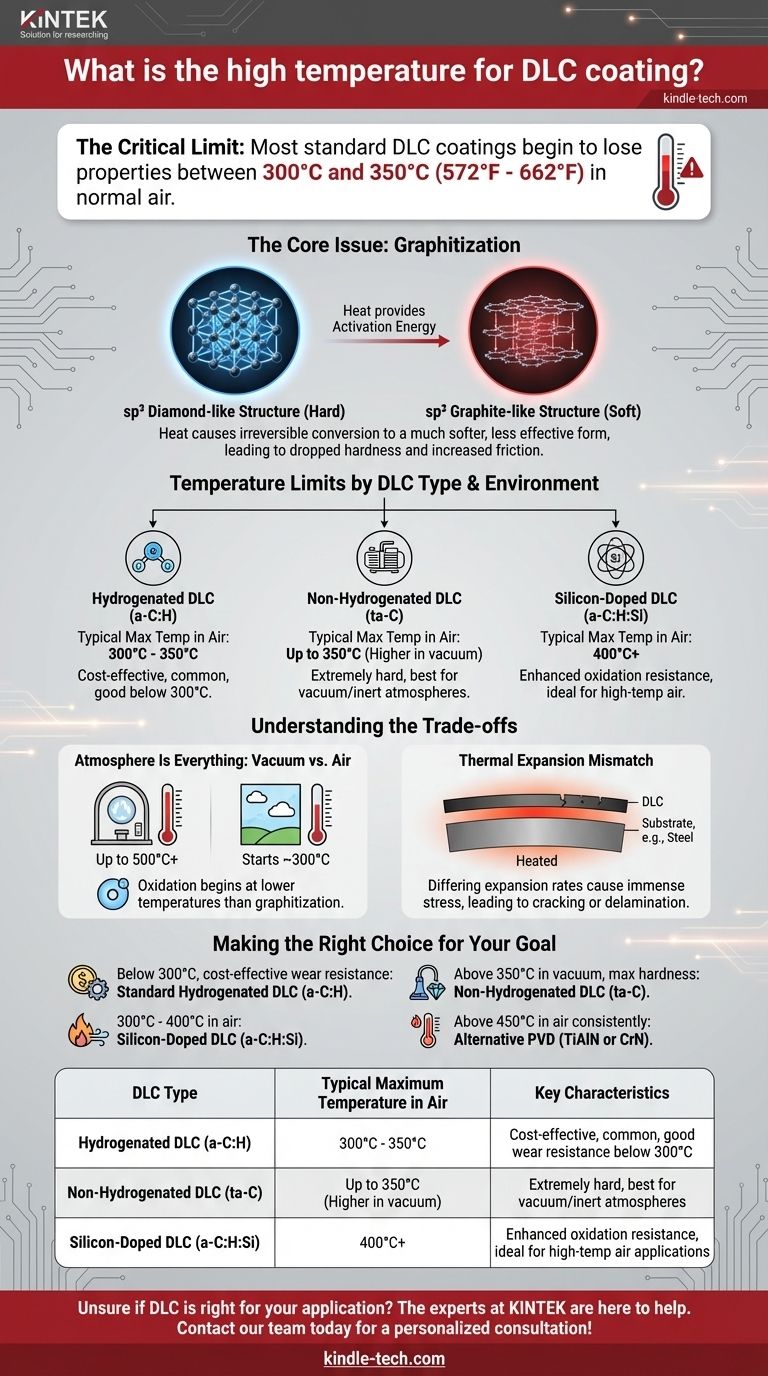

The short answer is that most standard DLC (Diamond-Like Carbon) coatings begin to lose their critical properties between 300°C and 350°C (572°F - 662°F) when operating in a normal air atmosphere. However, this temperature limit is not a single number; it varies significantly based on the specific type of DLC and the operating environment, with some advanced formulations remaining stable at over 500°C in a vacuum.

The core issue is thermal stability. A DLC coating's exceptional hardness and low friction come from its "diamond-like" atomic structure. Heat provides the energy for this structure to break down and convert into a much softer, less effective "graphite-like" form, fundamentally compromising its performance.

Why Temperature Limits DLC Performance

To understand if DLC is right for your application, you must first understand what is happening at an atomic level as the coating gets hot. The entire value of the coating is tied to a specific arrangement of carbon atoms that is vulnerable to heat.

The Foundation: sp³ vs. sp² Carbon Bonds

A DLC coating is a mix of two types of carbon bonds. sp³ bonds are the strong, rigid bonds that give diamonds their extreme hardness. sp² bonds are the planar bonds that allow graphite layers to slide easily, making it a good solid lubricant.

The high percentage of sp³ bonds is what gives a DLC coating its "diamond-like" hardness and wear resistance. The goal is to maximize and preserve this sp³ content.

The Failure Mechanism: Graphitization

The high-energy sp³ diamond structure is metastable, meaning it's stable but not in its lowest possible energy state. The sp² graphite structure is more stable from a thermodynamic perspective.

When you add enough heat, you provide the activation energy for the carbon atoms to re-arrange themselves from the desirable sp³ state into the more stable sp² state. This irreversible conversion process is called graphitization.

The Impact on Key Properties

Once graphitization begins, the coating's performance degrades rapidly.

You will see a significant drop in hardness and wear resistance. At the same time, the coefficient of friction often increases, eliminating the low-friction benefits the coating was chosen for. The coating effectively ceases to be "diamond-like."

Temperature Limits by DLC Type

Not all DLC is created equal. Additives and manufacturing methods create different categories, each with a distinct thermal budget.

Hydrogenated DLC (a-C:H)

This is the most common and cost-effective type of DLC. The hydrogen incorporated into the structure, however, makes it less thermally stable.

These coatings typically begin to degrade around 300°C to 350°C. The presence of hydrogen promotes the conversion to the sp² graphite structure at lower temperatures.

Non-Hydrogenated DLC (ta-C)

Tetrahedral amorphous carbon (ta-C) is created without hydrogen and has a very high percentage of sp³ bonds, making it one of the hardest types of DLC.

Its lack of hydrogen gives it a higher thermal stability. In a vacuum or inert atmosphere, ta-C coatings can be stable up to 550°C or even 600°C.

Doped DLC (e.g., a-C:H:Si or a-C:H:W)

To improve thermal and oxidative resistance, other elements can be added to the DLC matrix. Silicon (Si) is a common and effective dopant.

Silicon-doped DLC (often written as a-C:H:Si) forms a silica (glass-like) passivation layer upon heating in air, which helps protect the underlying carbon structure. This can push the effective operating temperature in air to 400°C or higher. Other metal dopants like tungsten (W) or titanium (Ti) can also modify performance.

Understanding the Trade-offs

The absolute temperature limit is only part of the story. The operational context is just as critical.

Atmosphere Is Everything: Vacuum vs. Air

The temperature limits discussed so far are often cited for performance in a vacuum or inert gas. Operating in normal air introduces oxygen, which creates a new failure mode: oxidation.

Oxidation can begin at temperatures lower than graphitization. This is why a ta-C coating stable to 600°C in a vacuum might fail closer to 350°C in air. The resistance to oxidation, not just thermal breakdown, often becomes the limiting factor.

Thermal Expansion Mismatch

High temperatures cause materials to expand. The DLC coating and the substrate material (e.g., steel, aluminum) will almost certainly expand at different rates.

This mismatch in the coefficient of thermal expansion (CTE) generates immense stress at the interface between the coating and the part. This stress can cause the coating to crack, flake, or delaminate entirely, even if graphitization has not occurred.

Making the Right Choice for Your Goal

Selecting the correct coating requires matching the formulation and its limitations to your specific operating environment.

- If your primary focus is cost-effective wear resistance in applications below 300°C: Standard hydrogenated DLC (a-C:H) is an excellent and widely used choice.

- If your primary focus is performance in air between 300°C and 400°C: A silicon-doped DLC (a-C:H:Si) is the most logical candidate to investigate.

- If your primary focus is maximum hardness and performance in a vacuum above 350°C: A non-hydrogenated tetrahedral amorphous carbon (ta-C) coating is the superior option.

- If your application consistently operates in air above 450°C: DLC is likely the wrong technology, and you should evaluate alternative PVD coatings like Titanium Aluminum Nitride (TiAlN) or Chromium Nitride (CrN).

Ultimately, a successful application depends on a clear understanding of your specific thermal and environmental challenges.

Summary Table:

| DLC Type | Typical Maximum Temperature in Air | Key Characteristics |

|---|---|---|

| Hydrogenated DLC (a-C:H) | 300°C - 350°C | Cost-effective, common, good wear resistance below 300°C |

| Non-Hydrogenated DLC (ta-C) | Up to 350°C (Higher in vacuum) | Extremely hard, best for vacuum/inert atmospheres |

| Silicon-Doped DLC (a-C:H:Si) | 400°C+ | Enhanced oxidation resistance, ideal for high-temp air applications |

Unsure if DLC is right for your high-temperature application? The experts at KINTEK are here to help. We specialize in lab equipment and consumables, including advanced coating solutions. We can help you select the optimal DLC type or alternative coating to ensure peak performance and durability for your specific thermal and environmental challenges. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Graphite Vacuum Continuous Graphitization Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the allowable stress for a quartz tube? Understanding Its Brittle Nature and Practical Limits

- Why is a controlled atmosphere tube furnace required for HPS catalysts? Ensure Optimal Metal Site Activation

- How do high-temperature tube furnaces or rotary furnaces facilitate the regeneration of spent activated carbon?

- What are the advantages of using multi-stage split tube furnaces for heating methane pyrolysis reactors? Boost Efficiency

- How does a three-zone high-temperature split tube furnace ensure data accuracy in creep experiments? Achieve Thermal Precision