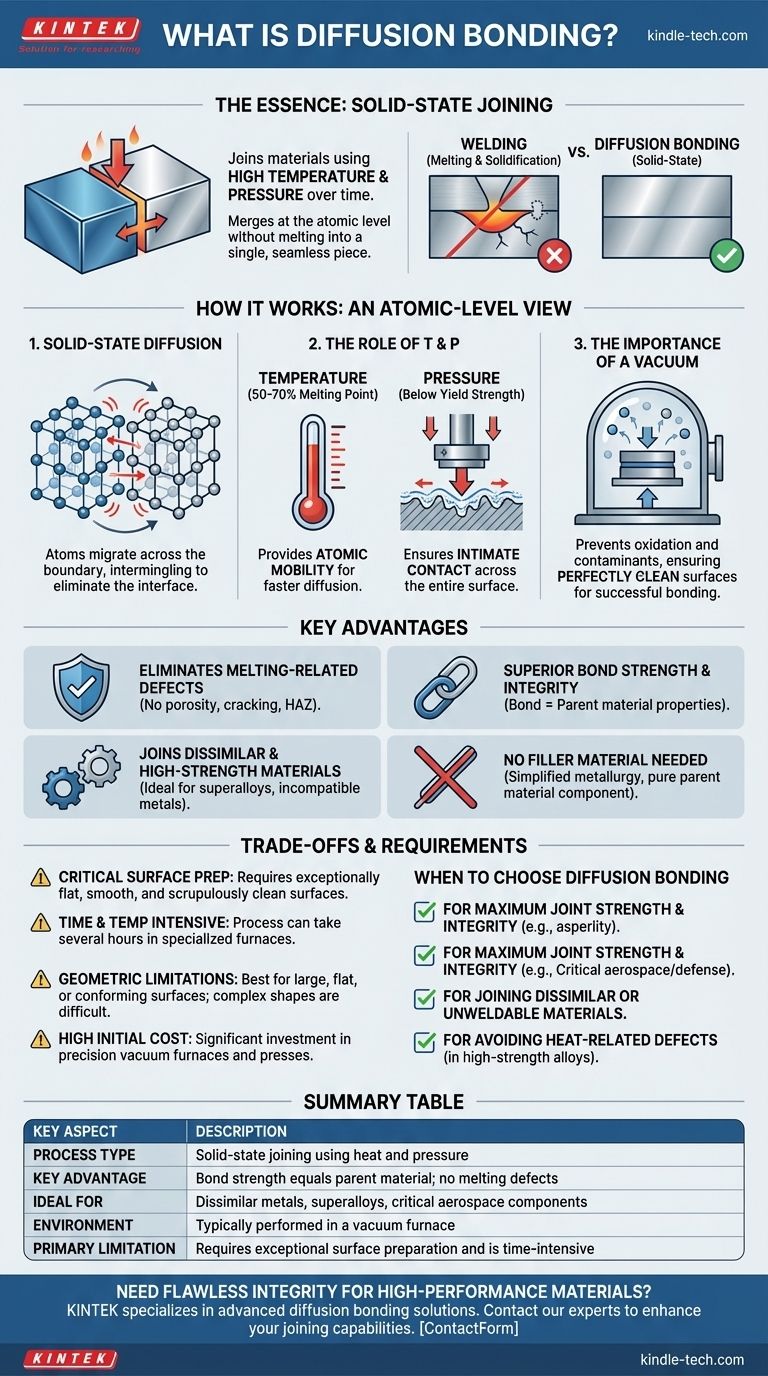

In essence, diffusion bonding is a solid-state joining process that merges materials by applying high temperature and pressure over time. Unlike welding, this method joins components without ever melting them, causing the atoms from each surface to intermingle and form a single, seamless piece. This eliminates defects associated with melting and solidification.

The true value of diffusion bonding isn't just joining parts; it's creating a bond that is indistinguishable from the parent material itself. This makes it the definitive solution for high-consequence applications involving materials that are otherwise impossible to join with conventional methods.

How Diffusion Bonding Works: An Atomic-Level View

To understand why this process is so effective, you must think at the atomic level. The goal is to make two separate pieces of metal believe they are, and have always been, a single continuous block.

The Core Principle: Solid-State Diffusion

Atoms in a solid material are not static; they vibrate in place. As you increase the temperature, this vibration becomes more energetic.

Diffusion bonding harnesses this energy. It forces two pristine surfaces together, and with sufficient heat, atoms from one surface begin to migrate across the boundary and into the crystalline structure of the other piece. Over time, this atomic exchange completely eliminates the original interface.

The Role of Temperature and Pressure

Temperature provides the atomic mobility needed for diffusion to occur. The higher the temperature (typically 50-70% of the material's melting point), the faster the atoms can move and the quicker the bond forms.

Pressure provides the intimate contact. No surface is perfectly flat. Pressure is applied to deform these microscopic peaks and valleys (asperities), ensuring the two surfaces make complete contact so atomic diffusion can occur across the entire interface. Crucially, this pressure remains well below the material's yield strength, preventing any change to the part's overall shape.

The Importance of a Vacuum

Most high-integrity diffusion bonding is performed in a vacuum. A vacuum environment is critical because it prevents surface oxidation at elevated temperatures.

Oxides and other surface contaminants act as a barrier that physically blocks atoms from migrating across the interface. By removing air, a vacuum furnace ensures the metal surfaces remain perfectly clean, which is non-negotiable for a successful bond.

Key Advantages Over Traditional Joining

Diffusion bonding is chosen when the limitations of other methods, like welding or brazing, are unacceptable.

Eliminating Melting-Related Defects

Because no melting occurs, diffusion bonding completely avoids common welding defects like porosity (gas bubbles), solidification cracking, and distortion. It also creates no significant heat-affected zone (HAZ), a weakened area of metal next to a weld.

Superior Bond Strength and Integrity

The resulting bond is not a separate layer of material; it is a continuation of the parent metals' own grain structure. A properly executed diffusion bond can exhibit the same mechanical, thermal, and electrical properties as the base material itself.

Joining Dissimilar and High-Strength Materials

This process is a primary solution for joining materials that are metallurgically incompatible for fusion welding. It is also exceptionally effective for high-strength superalloys and refractory metals (like tungsten and molybdenum) that are easily damaged by the intense, localized heat of welding.

No Filler Material Needed

Traditional welding often requires a filler rod, and brazing requires a filler metal that melts at a lower temperature. Diffusion bonding uses no filler, which simplifies the metallurgy and ensures the final component consists only of the intended parent materials.

Understanding the Trade-offs and Requirements

While powerful, diffusion bonding is not a universal solution. Its precision comes with specific demands.

The Critical Need for Surface Preparation

The process is highly intolerant of surface imperfections. The mating surfaces must be machined to be exceptionally flat and smooth, and they must be scrupulously cleaned to remove any oils, oxides, or contaminants before bonding.

A Time and Temperature Intensive Process

Diffusion is not an instantaneous event. A typical bonding cycle inside a specialized vacuum furnace or hot press can take several hours to complete, making it much slower than conventional welding.

Geometric and Size Limitations

The method works best for parts with large, flat, or conforming mating surfaces where uniform pressure can be applied. Complex, non-planar geometries can be very difficult or impossible to bond effectively. However, the process is suitable for very large workpieces if the equipment can handle them.

High Initial Cost

The specialized equipment required—precision vacuum furnaces and hydraulic presses—represents a significant capital investment. This often positions diffusion bonding as a solution for high-value components where performance justifies the cost.

When to Choose Diffusion Bonding

Your choice depends entirely on your project's technical requirements and constraints.

- If your primary focus is maximum joint strength and integrity: Choose diffusion bonding when the bond must be as strong and reliable as the parent material, especially for critical aerospace or defense components.

- If your primary focus is joining dissimilar or unweldable materials: This is the premier method for creating strong, hermetic bonds between metals that are incompatible with fusion welding.

- If your primary focus is avoiding heat-related defects: Select diffusion bonding to eliminate issues like porosity, cracking, and weakened zones that are common in welding high-strength alloys.

- If your primary focus is speed and low cost for simple joints: Conventional welding or brazing is a far more practical and economical choice for non-critical applications using standard materials.

Ultimately, diffusion bonding empowers you to create components that are impossible to manufacture by any other means.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Solid-state joining using heat and pressure |

| Key Advantage | Bond strength equals parent material; no melting defects |

| Ideal For | Dissimilar metals, superalloys, critical aerospace components |

| Environment | Typically performed in a vacuum furnace |

| Primary Limitation | Requires exceptional surface preparation and is time-intensive |

Need to join high-performance or dissimilar materials with flawless integrity? KINTEK specializes in advanced thermal processing solutions, including diffusion bonding systems. Our precision vacuum furnaces and expert support ensure you achieve bonds that are as strong as the parent material itself—perfect for aerospace, defense, and high-value component manufacturing. Contact our experts today to discuss how we can enhance your joining capabilities.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Dental Porcelain Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- What role does the high vacuum environment play in sintering graphite film/aluminum composites? Optimize Your Bonding

- How does the programmed temperature control of a hot pressing sintering furnace impact nanocopper? Master the Microstructure

- What is the sintering process of hot pressing? Achieve Maximum Density and Complex Shapes

- What are the benefits of using a vacuum hot pressing furnace to synthesize high-density Mo2Ga2C? Achieve 98.8% Density.

- What are the different types of hot pressing? Uniaxial, HIP, and SPS Explained

- What technical advantages does a Spark Plasma Sintering (SPS) furnace offer for LZP ceramics? Enhance Ionic Conductivity

- What is the necessity of pre-pressing composite powders? Enhance Stability in Vacuum Hot-Pressing Sintering

- How does a vacuum hot-press furnace facilitate the densification of boron carbide ceramics? Achieve Maximum Density.