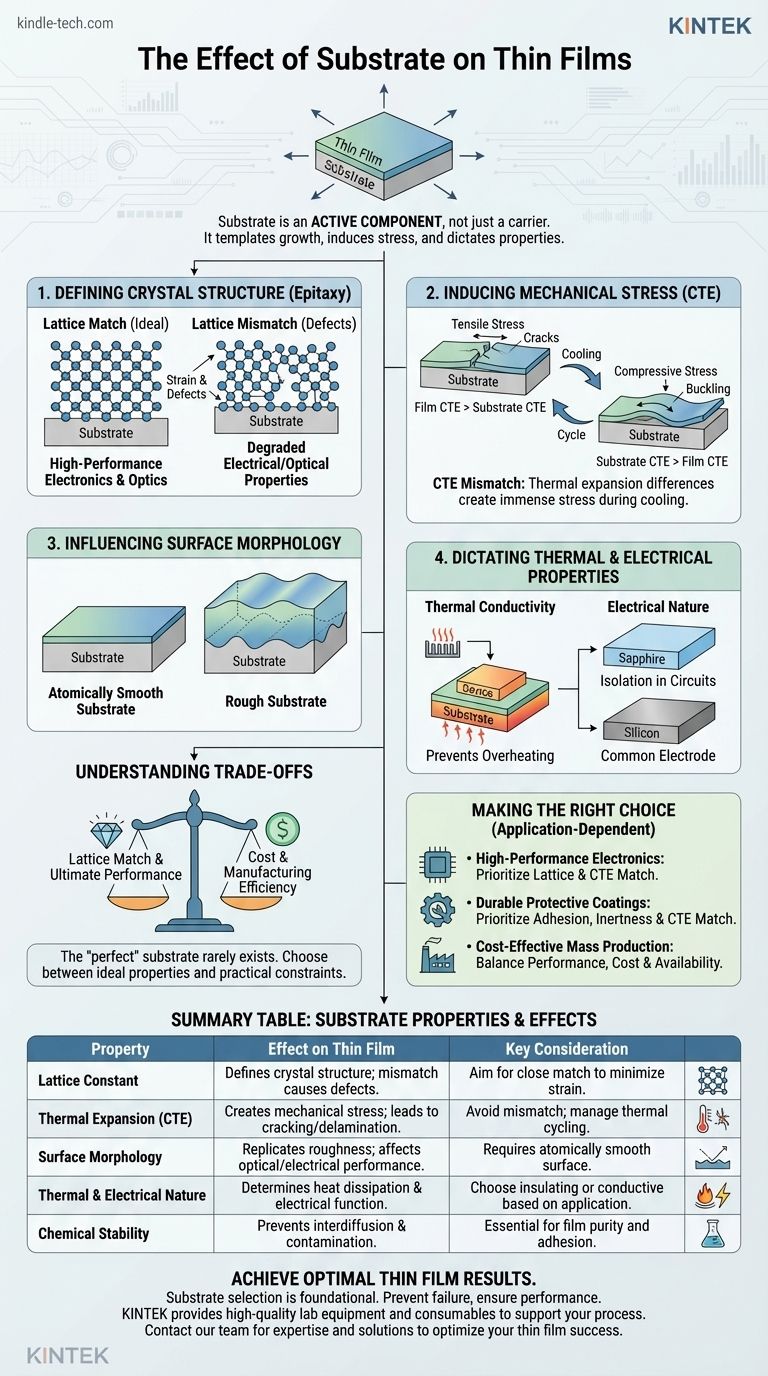

In thin film technology, the substrate is not a passive carrier but an active and critical component that fundamentally dictates the final film's structure, properties, and performance. Its influence extends from the atomic level, defining the crystalline quality of the film, to the macroscopic level, where it can introduce mechanical stress that leads to device failure. The choice of substrate is a foundational engineering decision that can determine the success or failure of the entire fabrication process.

The most critical takeaway is this: a thin film does not exist in isolation. The substrate actively templates the film's growth, induces stress, and contributes to its overall thermal and electrical behavior, making substrate selection as important as the film material itself.

The Substrate's Role: More Than Just a Foundation

Thinking of the substrate as mere physical support is a common oversimplification. In reality, it is an active participant in the film's creation, with its properties directly influencing the final product's quality and functionality.

Defining the Film's Crystal Structure

The arrangement of atoms in the substrate serves as a blueprint for the film growing on top of it, a phenomenon known as epitaxy.

When the atomic spacing of the substrate (lattice constant) closely matches that of the film material, the film can grow with a highly ordered, single-crystal structure. This is the ideal scenario for high-performance electronic and optical devices.

If there is a significant lattice mismatch, the film is forced to stretch or compress to conform to the substrate. This stored energy, or strain, is eventually relieved by creating defects like dislocations, which severely degrade the film's electrical and optical properties.

Inducing Mechanical Stress

Most thin film deposition processes occur at elevated temperatures. As the system cools, the film and substrate contract at different rates according to their unique coefficients of thermal expansion (CTE).

A mismatch in CTE creates immense mechanical stress. If the film contracts more than the substrate, it experiences tensile stress, which can lead to cracking. If the substrate contracts more, the film is put under compressive stress, which can cause it to buckle or delaminate.

Influencing Surface Morphology

The initial surface of the substrate sets the stage for the film's final texture. Any pre-existing roughness, waviness, or contamination on the substrate will be replicated or even amplified in the growing film.

For applications like mirrors or semiconductor wafers, an atomically smooth substrate is non-negotiable. A rough substrate leads to a rough film, causing issues like light scattering in optical coatings or short-circuiting in electronic devices.

Dictating Thermal and Electrical Properties

The substrate is an integral part of the final device's operational environment. Its thermal conductivity determines how effectively heat generated during operation can be dissipated. A poorly chosen substrate can lead to overheating and premature device failure.

Furthermore, the substrate's electrical nature is fundamental. An insulating substrate (like sapphire or quartz) is used to isolate different components in a circuit, while a conductive substrate (like a silicon wafer) can serve as a common electrode.

Understanding the Trade-offs in Substrate Selection

The "perfect" substrate rarely exists. The selection process is a careful balancing act between ideal physical properties and real-world manufacturing constraints like cost and availability.

The Lattice Match vs. Cost Dilemma

A substrate with a near-perfect lattice match for a specific film may be exceptionally effective but also prohibitively expensive or difficult to manufacture. For example, growing gallium nitride (GaN) on a pure GaN substrate is ideal but costly.

Consequently, engineers often compromise by using a less-ideal but far cheaper substrate, such as silicon or sapphire, and then developing complex buffer layers to manage the resulting strain and defects. This is a core trade-off between ultimate performance and manufacturing efficiency.

Thermal Compatibility vs. Functionality

You may find a substrate with an excellent CTE match, minimizing thermal stress. However, that same substrate might have the wrong electrical properties (e.g., being conductive when you need an insulator) or be chemically reactive with your film material at high temperatures.

Chemical Reactivity and Interdiffusion

At the high temperatures used in many deposition techniques, atoms are highly mobile. It is possible for atoms from the substrate to diffuse into the thin film, or vice-versa, creating an unintended interfacial layer.

This interdiffusion can contaminate the film, alter its properties, and create a weak boundary that is prone to adhesion failure. Substrate choice must therefore account for chemical stability at the intended processing temperatures.

Making the Right Choice for Your Application

Selecting the correct substrate requires you to first define your primary goal. The optimal choice is always context-dependent.

- If your primary focus is high-performance electronics or optics: Prioritize a substrate with the closest possible lattice match and thermal expansion coefficient to grow a low-defect, single-crystal film.

- If your primary focus is durable protective coatings: Prioritize strong adhesion, chemical inertness, and a CTE match that prevents cracking or delamination under thermal cycling.

- If your primary focus is cost-effective mass production: Identify a substrate that offers an acceptable balance of performance, cost, and availability, and be prepared to engineer solutions to mitigate its physical shortcomings.

Treating the substrate as an integral component of your design, not just a carrier, is the key to predictable and successful thin film engineering.

Summary Table:

| Substrate Property | Effect on Thin Film | Key Consideration |

|---|---|---|

| Lattice Constant | Defines crystal structure via epitaxy; mismatch causes defects. | Aim for close match to minimize strain and dislocations. |

| Thermal Expansion (CTE) | Creates mechanical stress (tensile/compressive) during cooling. | Mismatch can lead to cracking, buckling, or delamination. |

| Surface Morphology | Replicates roughness, affecting optical and electrical performance. | Requires atomically smooth surface for high-quality films. |

| Thermal & Electrical Nature | Determines heat dissipation and electrical isolation/connection. | Choose insulating (e.g., sapphire) or conductive (e.g., silicon) based on application. |

| Chemical Stability | Prevents interdiffusion and contamination at high temperatures. | Essential for maintaining film purity and strong adhesion. |

Achieve Optimal Thin Film Results with the Right Substrate

Substrate selection is a foundational decision that directly impacts the quality, performance, and reliability of your thin film devices. The right choice prevents issues like stress-induced failure, poor crystallinity, and contamination.

KINTEK specializes in providing high-quality laboratory equipment and consumables to support your entire thin film fabrication process. Whether you are developing high-performance electronics, durable coatings, or cost-effective mass-produced components, we offer solutions to meet your specific substrate and processing needs.

Let our expertise guide you to success. Contact our team today to discuss your application requirements and discover how we can help you select the ideal substrate and optimize your thin film processes for superior results.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the purpose of ITO coating? Enabling Transparent Electronics for Modern Devices

- Is carbon nanotube an electrical conductor? Its dual nature depends on atomic structure.

- What is the purpose of thin film deposition? Enhance Surface Properties for Superior Performance

- What are the applications of carbon nanotubes in biotechnology? Unlock Targeted Drug Delivery & Advanced Biosensing

- How do you make plasma in sputtering? Master the Recipe for Efficient Thin-Film Deposition

- What is the thickness of a film? A Guide to the 1mm Threshold and Measurement Units

- What are the practical uses of thin film interference? Control Light for Optics, Security & Manufacturing

- What are the advantages of ion beam sputtering? Achieve Superior Thin Film Quality and Precision