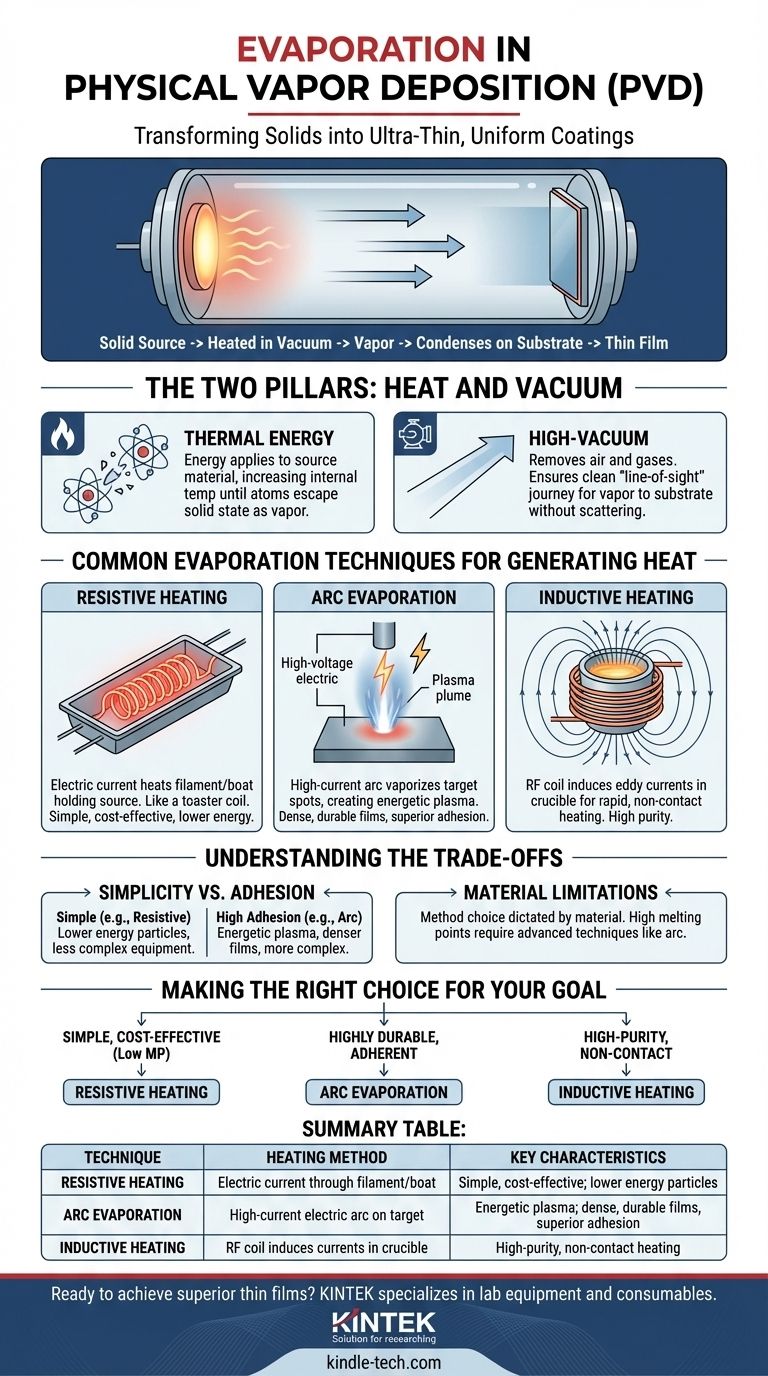

In Physical Vapor Deposition (PVD), the evaporation method is a process where a solid source material is heated within a high-vacuum chamber until it transforms into a vapor. This vapor then travels through the vacuum and condenses onto a cooler target object, known as a substrate, forming an ultra-thin, uniform coating.

The core principle of PVD by evaporation is straightforward: convert a solid material into a gas using heat, and then let that gas re-solidify as a thin film onto a surface. The key is controlling the heating method and maintaining a vacuum to ensure the vapor travels without interference.

The Two Pillars of Evaporation: Heat and Vacuum

To understand how this process works, it's essential to grasp the two fundamental components that make it possible: the application of thermal energy and the environment in which it occurs.

The Role of Thermal Energy

The entire process begins by applying energy—typically heat—to a source material. This energy increases the material's internal temperature to the point where its atoms gain enough momentum to break their bonds and escape the solid state, turning directly into a gas or vapor. The specific method used to generate this heat defines the different types of evaporation techniques.

Why a Vacuum is Non-Negotiable

The process must occur in a high-vacuum environment. This vacuum removes air and other gas molecules from the chamber, serving a critical purpose. Without a vacuum, the evaporated material atoms would constantly collide with air molecules, scattering them and preventing them from reaching the substrate in a straight, unimpeded path. The vacuum ensures a clean "line-of-sight" journey from the source to the substrate, which is essential for forming a high-quality, uniform film.

Common Techniques for Generating Heat

While the principle is the same, the method used to heat and vaporize the source material varies. This choice impacts the energy of the vapor and the properties of the final film.

Resistive Heating (Thermal Evaporation)

This is one of the most direct methods. A resistive heat source, like a super-heated filament or a ceramic "boat," holds the source material. An electric current is passed through the source, causing it to heat up and evaporate, much like how a toaster coil glows red hot.

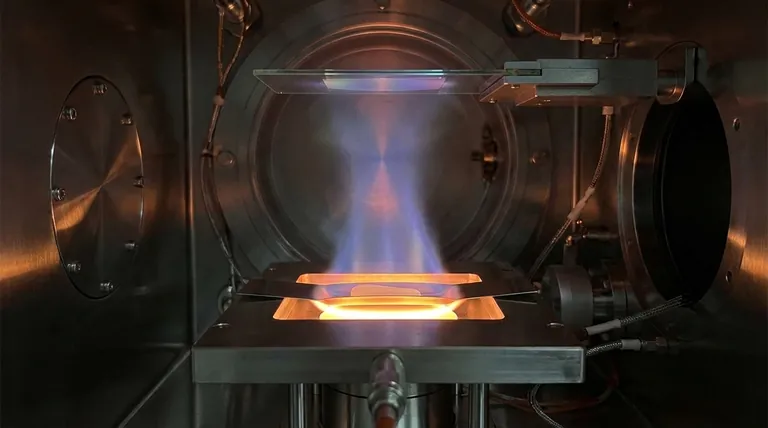

Arc Evaporation

This is a more energetic technique. A high-current, low-voltage electric arc is struck on the surface of the solid source material (the target). The arc's immense energy vaporizes tiny spots on the target, creating a highly ionized plasma of the material. This plasma is then guided to the substrate to form the coating.

Inductive Heating

This method uses electromagnetic induction. A crucible containing the source material is placed inside a coil. A high-frequency alternating current (RF power) is passed through the coil, creating a changing magnetic field. This field induces powerful electrical currents (eddy currents) within the crucible, causing it to heat up rapidly and evaporate the material inside without direct contact.

Understanding the Trade-offs

Each evaporation technique comes with its own set of advantages and limitations. The primary trade-off is often between the simplicity of the process and the quality or energy of the resulting film.

Simplicity vs. Adhesion

Methods like resistive thermal evaporation are relatively simple and cost-effective. However, the evaporated particles have lower kinetic energy. More energetic processes like arc evaporation create an ionized plasma, resulting in a denser and more durable film with superior adhesion to the substrate, but the equipment is more complex.

Material Limitations

The choice of method can also be dictated by the material itself. Some materials have extremely high melting points that are difficult to reach with simple resistive heating, making techniques like arc or electron beam evaporation more suitable.

Making the Right Choice for Your Goal

Selecting the appropriate evaporation method depends entirely on the desired properties of the final thin film and the material being deposited.

- If your primary focus is a simple, cost-effective coating for materials with lower melting points: Standard vacuum thermal evaporation using resistive heating is often the most practical choice.

- If your primary focus is a highly durable, dense, and strongly adhered film: Arc evaporation provides the high-energy plasma needed to achieve superior coating properties.

- If your primary focus is depositing a high-purity film without direct contact from a heating element: Inductive heating offers a clean, contained method for materials that can be heated in a crucible.

Ultimately, understanding these foundational techniques empowers you to select the process that best aligns with your material and performance requirements.

Summary Table:

| Technique | Heating Method | Key Characteristics |

|---|---|---|

| Resistive Heating | Electric current through a filament/boat | Simple, cost-effective; lower energy particles |

| Arc Evaporation | High-current electric arc on target | Energetic plasma; dense, durable films with superior adhesion |

| Inductive Heating | RF coil induces currents in a crucible | High-purity, non-contact heating; suitable for crucible-contained materials |

Ready to achieve superior thin films for your laboratory?

The right PVD evaporation technique is critical for coating performance. KINTEK specializes in lab equipment and consumables, serving all your laboratory needs. Our experts can help you select the ideal evaporation method—whether for cost-effective resistive heating or high-adhesion arc evaporation—to ensure your materials meet their performance requirements.

Contact our team today to discuss your specific application and discover how KINTEK's solutions can enhance your research and development.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is the evaporation process in semiconductors? A Guide to Thin Film Deposition

- What are the drawbacks of thermal evaporation? Understanding the Limitations for High-Performance Applications

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What is thermal evaporation used to deposit? A Guide to Metals, Compounds, and Key Applications

- What is the meaning of thermal evaporation? A Guide to Simple, Cost-Effective Thin Film Coating