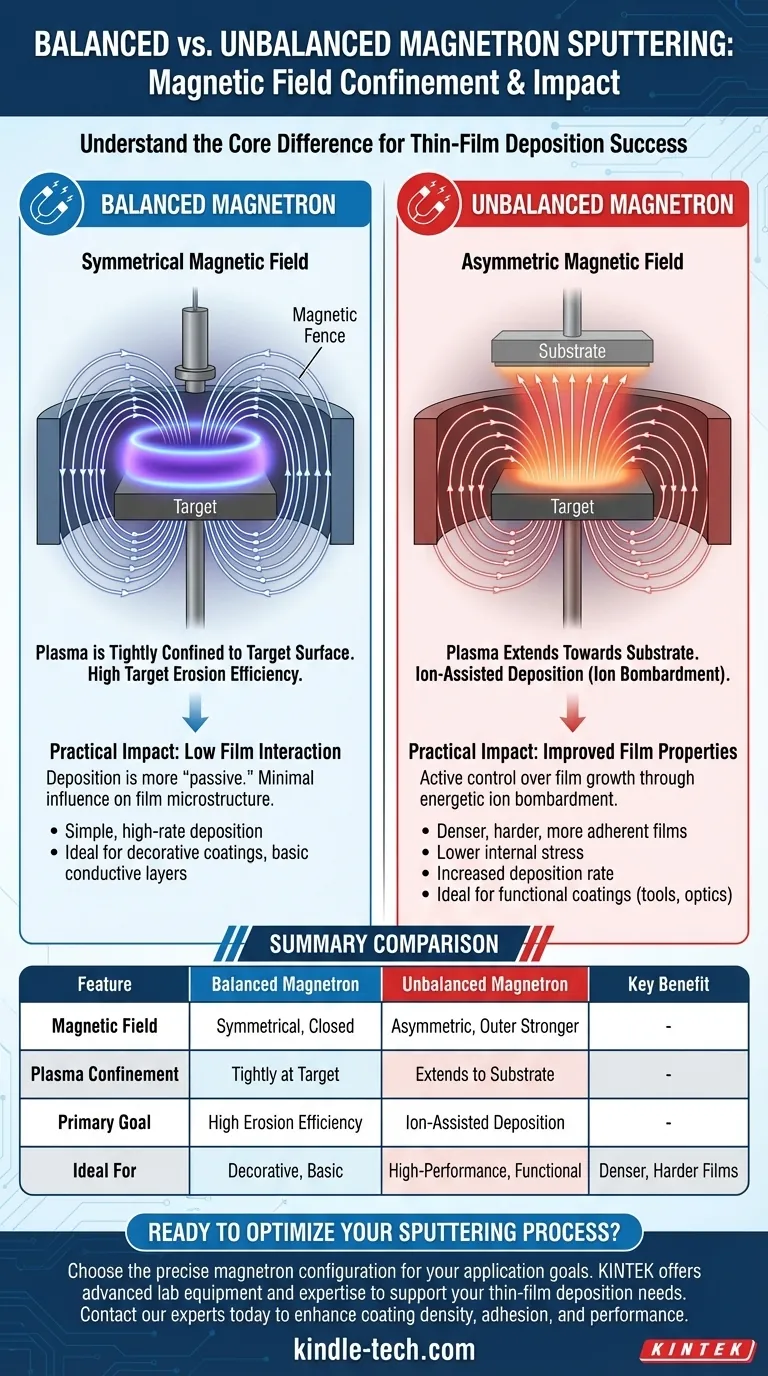

The Defining Difference: Magnetic Field Confinement

The function of any magnetron is to trap electrons in a magnetic field above a target material. These trapped electrons then ionize a process gas (like Argon), creating a dense plasma. The positive ions from this plasma are then accelerated into the negatively biased target, sputtering away atoms that travel to and coat your substrate. The magnetron's design dictates where this plasma is most concentrated.

How a Balanced Magnetron Works

In a standard balanced magnetron, the inner and outer magnetic poles are of roughly equal strength.

This creates a closed, symmetrical magnetic field that acts like a "magnetic fence," trapping the vast majority of the plasma in a tight ring directly over the target's surface. This configuration is highly efficient at eroding the target.

The Unbalanced Magnetron's Asymmetric Design

An unbalanced magnetron intentionally breaks this symmetry. The outer magnetic poles are made significantly stronger than the inner pole.

This causes some of the magnetic field lines, and the plasma that follows them, to "leak" or extend much further from the target and project out towards the substrate.

The Practical Impact on Film Deposition

This difference in magnetic field geometry is not academic; it has profound consequences for the material being deposited onto the substrate.

Enhanced Ion Bombardment

The key effect of an unbalanced design is that it guides a significant flux of ions from the plasma to the substrate. The substrate is essentially immersed in the plasma.

This means that as the film is growing, it is simultaneously being bombarded by energetic ions. This process is often called ion-assisted deposition.

Improved Film Properties

This simultaneous bombardment is the entire purpose of the unbalanced design. The extra energy delivered to the growing film can dramatically improve its physical properties.

Coatings deposited with an unbalanced magnetron are often denser, more adherent, and have lower internal stress. This is critical for applications requiring hard, wear-resistant, or optically precise films.

Increased Deposition Rate

By extending the plasma and improving its confinement within the process volume (especially in multi-magnetron systems), an unbalanced magnetron can also lead to a more efficient ionization process.

This often results in a higher overall deposition rate for the coating, delivering more material to the substrate in less time.

Understanding the Trade-offs

Neither design is universally superior. The choice depends entirely on the desired outcome for your coating.

Balanced Magnetron: High Target Efficiency, Low Film Interaction

A balanced magnetron is excellent for applications where you simply need to deposit a layer of material without specific structural requirements.

The trade-off is a lack of influence over the film's microstructure. The deposition is more "passive," which may be insufficient for high-performance functional coatings.

Unbalanced Magnetron: Active Film Growth, Potential Inefficiencies

An unbalanced magnetron gives you active control over the film's properties by using ion bombardment to engineer its structure as it grows.

The downside is that some plasma energy is directed at the substrate instead of the target, and the extended plasma can bombard chamber walls, which can introduce impurities if not managed correctly.

Making the Right Choice for Your Application

Your process goal dictates the correct magnetron configuration.

- If your primary focus is simple, high-rate deposition with minimal film modification: A balanced magnetron is the standard, efficient choice for applications like decorative coatings or basic conductive layers.

- If your primary focus is creating dense, hard, or highly adherent functional coatings: An unbalanced magnetron is essential to provide the ion bombardment needed to engineer the film's properties for applications like tool coatings or optical filters.

- If you are using a multi-target system for complex alloys or reactive sputtering: A closed-field unbalanced magnetron configuration, where the fields of adjacent magnetrons link up, offers the highest level of plasma confinement and process control.

Ultimately, understanding the magnetic field geometry empowers you to select the precise tool for controlling your thin-film deposition process.

Summary Table:

| Feature | Balanced Magnetron | Unbalanced Magnetron |

|---|---|---|

| Magnetic Field | Symmetrical, closed | Asymmetric, outer magnets stronger |

| Plasma Confinement | Tightly confined to target surface | Extends towards the substrate |

| Primary Goal | High target erosion efficiency | Ion-assisted deposition |

| Key Benefit | Simple, high-rate deposition | Denser, harder, more adherent films |

| Ideal For | Decorative coatings, basic conductive layers | High-performance functional coatings (tools, optics) |

Ready to Optimize Your Sputtering Process?

Choosing the right magnetron configuration is critical for achieving the precise film properties your application demands. Whether you need the high-rate efficiency of a balanced system or the superior film quality enabled by an unbalanced magnetron's ion bombardment, KINTEK has the expertise and equipment to support your goals.

KINTEK specializes in advanced lab equipment and consumables for thin-film deposition, serving research and industrial laboratories worldwide. Our team can help you select the ideal sputtering solution to enhance coating density, adhesion, and performance.

Contact our experts today to discuss your specific requirements and discover how our solutions can advance your research or production capabilities.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What are the disadvantages of plasma enhanced chemical vapor deposition? Managing the Trade-offs of Low-Temperature Deposition

- What is the speed of PECVD? Achieve High-Speed, Low-Temperature Deposition for Your Lab