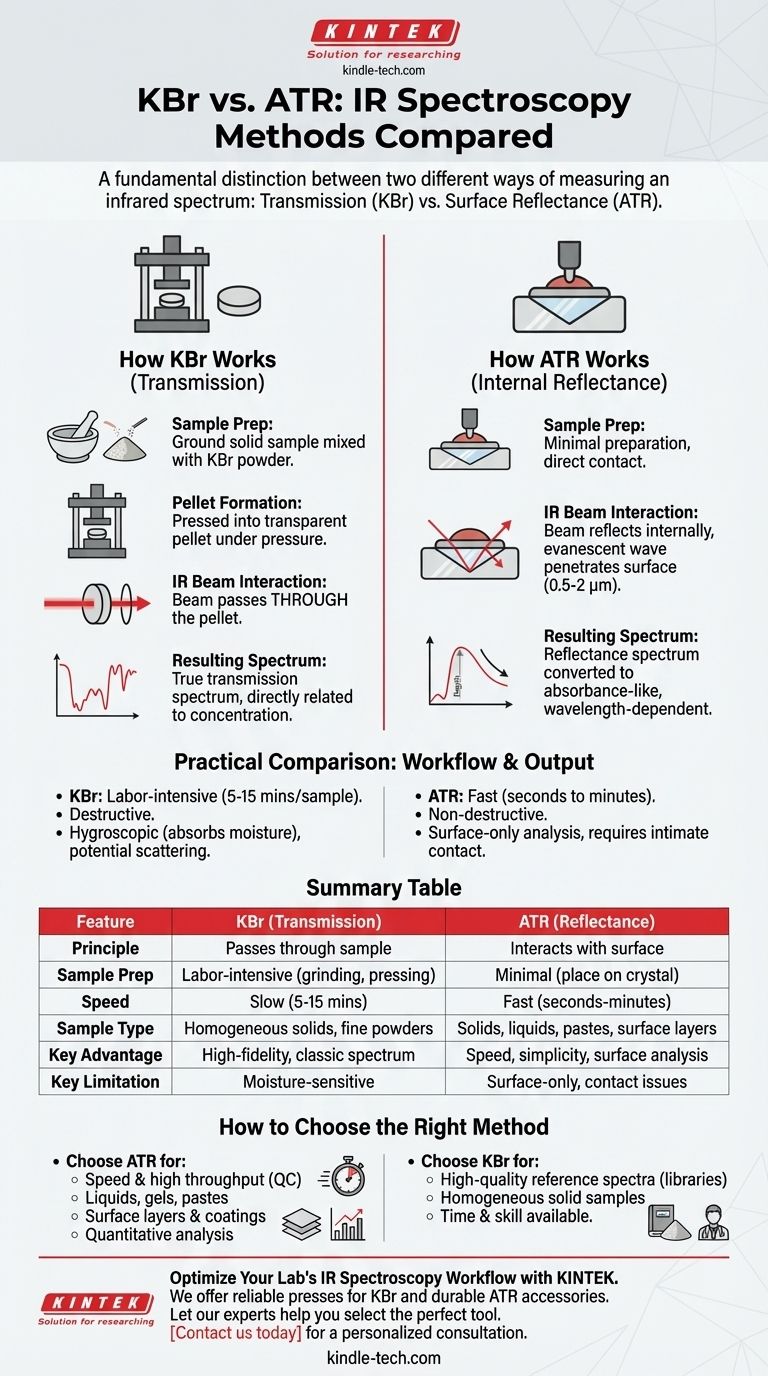

At its core, the difference between KBr and ATR is a distinction between two fundamentally different ways of measuring an infrared spectrum. The KBr pellet method is a transmission technique where the IR beam passes through a prepared sample, while Attenuated Total Reflectance (ATR) is a surface reflectance technique where the IR beam interacts only with the very top layer of the sample.

The central decision between KBr and ATR is a trade-off: The KBr method provides a classic, high-fidelity transmission spectrum but requires significant sample preparation and skill. ATR offers unmatched speed and simplicity but analyzes only the sample's surface and can introduce predictable spectral variations.

Understanding the Fundamental Principles

To choose the right method, you must first understand how each one generates a spectrum. They are not interchangeable, and the physics behind them dictates their strengths and weaknesses.

How the KBr Pellet Method Works (Transmission)

The Potassium Bromide (KBr) pellet method is a classic transmission technique. First, a small amount of solid sample is ground into an extremely fine powder.

This powder is then intimately mixed with dry, IR-grade KBr powder. KBr is used because it is transparent to infrared radiation and, under pressure, forms a solid, glass-like disc.

This mixture is pressed under high vacuum and pressure to form a small, transparent pellet. The IR beam is then passed directly through this pellet, and the detector measures which frequencies of light were absorbed by the sample.

How ATR Works (Internal Reflectance)

Attenuated Total Reflectance (ATR) is a surface analysis technique that requires an ATR accessory, typically featuring a high-refractive-index crystal (like diamond, zinc selenide, or germanium).

The sample (solid or liquid) is pressed into direct contact with this crystal. The IR beam is directed into the crystal at an angle, causing it to reflect internally.

At each point of reflection, an electromagnetic wave called an evanescent wave penetrates a very short distance (typically 0.5 to 2 microns) beyond the crystal's surface and into your sample. If the sample absorbs IR at specific frequencies, it attenuates this wave, and the resulting reflected beam carries the spectral information to the detector.

Practical Comparison: Workflow and Spectral Output

The day-to-day experience and the resulting data from these two methods are vastly different.

Sample Preparation: The Biggest Divide

The KBr method is labor-intensive. It requires careful grinding, weighing, mixing, and pressing. The entire process can take 5-15 minutes per sample for an experienced user and is destructive to the sample.

ATR, in contrast, involves virtually no sample preparation. You place the sample on the crystal, apply pressure using a built-in clamp, and run the scan. Cleaning the crystal with a solvent-moistened swab takes seconds.

Resulting Spectrum: Transmission vs. Absorbance

A KBr spectrum is a "true" transmission spectrum, which is often the standard format found in historical spectral libraries. The peak intensities are directly related to the concentration of functional groups along the beam path.

An ATR spectrum is technically a reflectance spectrum, though software converts it to a format that looks like an absorbance spectrum. However, a key artifact remains: the penetration depth of the evanescent wave is wavelength-dependent. It penetrates deeper at longer wavelengths (lower wavenumbers), causing peaks in that region to appear relatively more intense than they would in a KBr spectrum. Modern software can apply a correction for this.

Understanding the Trade-offs and Pitfalls

Neither method is perfect. Your success depends on understanding their inherent limitations.

The Moisture Problem with KBr

KBr is highly hygroscopic, meaning it readily absorbs water from the atmosphere. If your KBr powder is not kept perfectly dry, or if you prepare the pellet in a humid environment, you will see large, broad peaks for O-H stretching (~3400 cm⁻¹) and H-O-H bending (~1640 cm⁻¹) that can obscure your actual sample's peaks.

The Surface Sensitivity of ATR

ATR only analyzes the top few microns of a sample. This is a significant advantage for analyzing surface layers, coatings, or opaque materials. However, if your sample is inhomogeneous (e.g., a polymer with a surface additive), the ATR spectrum will not be representative of the bulk material.

The Contact Problem with ATR

For ATR to work, the sample must make intimate contact with the crystal. For hard, irregular solids, it can be difficult to achieve enough contact, leading to a weak or distorted spectrum. Soft powders and liquids do not have this problem.

Grinding and Scattering in KBr

If the sample is not ground finely enough for the KBr pellet, its particles can scatter the IR beam. This often results in a sloping baseline and distorted peak shapes, a phenomenon known as the Christiansen effect.

How to Choose the Right Method

Your choice should be dictated by your sample type, analytical goal, and required throughput.

- If your primary focus is speed and high throughput: Choose ATR. It is the go-to method for routine quality control and rapid screening of many samples.

- If your primary focus is creating a high-quality reference spectrum for a library or publication: Use the KBr pellet method, provided you have the time and skill to prepare a good pellet.

- If your sample is a liquid, gel, or paste: ATR is vastly superior. It's fast, clean, and requires no dilution or special cells.

- If you are analyzing a surface, laminate, or coating: ATR is the only option of the two, as it is inherently a surface technique.

- If you are performing quantitative analysis: ATR is often preferred because the sampling path length is constant and reproducible, whereas the path length of a KBr pellet depends on its thickness.

Ultimately, the right choice depends on balancing the need for analytical purity against the demands of practical efficiency.

Summary Table:

| Feature | KBr (Transmission) | ATR (Reflectance) |

|---|---|---|

| Principle | IR beam passes through sample | IR beam interacts with sample surface |

| Sample Prep | Labor-intensive (grinding, pressing) | Minimal (place sample on crystal) |

| Speed | Slow (5-15 mins/sample) | Fast (seconds to minutes) |

| Sample Type | Homogeneous solids, fine powders | Solids, liquids, pastes, surface layers |

| Key Advantage | High-fidelity, classic spectrum | Speed, simplicity, surface analysis |

| Key Limitation | Hygroscopic, moisture-sensitive | Surface-only, requires good contact |

Optimize Your Lab's IR Spectroscopy Workflow with KINTEK

Choosing between KBr and ATR is critical for accurate and efficient material analysis. Whether you need the high-fidelity reference spectra of the KBr method or the rapid, versatile analysis of ATR, KINTEK has the right lab equipment for you.

We specialize in providing reliable IR spectroscopy solutions, including presses for KBr pellet preparation and durable ATR accessories, to meet the diverse needs of research and quality control laboratories.

Let our experts help you select the perfect tool to enhance your lab's efficiency and accuracy.

Contact us today for a personalized consultation!

Visual Guide

Related Products

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- What is the KBr method in IR spectroscopy? A Guide to Solid Sample Analysis

- How do you prepare KBr pellets for FTIR analysis? Master the Technique for High-Quality IR Spectra

- What is a KBr pellet? A Guide to Preparing Solid Samples for IR Spectroscopy

- Why only KBr is used in IR spectroscopy? The Truth About the Best Material for Your Sample

- How do you do the KBr pellet method? A Step-by-Step Guide to Perfect FTIR Sample Preparation