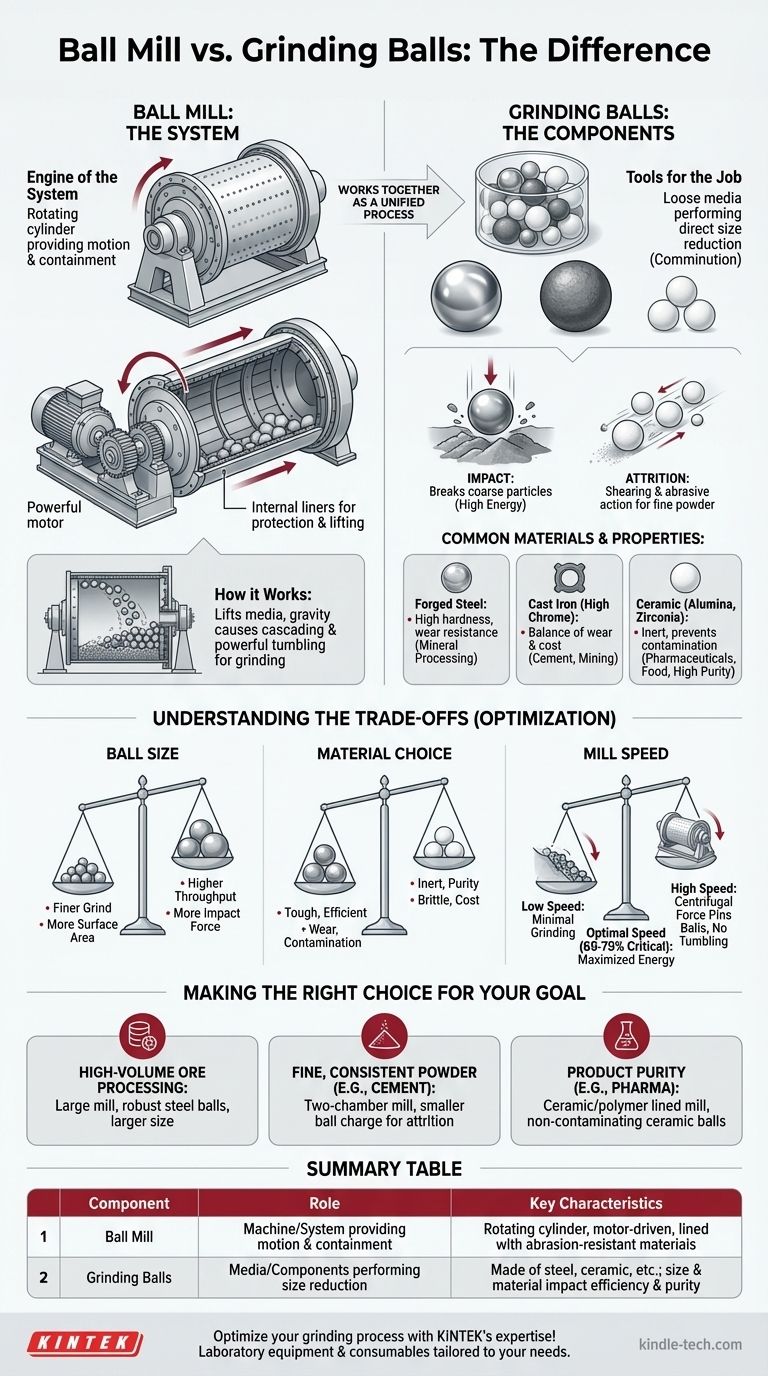

In short, a ball mill is the machine, and grinding balls are the media used inside that machine to perform the work. A ball mill is a type of grinder, a large rotating cylinder containing the material to be ground along with the grinding balls. The balls are the loose tools within the machine that crush and grind the material through impact and abrasion as the mill tumbles.

The core distinction is that of a system versus a component. The ball mill is the complete system that provides the energy and containment, while the grinding balls are the specific components within that system that directly apply the force to reduce particle size.

The Ball Mill: The Engine of the System

To understand the relationship, we must first define the machine itself. The ball mill is the primary piece of equipment responsible for creating the environment for grinding.

What is a Ball Mill?

A ball mill is a hollow cylindrical shell that rotates on its axis. It is partially filled with the material to be ground and the grinding media (the balls).

The interior of the shell is protected by abrasion-resistant liners. These liners not only protect the mill's structure from wear but also help lift the grinding media as the mill rotates.

How the Mill Works

The mill is driven by a powerful motor, causing the entire drum to rotate. This rotation lifts the grinding balls and the material up the side of the shell.

At a certain point, gravity overcomes the centrifugal force, and the balls cascade and tumble back down. It is this continuous, powerful tumbling action that generates the forces needed for grinding.

Grinding Balls: The Tools for the Job

While the mill provides the motion, the grinding balls are what actually perform the size reduction, a process known as comminution.

The Role of Grinding Balls

Grinding balls are the direct point of contact with the material. As they are lifted and fall within the rotating mill, they crush the material in two primary ways:

- Impact: Larger balls falling from greater heights create high-energy impacts, which are effective at breaking down larger, coarser particles.

- Attrition: As balls tumble over one another, they create a shearing and abrasive action, which is effective at grinding smaller particles into a fine powder.

Common Materials and Their Properties

The choice of grinding ball material is critical and depends entirely on the application.

- Forged Steel: The most common choice. It offers excellent hardness and high wear resistance, making it ideal for high-impact applications like mineral processing.

- Cast Iron (High Chrome): Offers a good balance of wear resistance and cost-effectiveness. It is widely used in the cement and mining industries.

- Ceramic (Alumina, Zirconia): Used when product contamination is a major concern, such as in the manufacturing of pharmaceuticals, food products, and high-purity ceramics. They are wear-resistant but can be more brittle than steel.

Understanding the Trade-offs

Optimizing a grinding process involves balancing several competing factors. The choices you make regarding the mill and the media have direct consequences on the outcome.

Ball Size: Finer Grind vs. Throughput

Using smaller balls increases the surface area and number of contact points, leading to a finer final product. However, smaller balls have less impact force and may not be able to break down very coarse feed material efficiently.

Using larger balls provides the high impact force needed to break coarse feed. This can increase throughput but typically results in a coarser final product. Often, a mix of sizes is used to achieve both effects.

Material Choice: Wear Resistance vs. Contamination

Steel balls are tough and efficient but will slowly wear down, introducing a small amount of iron contamination into the product. For mining or cement, this is irrelevant.

Ceramic balls are inert and prevent contamination, but they are generally more expensive and can be more susceptible to fracturing under extreme impact, making them unsuitable for some heavy-duty applications.

Mill Speed: Efficiency vs. Liner Wear

The speed at which the mill rotates is critical. If the speed is too low, the balls will just slide, causing minimal grinding. If it's too high (approaching critical speed), the balls will be pinned to the shell by centrifugal force and won't tumble at all.

Operating at the optimal speed (typically 65-75% of critical speed) maximizes the energy of the cascading balls. However, running at higher speeds to increase throughput will also accelerate wear on the mill liners and the grinding balls themselves.

Making the Right Choice for Your Goal

The effectiveness of a ball milling operation depends entirely on the synergy between the mill's parameters and the chosen grinding media.

- If your primary focus is high-volume ore processing: You will likely use a large-diameter mill with a robust charge of high-chrome or forged steel balls of a larger size to handle coarse feed.

- If your primary focus is producing a fine, consistent powder (e.g., cement): You may use a two-chamber mill or a smaller ball charge to promote attrition over high impact.

- If your primary focus is product purity (e.g., pharmaceuticals or fine chemicals): You must use a mill lined with ceramic or polymer and charge it with non-contaminating ceramic grinding balls.

Ultimately, understanding that the mill and its media are a single, interconnected system is the key to achieving efficient and effective size reduction.

Summary Table:

| Component | Role | Key Characteristics |

|---|---|---|

| Ball Mill | The machine/system that provides motion and containment. | Rotating cylinder, motor-driven, lined with abrasion-resistant materials. |

| Grinding Balls | The media/components that perform the size reduction. | Made of steel, ceramic, etc.; size and material impact grinding efficiency and product purity. |

Optimize your grinding process with KINTEK's expertise!

Whether you're processing minerals, manufacturing cement, or producing high-purity pharmaceuticals, the right combination of ball mill and grinding media is critical for your results. KINTEK specializes in providing high-quality lab equipment and consumables, including grinding balls and milling solutions tailored to your specific needs—ensuring efficiency, product purity, and cost-effectiveness.

Let our experts help you select the perfect grinding system for your application. Contact KINTEK today to discuss your laboratory requirements and achieve superior grinding performance!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Small Injection Molding Machine for Lab Use

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What is the function of a high-energy planetary ball mill in zirconium-doped CaO synthesis? Optimize Material Stability

- How does a planetary high-energy ball mill contribute to the top-down preparation of layered materials? Optimize Yield

- Why is a high-energy planetary ball mill preferred over traditional casting for nanocrystalline HEAs?

- Why are high-intensity planetary ball mills preferred for reducing the crystallinity of lignocellulose?

- What is the role of a planetary ball mill in the preparation of NiCr-Al2O3-SrCO3 composite powders? Enhanced Homogeneity