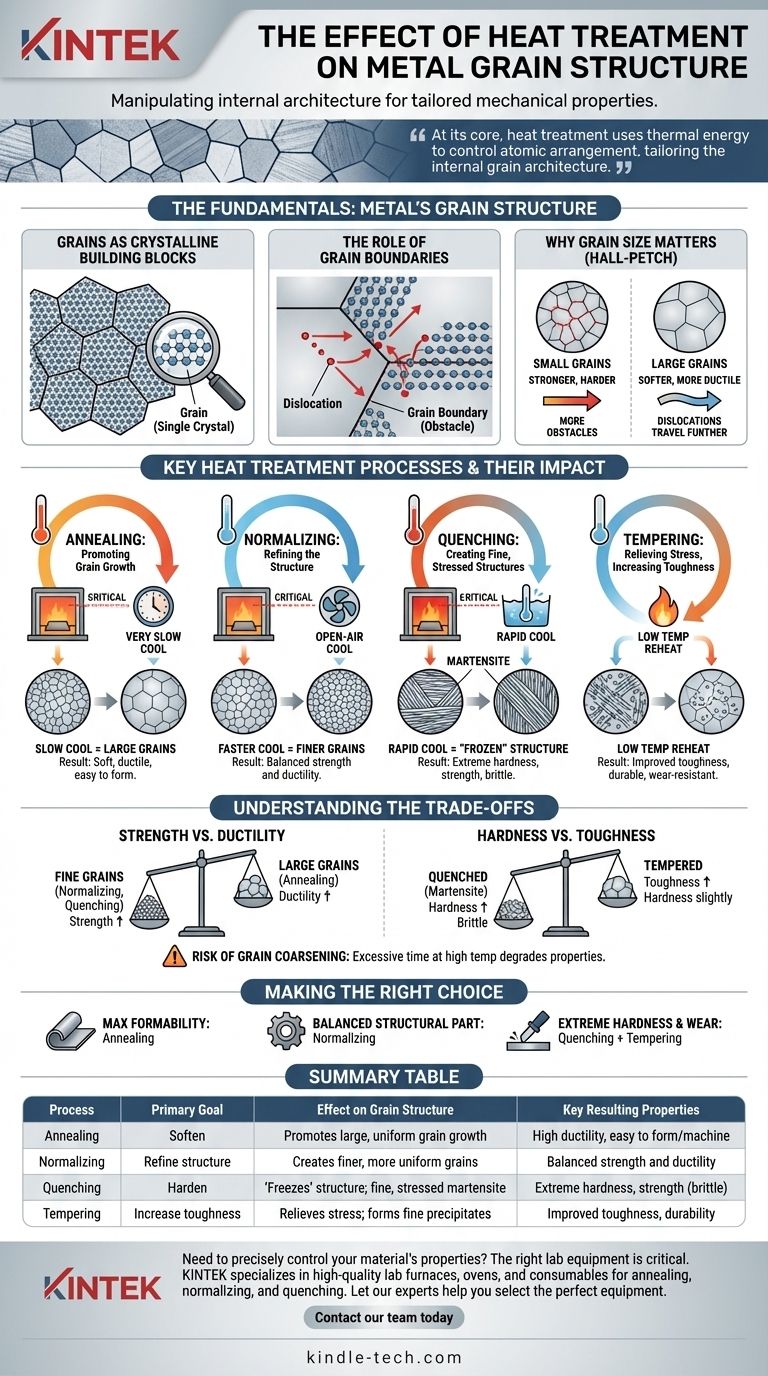

At its core, heat treatment is the primary method metallurgists use to deliberately manipulate a metal's internal grain structure. By precisely controlling heating and cooling cycles, you can change the size, shape, and distribution of these crystalline grains, which directly dictates the material's final mechanical properties like strength, hardness, and ductility.

The fundamental relationship to understand is this: Heat treatment is not just about making a metal hot or cold. It's about using thermal energy to control the atomic arrangement within the material, allowing you to tailor its internal grain architecture to meet specific engineering demands.

The Fundamentals: What is a Metal's Grain Structure?

Grains as Crystalline Building Blocks

Metals are crystalline solids, meaning their atoms are arranged in a highly ordered, repeating lattice. A grain is a single crystal within the metal. Think of a solid piece of steel not as a uniform block, but as a tightly packed mosaic of countless microscopic, individual crystals.

The Role of Grain Boundaries

Where one grain stops and another begins, there is a grain boundary. These boundaries are regions of atomic mismatch and higher energy. Critically, grain boundaries act as obstacles that impede the movement of defects called dislocations.

Since the movement of dislocations is how a metal deforms plastically (permanently bends), more obstacles mean it takes more force to cause deformation.

Why Grain Size Matters

This leads to the most important principle: grain size determines strength.

A material with small grains has a much larger total area of grain boundaries. This creates more obstacles for dislocation movement, making the material stronger and harder. This is known as the Hall-Petch relationship.

Conversely, a material with large grains has fewer boundaries. Dislocations can travel further before being stopped, making the material softer and more ductile (easier to bend and form).

Key Heat Treatment Processes and Their Impact on Grains

Heat treatments use temperature to either encourage the growth of new, stress-free grains or to lock the atomic structure into a highly stressed, fine-grained state.

Annealing: Promoting Grain Growth

Annealing involves heating a metal above its recrystallization temperature and then cooling it very slowly. This process gives atoms ample time and energy to rearrange into a low-stress configuration.

The result is a structure of large, uniform (equiaxed) grains. This makes the material significantly softer, more ductile, and easier to machine or form.

Normalizing: Refining the Grain Structure

Normalizing is similar to annealing but uses a faster cooling rate, typically by letting the part cool in open air. This provides less time for grain growth compared to the slow furnace cooling of annealing.

The process produces a finer, more uniform grain structure than annealing. This results in a material that is stronger and slightly harder than an annealed part, offering a good balance of strength and ductility.

Quenching: Creating Fine, Stressed Structures

Quenching is the process of cooling a metal extremely rapidly from a high temperature, often by submerging it in water, oil, or brine. This "freezes" the atomic structure in a non-equilibrium state.

For steel, this traps carbon atoms in a distorted lattice called martensite. This structure is not defined by traditional grains but by extremely fine "laths" or "plates," creating an immense number of internal boundaries and stresses. The result is a material of extreme hardness and strength, but also very low toughness (brittleness).

Tempering: Relieving Stress and Increasing Toughness

A quenched part is almost always too brittle for practical use. Tempering is a subsequent low-temperature heat treatment that relieves the internal stresses created during quenching.

It allows some controlled atomic rearrangement, transforming the brittle martensite into a microstructure with fine carbide precipitates. This process reduces hardness slightly but dramatically increases toughness, creating a durable and wear-resistant final part.

Understanding the Trade-offs

You cannot optimize every property simultaneously. Heat treatment forces you to make strategic compromises based on the application's needs.

The Strength vs. Ductility Dilemma

This is the most fundamental trade-off. Processes that create fine grains (like normalizing and quenching) increase strength at the expense of ductility. Processes that create large grains (like annealing) increase ductility at the expense of strength.

Hardness vs. Toughness

Quenching produces a material with maximum hardness but minimal toughness, meaning it will shatter rather than bend under impact. Tempering is the act of trading some of that peak hardness to regain the essential property of toughness. The higher the tempering temperature, the more hardness you sacrifice for a greater gain in toughness.

The Risk of Grain Coarsening

Leaving a metal at a high temperature for too long can cause excessive grain growth. This condition, known as grain coarsening, can permanently degrade mechanical properties, making the material weaker and sometimes more susceptible to brittle fracture, even after subsequent heat treatments.

Making the Right Choice for Your Goal

Your choice of heat treatment must be directly linked to the desired performance of the final component.

- If your primary focus is maximum formability and ductility: Annealing is the best choice to create a soft, low-stress material with large grains that is easy to work with.

- If your primary focus is a good balance of strength and toughness for a structural part: Normalizing provides a refined grain structure that delivers superior mechanical properties compared to an as-rolled or annealed state.

- If your primary focus is extreme hardness and wear resistance: Quenching followed by a carefully selected tempering cycle is the required path to achieve a tough, hard, and durable component.

By mastering the principles of heat treatment, you gain direct control over a material's internal architecture and its ultimate performance.

Summary Table:

| Heat Treatment Process | Primary Goal | Effect on Grain Structure | Key Resulting Properties |

|---|---|---|---|

| Annealing | Soften the metal | Promotes large, uniform grain growth | High ductility, easy to form/machine |

| Normalizing | Refine structure | Creates finer, more uniform grains | Balanced strength and ductility |

| Quenching | Harden the metal | 'Freezes' structure; creates fine, stressed martensite | Extreme hardness and strength (but brittle) |

| Tempering | Increase toughness | Relieves stress from quenching; forms fine carbide precipitates | Improved toughness and durability |

Need to precisely control your material's properties? The right lab equipment is critical for successful heat treatment research and development. KINTEK specializes in high-quality lab furnaces, ovens, and consumables that deliver the precise temperature control and uniform heating required for annealing, normalizing, and quenching processes. Let our experts help you select the perfect equipment to achieve your material science goals. Contact our team today to discuss your laboratory's needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Laboratory High Pressure Vacuum Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is a sputtering system? Achieve Unmatched Thin Film Deposition for Your Lab

- What are some common drying methods used in laboratories and their drawbacks? Choose the Right Method to Protect Your Samples

- What is the delta 20 rule of evaporation? Master Safe and Effective Spraying

- What are the precautions that must be observed to ensure accuracy when determining melting point? Master Precise Sample Analysis

- What is the highest temperature of a furnace? Unlocking the Limits of Extreme Heat

- What are the applications of additive manufacturing in dentistry? Unlock Faster, More Precise Patient Care

- What is the difference between biomass and biomass energy? Unlock the Power of Renewable Resources

- What is plasma magnetron sputtering? A Guide to High-Performance Thin-Film Deposition