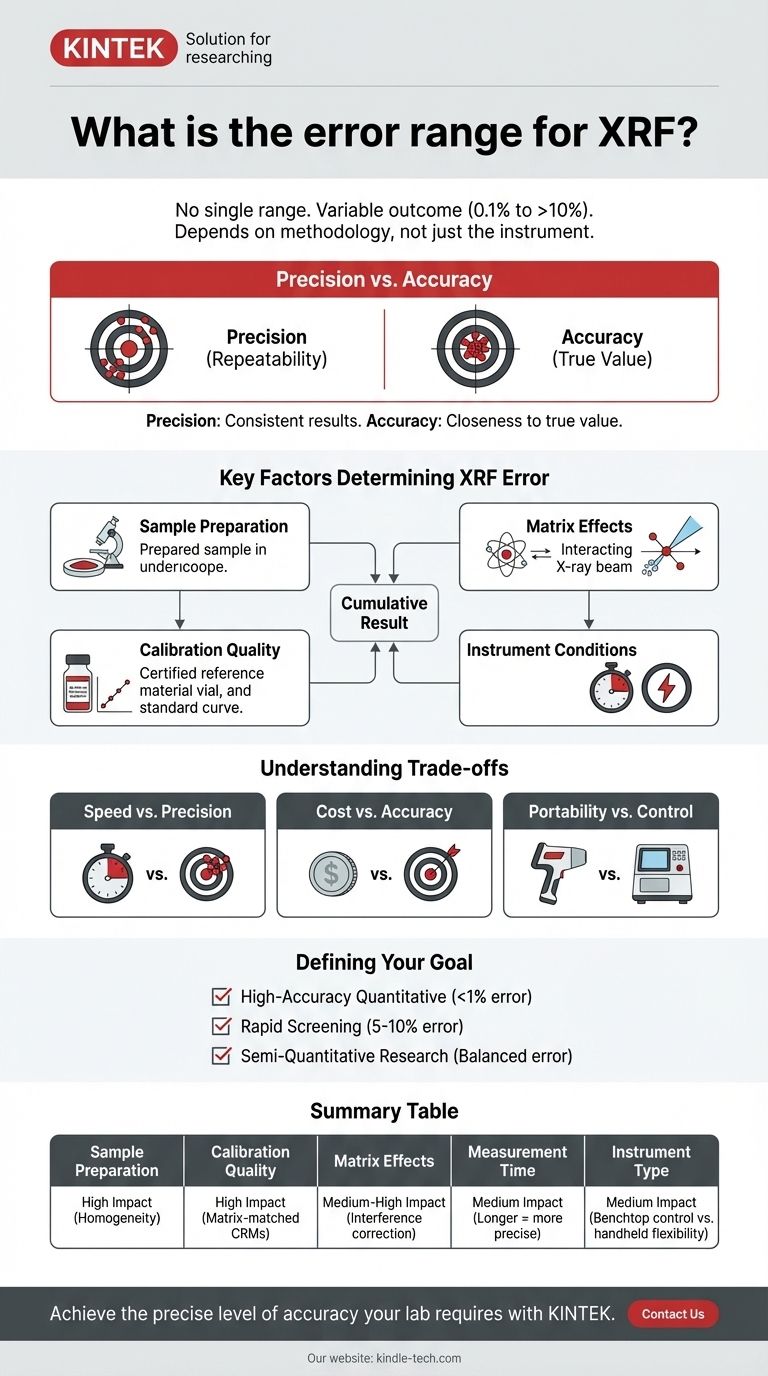

There is no single error range for X-Ray Fluorescence (XRF) analysis. The accuracy of an XRF measurement is not a fixed number but a variable outcome, with typical relative errors ranging from as low as 0.1% for ideal samples to over 10% for unprepared or complex materials. This variability is not a flaw in the technique but a direct consequence of the sample itself and the rigor of the analytical method employed.

The critical takeaway is that XRF error is not an inherent specification of the instrument but a direct result of your entire analytical methodology. You have a significant degree of control over the quality of your results by managing sample preparation, calibration, and measurement conditions.

The Two Pillars of Measurement Error: Precision vs. Accuracy

To understand error in XRF, you must first distinguish between precision and accuracy. They are not interchangeable terms.

What is Precision?

Precision refers to the repeatability of a measurement. If you analyze the same sample ten times and get very similar results each time, your method is precise.

This is a measure of random statistical error. The results are clustered tightly together, but they are not necessarily close to the true value.

What is Accuracy?

Accuracy refers to the closeness of a measurement to the true, accepted value. If a certified standard contains 15.0% chromium and your XRF result is 14.9%, your measurement is highly accurate.

Accuracy is affected by systematic errors, such as a flawed calibration or uncorrected interferences. You can be precise without being accurate, which is a common and dangerous pitfall.

Why This Distinction Matters for XRF

An XRF instrument can be highly precise, consistently reporting the same wrong number due to a poor calibration. Your goal is to achieve both high precision and high accuracy, which requires controlling the key sources of systematic error.

Key Factors That Determine XRF Error

The final error of your measurement is a cumulative result of several factors. Mastering them is the key to reliable data.

Sample Preparation: The Foundation of Quality

This is the single most important factor influencing XRF accuracy. The X-rays analyze a very thin surface layer, so what it sees must represent the entire sample.

Key preparation factors include homogeneity (is the sample uniform?), surface finish (is it flat and smooth?), and particle size. Inconsistent preparation is the largest source of error in most real-world applications.

Matrix Effects: The Physics of Interference

The "matrix" is everything in the sample other than the specific element you're measuring. Elements within the sample can absorb or enhance the X-ray signals of other elements.

For example, iron can absorb the signal from nickel, making the instrument report a lower nickel concentration than is actually present. This is a matrix effect, and it must be corrected through proper calibration to achieve accuracy.

Calibration Quality: Teaching the Machine

An XRF instrument doesn't inherently know what 10% copper looks like. You must teach it by running a calibration with Certified Reference Materials (CRMs).

The accuracy of your analysis is fundamentally limited by the quality of your calibration. Using CRMs that closely match the matrix of your unknown samples is the most effective way to correct for matrix effects and ensure high accuracy.

Instrument Conditions: Counting Time and Power

Longer measurement times allow the detector to collect more X-ray counts, which reduces random statistical error and improves precision.

Higher power can also improve signals for certain elements. Optimizing these settings for your specific application is a crucial step in developing a robust method.

Understanding the Trade-offs

Choosing an XRF methodology involves balancing competing priorities.

Speed vs. Precision

A 10-second "screening" analysis will always be less precise than a 300-second quantitative analysis. You must decide if you need a quick sort or a highly reliable number.

Cost vs. Accuracy

The highest accuracy requires matrix-matched Certified Reference Materials, which can be expensive. A less accurate analysis might rely on a generic, "fundamental parameters" calibration that requires few or no standards but is more susceptible to matrix-effect errors.

Portability vs. Control

Handheld XRF (pXRF) analyzers offer incredible flexibility in the field. However, they are more susceptible to errors from variable sample positioning and environmental conditions compared to high-power, laboratory-based benchtop systems.

How to Define an Acceptable Error Range for Your Goal

The "right" amount of error depends entirely on your objective. Use your goal to guide your methodology.

- If your primary focus is high-accuracy quantitative analysis (e.g., alloy QC): Your goal is accuracy below 1% relative error, which requires rigorous sample preparation and a suite of matrix-matched CRMs.

- If your primary focus is rapid screening or sorting (e.g., scrap metal): Your goal is precision to differentiate materials, where an error of 5-10% might be perfectly acceptable as long as it's consistent.

- If your primary focus is semi-quantitative research (e.g., geology, archaeology): Your goal is a balance, where careful sample preparation is critical but a wider-ranging calibration may be used to identify trends and elemental ratios.

By understanding these factors, you transform the question from "What is the error?" to "How do I achieve the level of accuracy I need?"

Summary Table:

| Factor | Impact on Error | Key Consideration |

|---|---|---|

| Sample Preparation | High | Homogeneity, surface finish, and particle size are critical for accuracy. |

| Calibration Quality | High | Matrix-matched Certified Reference Materials (CRMs) minimize systematic error. |

| Matrix Effects | Medium-High | Elemental interferences (absorption/enhancement) must be corrected. |

| Measurement Time | Medium | Longer counting times improve precision by reducing statistical noise. |

| Instrument Type | Medium | Benchtop systems offer more control than handheld for complex matrices. |

Achieve the precise level of accuracy your lab requires. The right equipment and methodology are critical for reliable XRF results. KINTEK specializes in lab equipment and consumables, serving laboratory needs with high-performance XRF systems, sample preparation tools, and calibration standards. Let our experts help you design a method that delivers the confidence you need.

Contact our analytical specialists today for a personalized consultation.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Electrolytic Electrochemical Cell for Coating Evaluation

- Evaporation Crucible for Organic Matter

People Also Ask

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What role do laboratory autoclaves play in pectin extraction? Optimize Prebiotic Yield from Citrus and Apple Biomass

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam