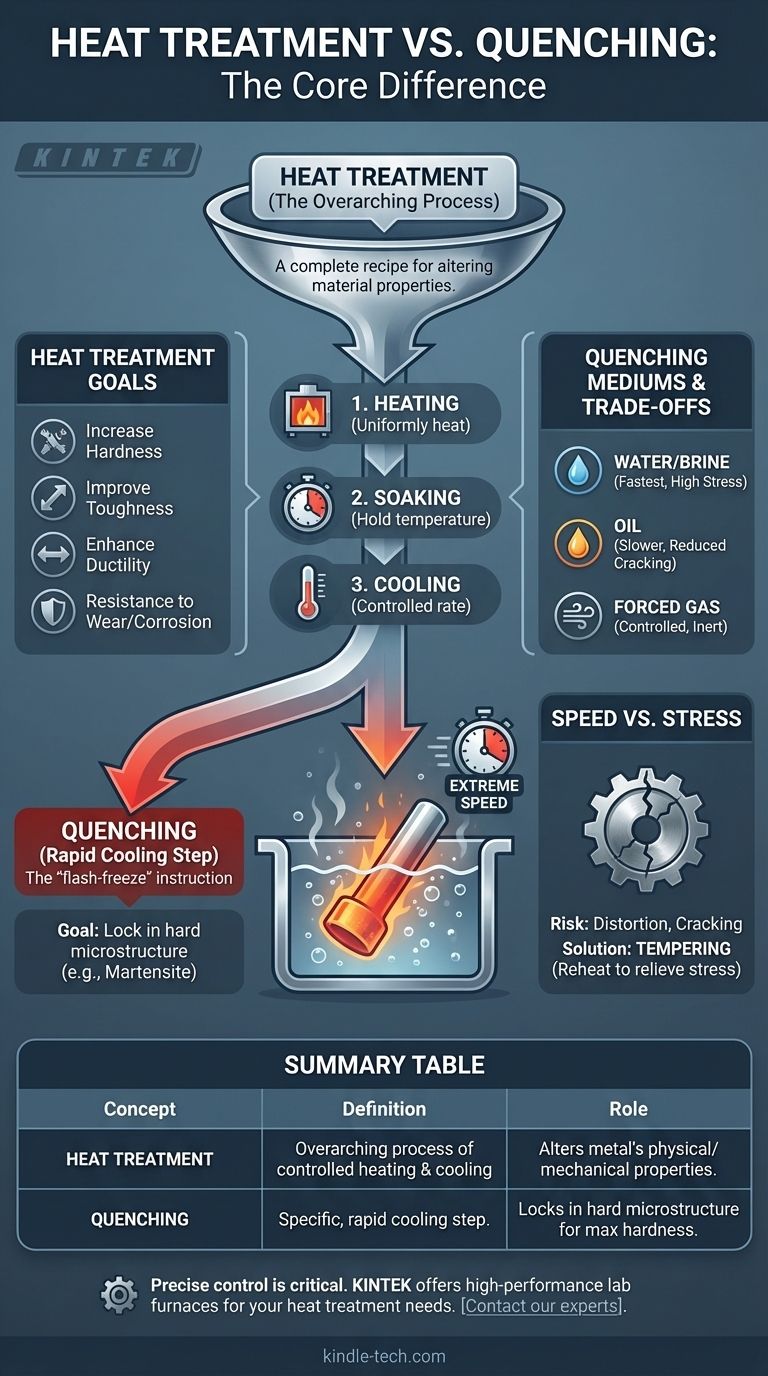

In metallurgy, the key distinction is one of hierarchy and scope. Heat treatment is the entire, overarching process of using controlled heating and cooling to alter a material's physical and mechanical properties. Quenching is not a separate process, but rather a specific, and often the most critical, step within a heat treatment procedure: the rapid cooling phase.

Think of heat treatment as a complete recipe for a metal. Quenching is one specific, high-impact instruction in that recipe—like flash-freezing an ingredient—while other instructions might call for slow-baking or air-cooling.

What is Heat Treatment? The Broader Framework

Heat treatment is the disciplined practice of manipulating a metal's internal crystalline structure to achieve a desired outcome. This allows engineers to take a single alloy and produce a wide range of properties from it.

The Goal: Manipulating Properties

The fundamental purpose of heat treatment is to change a metal's characteristics. This includes increasing its hardness, improving its toughness, enhancing its ductility, or increasing its resistance to wear and corrosion.

The Three Core Stages

Nearly all heat treatments consist of three fundamental stages:

- Heating: The metal is slowly and uniformly heated to a specific, predetermined temperature.

- Soaking: The metal is held at this temperature for a set period to ensure its entire structure reaches a uniform state.

- Cooling: The metal is cooled back to room temperature at a controlled rate. The speed of this stage is where processes like quenching are defined.

Where Quenching Fits In: The Cooling Phase

Quenching is defined by one primary factor: speed. It is a method of extremely rapid cooling from the high temperature of the soaking phase.

The Purpose of Speed

The rapid cooling of a quench is designed to "lock in" a specific microscopic structure that would otherwise disappear if the metal were allowed to cool slowly. In ferrous alloys like steel, this traps carbon in a hard, brittle crystalline structure known as martensite, which is essential for making tools, springs, and wear-resistant parts.

Common Quenching Methods

The method of quenching is chosen based on the alloy and the desired cooling rate. Common quenching mediums, or "quenchants," include:

- Water or Brine: Provides an extremely fast cooling rate, but can induce high internal stress.

- Oil: Cools less rapidly than water, reducing the risk of cracking or warping for many steel alloys.

- Forced Air or Gas: In vacuum furnaces, inert gases like nitrogen or argon can be blown over the part for controlled, rapid cooling without the risk of oxidation.

Understanding the Trade-offs: Speed vs. Stress

While quenching is essential for achieving high hardness, this rapid, transformative process is not without its risks. The speed of the cooling introduces significant internal stresses.

The Risk of Distortion and Cracking

As different parts of the metal cool and shrink at different rates, immense internal forces are generated. If not properly managed, these stresses can cause the component to warp, distort, or even crack.

The Need for Tempering

A quenched part, particularly steel, is often too brittle for practical use. Therefore, quenching is almost always followed by another heat treatment step called tempering. This involves reheating the part to a lower temperature to relieve internal stresses and restore some toughness, albeit at the cost of some hardness.

Making the Right Choice for Your Goal

The terms are not interchangeable; one is a component of the other. Your goal determines which type of cooling phase is required within the overall heat treatment process.

- If your primary focus is achieving maximum hardness (e.g., for cutting tools): Your heat treatment plan will depend on quenching to create the necessary hardened microstructure.

- If your primary focus is softening a metal to make it more workable (annealing): Your heat treatment will use a very slow cooling phase, the direct opposite of quenching.

- If your primary focus is improving the toughness of a hardened part: Your process will involve quenching first, followed immediately by a secondary tempering heat treatment.

Ultimately, understanding that quenching is a tool within the larger heat treatment toolkit is the key to engineering the precise material properties a project demands.

Summary Table:

| Concept | Definition | Role in Metallurgy |

|---|---|---|

| Heat Treatment | Overarching process of controlled heating & cooling | Alters metal's physical/mechanical properties (hardness, toughness) |

| Quenching | A specific, rapid cooling step within heat treatment | Locks in hard microstructure (e.g., martensite) for maximum hardness |

Need precise control over your material properties? The right lab equipment is critical for successful heat treatment processes like quenching and tempering. KINTEK specializes in high-performance lab furnaces and consumables that deliver the exact heating and cooling rates your metallurgy work demands. Contact our experts today to find the perfect solution for your laboratory's needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost