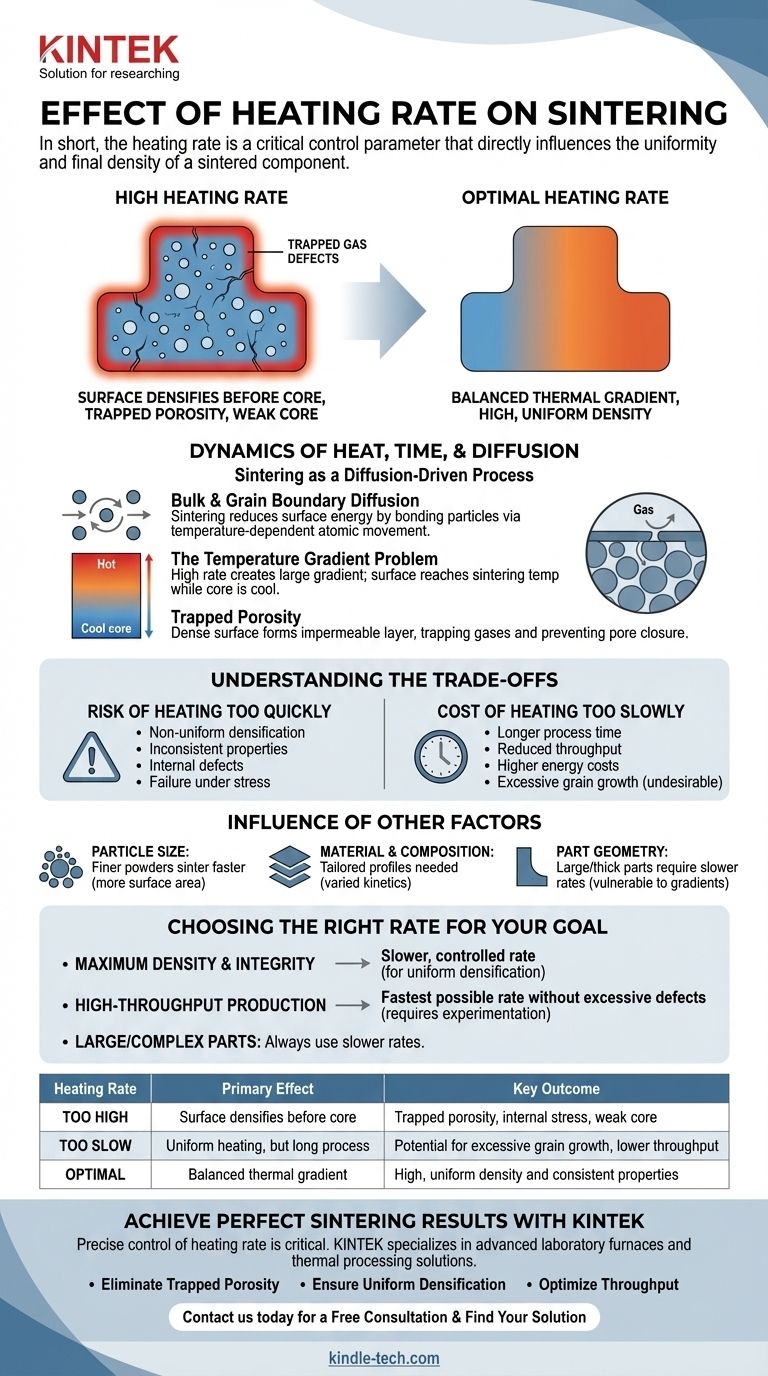

In short, the heating rate is a critical control parameter that directly influences the uniformity and final density of a sintered component. A heating rate that is too high causes the exterior of the part to densify and seal off before the interior has had sufficient time to sinter, leading to trapped porosity, internal stress, and significant variations in material properties.

The central challenge is managing the temperature gradient between the component's surface and its core. An optimal heating rate ensures the entire part heats uniformly, allowing sufficient time for diffusion mechanisms to eliminate porosity before the surface structure fully consolidates.

The Dynamics of Heat, Time, and Diffusion

Sintering is not an instantaneous event that occurs upon reaching a target temperature. It is a kinetic process driven by atomic movement, which requires both sufficient thermal energy and time.

Sintering as a Diffusion-Driven Process

The goal of sintering is to reduce the surface energy of a powder compact by bonding particles and eliminating the pores between them. This happens through material transport mechanisms like bulk diffusion and grain boundary diffusion.

These diffusion processes are heavily dependent on temperature. As temperature rises, atoms become more mobile and can move to fill in pores and form strong bonds between particles.

The Temperature Gradient Problem

When a part is heated, the surface always heats faster than the core. A high heating rate exacerbates this difference, creating a significant temperature gradient.

The surface may reach the optimal sintering temperature while the core is still relatively cool. This causes the outer shell of the component to rapidly densify and shrink.

Trapped Porosity: The Primary Consequence

As the surface densifies, it can form a nearly impermeable layer. This layer effectively traps the porosity within the core of the component.

Gases inside these pores cannot escape, and the diffusion pathways needed to close the pores are cut off. The result is a part with a dense exterior but a porous, weak interior. This directly explains why a high heating rate results in "insufficient sintering degree inside the blank."

Understanding the Trade-offs

Selecting a heating rate is a balancing act between process efficiency and final part quality. There is no single "best" rate; it depends entirely on the material, the part's geometry, and the desired outcome.

The Risk of Heating Too Quickly

The primary risk is non-uniform densification. This leads to a component with inconsistent mechanical properties, reduced overall strength, and a high likelihood of internal defects that can cause failure under stress.

The Cost of Heating Too Slowly

While a slow heating rate is generally safer for achieving uniformity, it is not without drawbacks. The most obvious is a longer total process time, which reduces throughput and increases energy costs.

Furthermore, spending too much time at elevated temperatures can lead to undesirable grain growth. In many materials, smaller grain sizes are crucial for achieving high strength and toughness.

The Influence of Other Factors

The heating rate does not act in isolation. Its effect is moderated by several other critical parameters:

- Particle Size: Finer powders have a higher surface area and sinter more readily at lower temperatures, often allowing for faster heating rates.

- Material & Composition: Different materials have different diffusion kinetics and thermal conductivity, requiring tailored heating profiles.

- Part Geometry: Large or thick parts are far more susceptible to severe temperature gradients and require slower, more conservative heating rates.

Choosing the Right Heating Rate for Your Goal

Your choice of heating rate should be a deliberate decision based on your primary objective for the sintered component.

- If your primary focus is maximum density and structural integrity: Use a slower, more controlled heating rate to minimize thermal gradients and ensure uniform densification throughout the part.

- If your primary focus is high-throughput production: Your goal is to find the fastest possible heating rate that does not introduce unacceptable levels of internal porosity, which requires careful experimentation and process validation.

- If you are working with large or complex-shaped parts: Always err on the side of caution with a slower heating rate, as these geometries are the most vulnerable to the damaging effects of thermal gradients.

Ultimately, mastering the heating rate is about controlling the thermal journey of your material to achieve a predictable and reliable outcome.

Summary Table:

| Heating Rate | Primary Effect on Sintering | Key Outcome |

|---|---|---|

| Too High | Surface densifies before core | Trapped porosity, internal stress, weak core |

| Too Slow | Uniform heating, but long process time | Potential for excessive grain growth, lower throughput |

| Optimal | Balanced thermal gradient and diffusion time | High, uniform density and consistent properties |

Achieve Perfect Sintering Results with KINTEK

Struggling with inconsistent density or internal defects in your sintered components? The precise control of your heating rate is critical. KINTEK specializes in advanced laboratory furnaces and thermal processing solutions designed for maximum control and repeatability.

Our equipment helps researchers and production engineers like you:

- Eliminate Trapped Porosity with precise, programmable heating profiles.

- Ensure Uniform Densification across large or complex parts.

- Optimize Throughput without sacrificing final part quality.

Contact us today to discuss your specific material and geometry requirements. Let our experts help you select the ideal sintering furnace to achieve reliable, high-quality results.

Get a Free Consultation & Find Your Solution

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Mesh belt controlled atmosphere furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is sintering with ceramic materials? The Key to High-Performance Ceramics

- What is the density of ceramic properties? A Guide to Material Selection for High-Performance Applications

- What are the different types of ceramic sintering process? A Guide to Solid-State, Liquid-Phase & Viscous Sintering

- What are the functions of spring-loaded alumina ceramic rods? Ensure Data Purity in Electrode Test Assemblies

- What does ceramic fiber do? Achieve Superior High-Temperature Insulation and Control

- What is porcelain powder used for? From Dental Crowns to Fine China

- How long does ceramic last? Maximize Your Coating's Lifespan & Protection

- What is the strongest zirconia phase? Tetragonal Zirconia Offers Unmatched Toughness