The fundamental difference lies in the physical state of the material during the process. Solid-state sintering bonds particles together entirely in the solid phase through atomic diffusion, requiring temperatures just below the material's melting point. In contrast, liquid-state sintering introduces a small amount of a liquid phase that acts as a bonding agent, accelerating densification and allowing the process to occur at lower temperatures.

The choice between these two methods hinges on a critical trade-off: Solid-state sintering is ideal for material purity, while liquid-state sintering is superior for achieving high density quickly by using a liquid to transport material and rearrange particles.

The Mechanism of Solid-State Sintering

Solid-state sintering is the conceptually simpler of the two processes, relying on the natural tendency of atoms to move and minimize energy. It is the go-to method for pure, single-component materials.

The Core Principle: Atomic Diffusion

In this process, a compacted powder is heated to a high temperature, but always remains below its melting point. At this elevated temperature, atoms gain enough energy to migrate across the boundaries of adjacent particles.

This atomic movement gradually fills the voids, or pores, between particles. The contact points between particles, known as "necks," grow over time, fusing the individual particles into a solid, coherent mass.

The Driving Force: Reducing Surface Energy

Powdered materials have an enormous amount of surface area, which corresponds to a high state of surface energy. The universe favors lower energy states.

By bonding together and reducing the total amount of exposed surface, the particles achieve a more stable, lower-energy state. This reduction in surface energy is the fundamental driving force behind solid-state sintering.

The Mechanism of Liquid-State Sintering

Liquid-state sintering is a more complex but often more efficient process. It introduces a secondary material that melts during heating, dramatically changing the dynamics of densification.

The Role of the Liquid Additive

This process involves a primary powder mixed with a small amount of an additive. The sintering temperature is chosen to be above the melting point of the additive but below that of the primary material.

This creates a small volume of liquid that coats the solid particles. This liquid phase is the key to the process's speed and effectiveness.

Step 1: Particle Rearrangement

The liquid wets the solid particles, and capillary forces pull them together tightly. This action physically rearranges the particles into a more compact and dense configuration, rapidly eliminating larger pores.

Step 2: Solution-Reprecipitation

At the points where solid particles are pressed together, the pressure is high. This high pressure increases the solubility of the solid material in the liquid.

The solid material dissolves into the liquid at these contact points and then re-precipitates in low-pressure areas, such as the neck regions between particles. This mechanism efficiently transports material to fill voids and strongly weld the particles together.

Understanding the Trade-offs

Choosing between solid-state and liquid-state sintering is not about which is "better," but which is appropriate for the specific material and desired outcome.

Speed vs. Purity

Liquid-state sintering is significantly faster because the liquid phase provides a high-speed pathway for material transport, compared to the slow crawl of atomic diffusion in the solid state.

However, this speed comes at the cost of purity. The additive that forms the liquid becomes a permanent part of the final material's microstructure, which may be undesirable for certain applications.

Final Density vs. Simplicity

Liquid-state sintering typically achieves higher final densities and lower porosity. The capillary action and solution-reprecipitation are extremely effective at eliminating voids.

Solid-state sintering is a simpler process to control for pure materials. It avoids complications related to wetting, viscosity, and potential unwanted chemical reactions between the liquid and solid phases.

Making the Right Choice for Your Goal

Your application's specific requirements will dictate the correct sintering method.

- If your primary focus is material purity and a single-component system: Solid-state sintering is the necessary choice as it avoids any additives.

- If your primary focus is achieving maximum density and low porosity quickly: Liquid-state sintering is almost always the more effective and efficient option.

- If you are working with materials that are difficult to densify (e.g., ceramics, refractory metals): Liquid-state sintering provides a powerful mechanism to achieve densification where solid-state methods might fail.

Ultimately, understanding the transport mechanism—slow diffusion versus rapid liquid-assisted transport—empowers you to select the ideal process for your manufacturing goal.

Summary Table:

| Feature | Solid-State Sintering | Liquid-State Sintering |

|---|---|---|

| Material State | Entirely solid phase | Liquid phase present (from additive) |

| Primary Mechanism | Atomic diffusion | Particle rearrangement & solution-reprecipitation |

| Speed | Slower | Faster |

| Final Density | Lower | Higher |

| Material Purity | High (no additives) | Lower (contains additive) |

| Ideal For | Pure, single-component materials | Difficult-to-densify materials, rapid production |

Struggling to choose the right sintering process for your materials? KINTEK specializes in providing the precise lab equipment and consumables needed for both solid-state and liquid-state sintering. Our experts can help you select the right furnace and materials to achieve your goals for purity, density, and efficiency. Contact us today (#ContactForm) to optimize your sintering process and enhance your lab's capabilities!

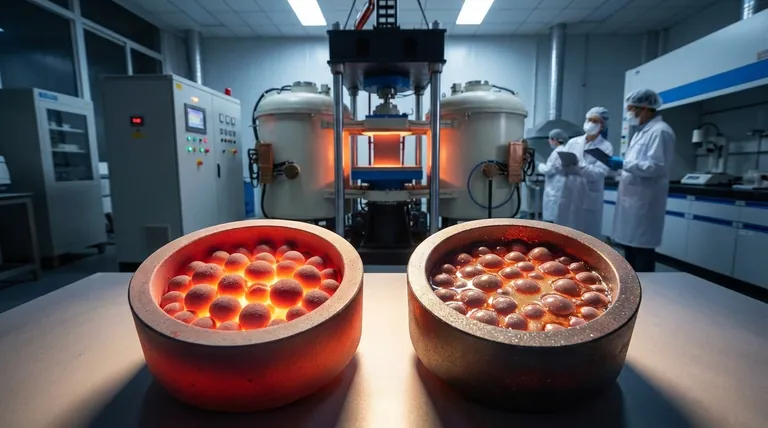

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Dental Porcelain Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the difference between a retort and a muffle furnace? Uncover the Truth About Indirect Heating

- How does a high-precision heat treatment furnace contribute to GBE? Enhance Supercritical Water Corrosion Resistance

- What are 2 uses of oven in the laboratory? Essential for Sterilization and Drying

- How is the ash content determined in a muffle furnace? Master the Gravimetric Analysis Method

- Why is a box-type high-temperature resistance furnace used for T-POMs@ZIF-67? Master MOF-to-Catalyst Pyrolysis

- What role do muffle or tube furnaces play in Ni-Mn-Sn-In alloy processing? Achieve Precise Material Transformation

- What are the different types of heat treatment process for steel? Tailor Strength, Hardness & Toughness

- What is the operation temperature of the muffle furnace? A Guide to Internal and Ambient Ranges