In the world of high-performance manufacturing, Hot Isostatic Pressing, or HIP, is a critical post-casting process that uses a combination of high temperature and immense, uniform pressure to eliminate internal defects. By subjecting a cast component to these conditions in an inert gas environment, the process effectively "heals" microscopic voids and porosity within the metal, forcing the material to fuse together on an atomic level.

The core challenge with metal castings is the potential for hidden internal porosity, which can compromise structural integrity. Hot Isostatic Pressing directly solves this by transforming a standard casting into a fully dense, high-performance component with significantly improved strength and reliability.

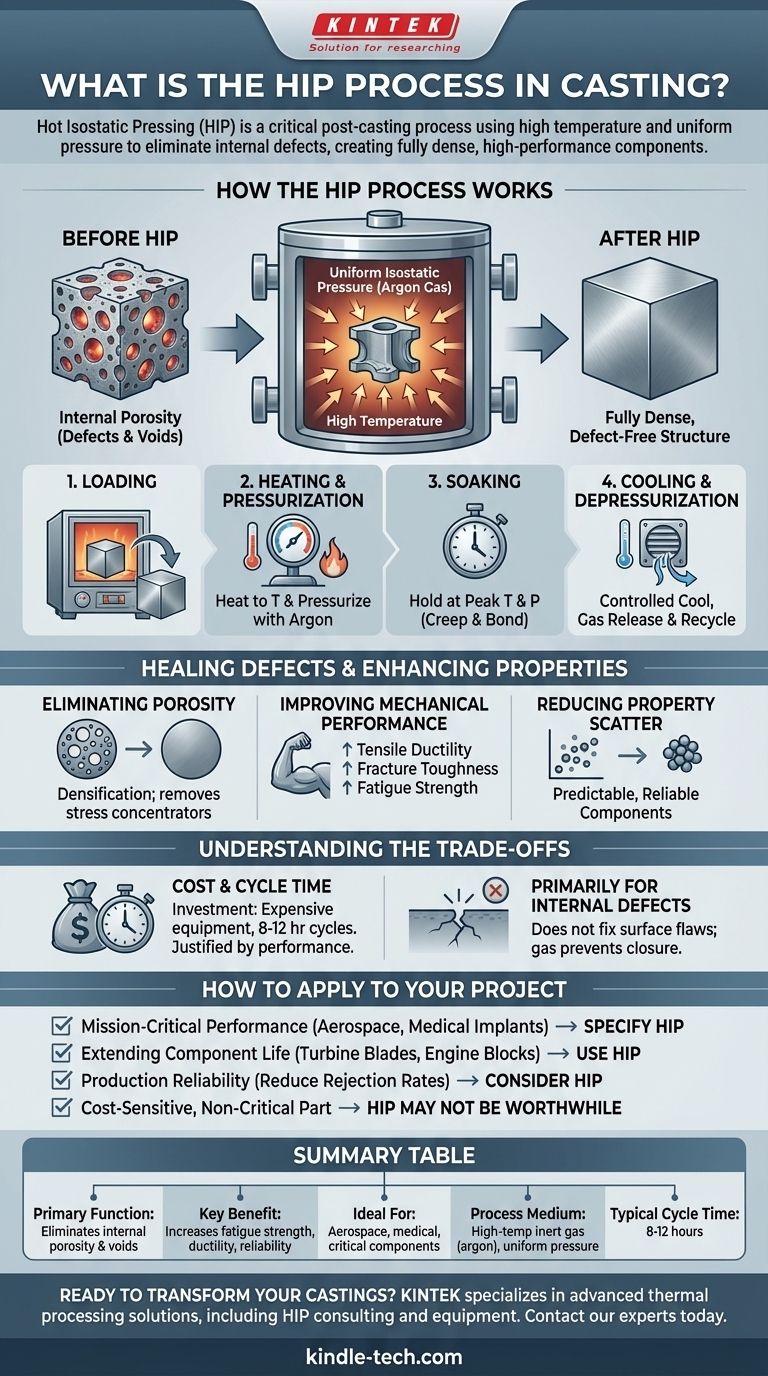

How the HIP Process Works

The HIP process is fundamentally about applying energy—in the form of heat and pressure—to change a material's physical structure for the better. It takes place inside a specialized piece of equipment that is both a furnace and a high-pressure vessel.

The Core Principle: Isostatic Pressure

The key is the term isostatic, which means the pressure is applied uniformly from all directions. This is achieved by using a gas, typically argon, as the pressure medium. At elevated temperatures, the metal becomes malleable enough for this immense, even pressure to collapse and permanently weld shut any internal voids.

The Step-by-Step Breakdown

- Loading: Components are first loaded into the furnace section of the HIP unit.

- Heating and Pressurization: The vessel is sealed, and the furnace heats the parts to a specific temperature, often a significant fraction of the alloy's melting point. Simultaneously, inert argon gas is pumped into the vessel, raising the pressure to extreme levels.

- Soaking: The components are held at this peak temperature and pressure for a specified period, known as the "soak" time. This dwell time, which can last several hours, allows the material to creep and bond across the internal voids.

- Cooling and Depressurization: The components are cooled in a controlled manner. Some modern HIP units can perform a rapid cooling or "quench," which can act as a heat treatment step. The argon gas is then released, captured, and recycled for future use.

The Goal: Healing Defects and Enhancing Properties

HIP is not merely a cosmetic treatment; it is a transformative process that fundamentally improves the material's internal quality. It is specified for components where structural failure is not an option.

Eliminating Internal Porosity

The primary purpose of HIP for castings is densification. Nearly all casting processes can leave behind microscopic pockets of gas or shrinkage voids. These defects act as stress concentrators and are the initiation points for cracks and fatigue failure. HIP effectively eliminates them.

Improving Mechanical Performance

By creating a fully dense, void-free structure, HIP dramatically improves a casting's mechanical properties. This includes a significant increase in tensile ductility, fracture toughness, and, most importantly, fatigue strength.

Reducing Property Scatter

A critical benefit for engineering is that HIP reduces the variability, or "scatter band," of material properties from one casting to the next. This creates a much more predictable and reliable component, simplifying design and raising safety factors.

Understanding the Trade-offs

While powerful, HIP is not a universal solution for every casting. It is an additional process step with specific considerations.

Cost and Cycle Time

HIP is an investment. The equipment is expensive, and the process cycles are long, often lasting 8 to 12 hours. This adds cost and lead time, which must be justified by the performance requirements of the final part.

Primarily for Internal Defects

HIP is exceptionally effective at healing internal, subsurface defects. It will not fix porosity or cracks that are open to the component's surface, as the pressurizing gas will simply fill those voids and prevent them from closing.

Process Control is Critical

The specific parameters—temperature, pressure, and time—must be carefully tailored to the specific alloy being treated. Improper settings can negatively affect the material's microstructure and compromise its final properties.

How to Apply This to Your Project

Specifying HIP is a strategic decision driven by the end-use requirements of the component. It is the bridge between a standard casting and a part ready for a mission-critical application.

- If your primary focus is mission-critical performance: Specify HIP for any cast component where failure could have catastrophic consequences, such as in aerospace structures or medical implants.

- If your primary focus is extending component life: Use HIP for parts subjected to high cyclic loading, like turbine blades or engine blocks, to maximize fatigue resistance.

- If your primary focus is production reliability: Consider HIP to reduce rejection rates and inspection costs by healing internal flaws that would otherwise cause parts to fail quality control.

- If your primary focus is a cost-sensitive, non-critical part: The added expense and time of the HIP process may not provide a worthwhile return on investment.

Ultimately, integrating Hot Isostatic Pressing transforms casting into a method for producing fully dense, highly reliable components fit for the most demanding applications.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary Function | Eliminates internal porosity & voids in castings |

| Key Benefit | Increases fatigue strength, ductility, and reliability |

| Ideal For | Aerospace, medical implants, turbine blades, and other critical components |

| Process Medium | High-temperature inert gas (argon) with uniform pressure |

| Typical Cycle Time | 8-12 hours |

Ready to transform your castings into mission-critical components? KINTEK specializes in advanced thermal processing solutions, including HIP consulting and equipment. Whether you're in aerospace, medical, or energy, our expertise ensures your parts meet the highest standards of density and performance. Contact our experts today to discuss how HIP can enhance your manufacturing process.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance