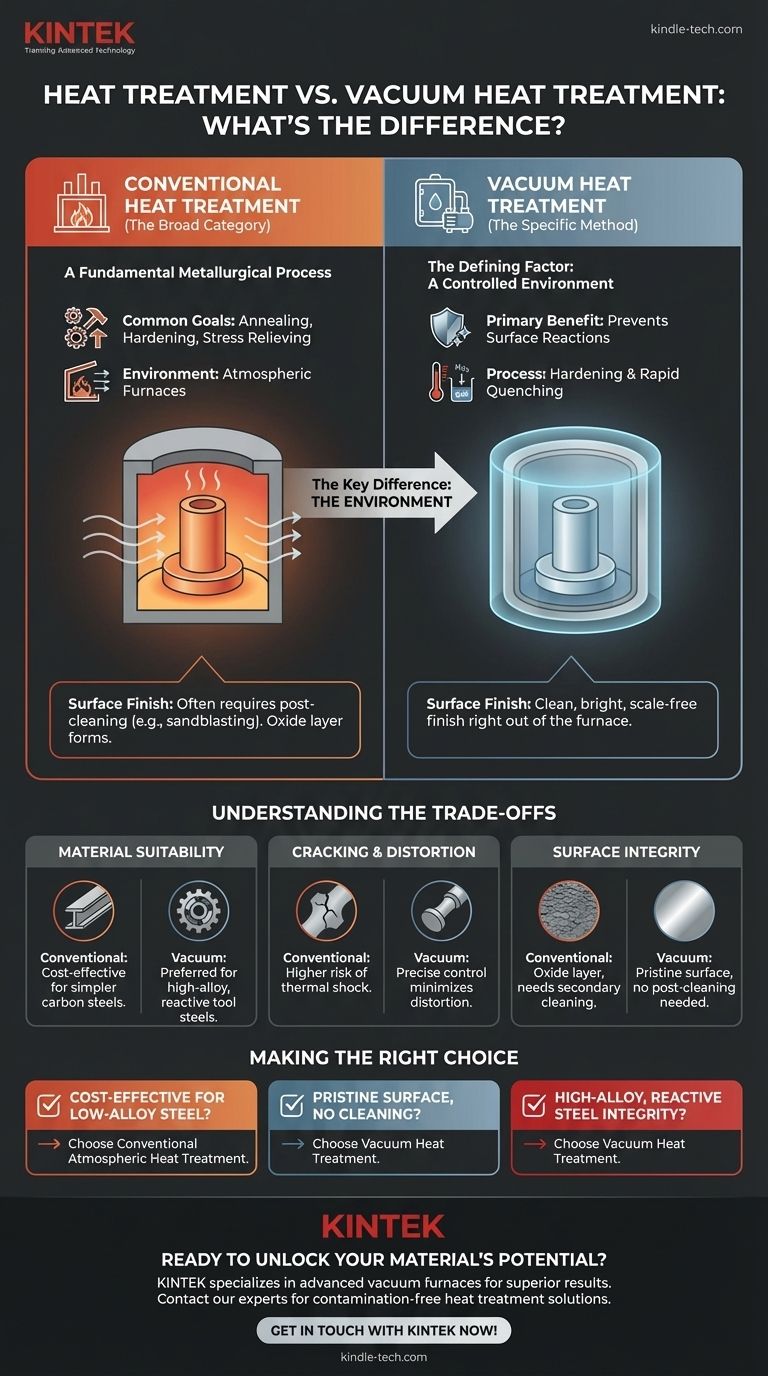

The fundamental difference is that "heat treatment" is a broad category of processes used to alter a material's physical properties, while "vacuum heat treatment" is a specific method within that category. The defining characteristic of the vacuum method is that the process occurs inside a furnace where the air has been removed, creating a controlled, contamination-free environment.

The choice between conventional and vacuum heat treatment is not about the goal, but the environment. Vacuum heat treatment is selected when protecting the material's surface from atmospheric contamination is critical to achieving the desired final properties.

What is Heat Treatment? (The Broad Category)

A Fundamental Metallurgical Process

Heat treatment refers to any of a group of controlled heating and cooling processes used to change the microstructure of a metal or alloy.

This controlled thermal cycling intentionally modifies properties like hardness, strength, toughness, ductility, and elasticity without changing the part's shape.

Common Goals and Methods

The goals of heat treatment are diverse. Common processes include annealing to soften a material, hardening to increase its strength, and stress relieving to reduce internal tensions created during manufacturing.

The Conventional Environment

Most conventional heat treatment methods are performed in atmospheric furnaces. This means the parts are exposed to the ambient air (composed of oxygen, nitrogen, and other elements) during the heating cycle.

What is Vacuum Heat Treatment? (The Specific Method)

The Defining Factor: A Controlled Environment

Vacuum heat treatment is a process performed in a sealed furnace chamber where the air and other gases have been pumped out to create a vacuum.

This low-pressure environment is the key differentiator. By removing atmospheric elements, especially oxygen, we can prevent chemical reactions from occurring on the metal's surface at high temperatures.

The Primary Benefit: Preventing Surface Reactions

The main purpose of using a vacuum is to prevent undesirable surface reactions like oxidation (scaling) and decarburization (the loss of carbon from the surface of steel).

This results in parts that emerge from the furnace with a clean, bright, and unaltered surface, often eliminating the need for subsequent cleaning operations.

A High-Performance Hardening Process

While it can be used for other goals, vacuum heat treatment is most commonly a hardening process for higher-end materials.

Parts are heated to a specific high temperature in the vacuum and then rapidly cooled (quenched) using inert gas, oil, or polymer to achieve the final desired hardness.

Understanding the Trade-offs

Surface Finish and Cleanliness

Vacuum-treated parts have a superior, scale-free surface finish right out of the furnace. Conventional methods often leave an oxide layer that must be removed through secondary processes like sandblasting or grinding.

Material Suitability

Vacuum heat treatment is the preferred, and often necessary, method for high-alloy tool steels and other reactive materials that are highly susceptible to surface contamination. Conventional methods are typically sufficient and more cost-effective for simpler carbon steels.

Cracking and Distortion

The highly controlled heating and cooling cycles possible in a vacuum furnace can reduce thermal shock. This precise control often minimizes the risk of cracking or distortion, especially in complex part geometries.

Making the Right Choice for Your Application

Choosing the correct heat treatment method is essential for ensuring the performance and longevity of the final component. Your decision should be guided by the material being used and the required surface integrity.

- If your primary focus is cost-effectiveness for low-alloy carbon steels: Conventional atmospheric heat treatment is usually the most practical choice.

- If your primary focus is a pristine surface finish that requires no secondary cleaning: Vacuum heat treatment is the superior option.

- If your primary focus is the integrity of high-alloy, reactive, or tool steels: Vacuum heat treatment is necessary to prevent surface degradation and ensure optimal performance.

Ultimately, selecting the right thermal processing environment is key to unlocking a material's full potential.

Summary Table:

| Feature | Conventional Heat Treatment | Vacuum Heat Treatment |

|---|---|---|

| Environment | Atmospheric Furnace (Air) | Sealed Vacuum Chamber |

| Surface Finish | Often requires post-cleaning (e.g., sandblasting) | Clean, bright, scale-free finish |

| Ideal For | Cost-effective processing of simpler carbon steels | High-alloy tool steels & reactive materials |

| Primary Benefit | General purpose property alteration | Prevents oxidation & decarburization |

Ready to unlock your material's full potential with precision thermal processing?

At KINTEK, we specialize in providing advanced laboratory equipment, including vacuum furnaces, to ensure your high-alloy steels and sensitive materials receive the contamination-free heat treatment they require. Our solutions help you achieve superior hardness, minimize distortion, and eliminate costly secondary cleaning steps.

Contact our experts today to discuss how our lab equipment and consumables can enhance your research and production outcomes.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- How does argon and nitrogen cooling compare in vacuum furnaces? A Guide to Faster, Cheaper Quenching

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs