The fundamental rule for handling any glass electrolytic cell is to treat it as the fragile scientific instrument it is. All actions, from movement to storage, must be executed with deliberate care and gentleness to prevent breakage and ensure the integrity of your experiments.

The core challenge is not just avoiding catastrophic breaks, but also preserving the cell's condition for future use. Proper handling extends beyond careful movement to include meticulous post-use procedures for drying and storage.

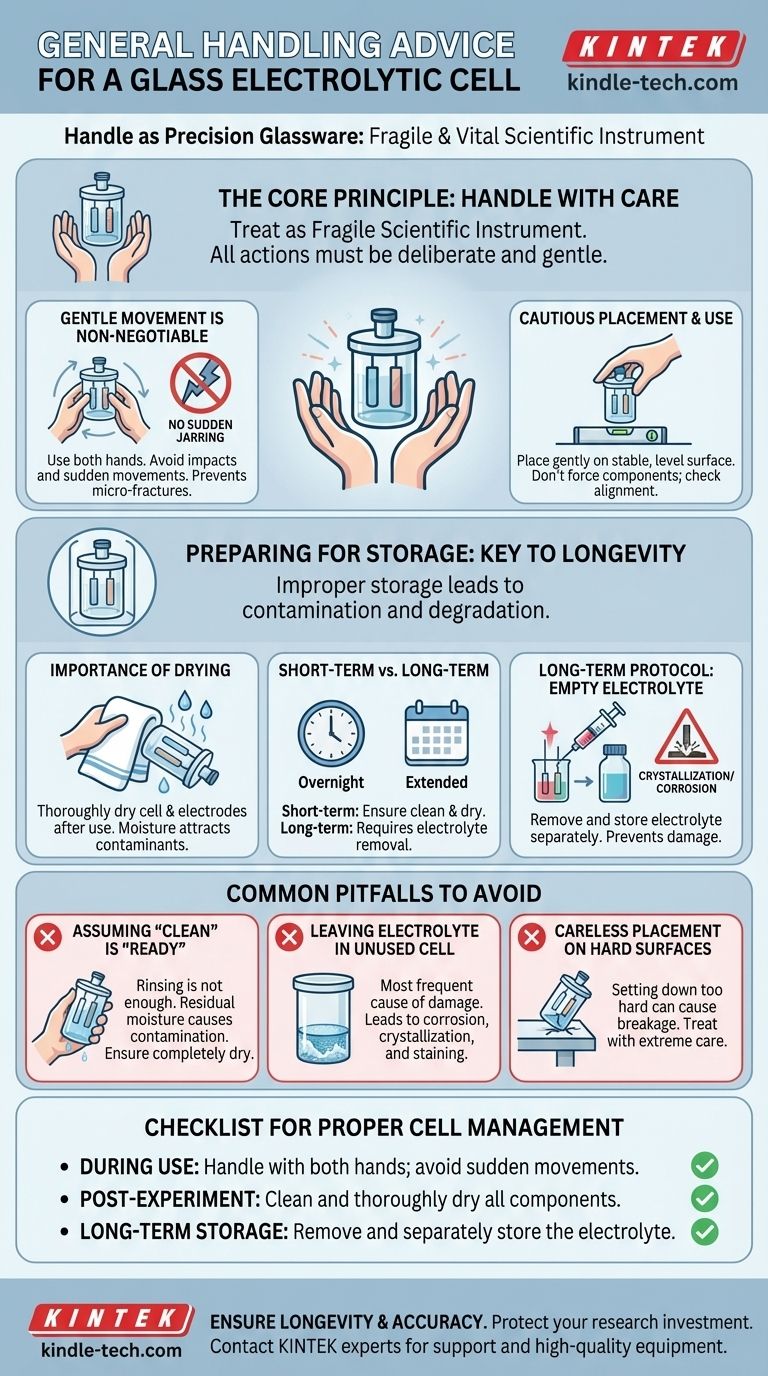

The Core Principle: Handle as Precision Glassware

An electrolytic cell is a piece of scientific apparatus where precision matters. Its physical integrity is directly linked to the quality of the data it helps produce.

Gentle Movement is Non-Negotiable

The cell body and its components are made of glass, making them inherently fragile. Always use both hands when possible, and avoid any sudden, jarring movements.

Impacts, even minor ones, can create micro-fractures that compromise the cell's structural integrity over time, leading to unexpected failure.

Cautious Placement and Use

Always place the cell down gently on a stable, level surface. When assembling or disassembling the cell, handle each glass component with the same level of care.

Never apply excessive force. If components do not fit together smoothly, stop and re-examine the alignment rather than trying to force them.

Preparing for Storage: The Key to Longevity

How you store the cell is as important as how you handle it during an experiment. Improper storage can lead to contamination or degradation.

The Importance of Drying

After use, the cell and its electrodes must be thoroughly dried. Moisture can attract contaminants from the air and may interfere with the results of subsequent experiments.

Store the cleaned and dried components in a dry, dust-free environment to maintain their pristine condition.

Differentiating Short-Term vs. Long-Term Storage

The required storage protocol depends on how long the cell will be out of use.

For short-term storage (e.g., overnight), ensuring the components are clean and dry is sufficient. For long-term storage, you must take an additional, critical step.

Long-Term Protocol: Empty the Electrolyte

If the cell will not be used for an extended period, the electrolyte must be removed completely.

Leaving the electrolyte in the cell can lead to crystallization, corrosion of electrodes, or permanent staining of the glass, all of which can ruin the apparatus. The removed electrolyte should be stored separately in a properly sealed container.

Common Pitfalls to Avoid

Mistakes in handling and storage are common and can be costly, both in terms of equipment replacement and compromised research.

Assuming "Clean" is "Ready"

Simply rinsing the cell is not enough. Residual moisture is a primary source of contamination. Always ensure every component is completely dry before storing it away.

Leaving Electrolyte in an Unused Cell

This is the most frequent cause of long-term damage. The convenience of leaving a cell "ready to go" is far outweighed by the risk of corrosion and crystallization.

Careless Placement on Hard Surfaces

Setting the cell down too hard, even on what appears to be a safe lab bench, can cause it to break. Treat it with the same care you would any other piece of delicate glassware.

A Checklist for Proper Cell Management

Your approach should be tailored to the immediate task, whether you are actively using the cell or preparing it for storage.

- If you are actively using the cell: Handle all glass components with deliberate and gentle movements to prevent impacts or stress.

- If you have just finished an experiment: Ensure the cell and electrodes are thoroughly cleaned and, most importantly, completely dried.

- If you are preparing for long-term storage: Remove and separately store the electrolyte before cleaning, drying, and sealing the cell in a moisture-free environment.

Proper handling is the simplest and most effective way to protect your investment and ensure reliable experimental results.

Summary Table:

| Handling Phase | Critical Action | Why It Matters |

|---|---|---|

| During Use | Handle with both hands; avoid sudden movements. | Prevents micro-fractures and catastrophic breaks. |

| Post-Experiment | Clean and thoroughly dry all components. | Eliminates moisture that can cause contamination. |

| Long-Term Storage | Remove and store electrolyte separately. | Prevents crystallization, corrosion, and staining. |

Ensure the longevity and accuracy of your experiments with the right equipment and expert support. KINTEK specializes in high-quality laboratory equipment and consumables, including durable glassware designed for precise applications. Our team can help you select the right tools and provide guidance on best practices for maintenance and handling. Protect your research investment—contact our experts today to discuss your lab's specific needs!

Visual Guide

Related Products

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Electrolytic Electrochemical Cell for Coating Evaluation

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- What are the typical volumes and aperture configurations for a double-layer water-bath electrolytic cell? Optimize Your Electrochemical Setup

- What is a H type cell? A Guide to Divided Electrochemical Cells for Accurate Experiments

- How should the H-type electrolytic cell be stored when not in use? Expert Storage & Maintenance Guide

- What is the overall structure of the H-type double-layer optical water bath electrolytic cell? Precision Design for Controlled Experiments

- What optical features does the H-type electrolytic cell have? Precision Quartz Windows for Photoelectrochemistry