In advanced materials science, hot pressing is a powerful consolidation technique where powdered materials are simultaneously compacted by high pressure and heated (sintered) in a single operation. The raw powder is loaded into a die, typically made of graphite, which is then heated while mechanical force is applied. This dual action dramatically accelerates the process of turning loose powder into a dense, solid material.

The central advantage of hot pressing is its ability to use pressure as a catalyst for sintering. By forcing material particles together at high temperatures, it achieves higher densities and improved material properties more efficiently than heat-alone methods, making it ideal for high-performance applications.

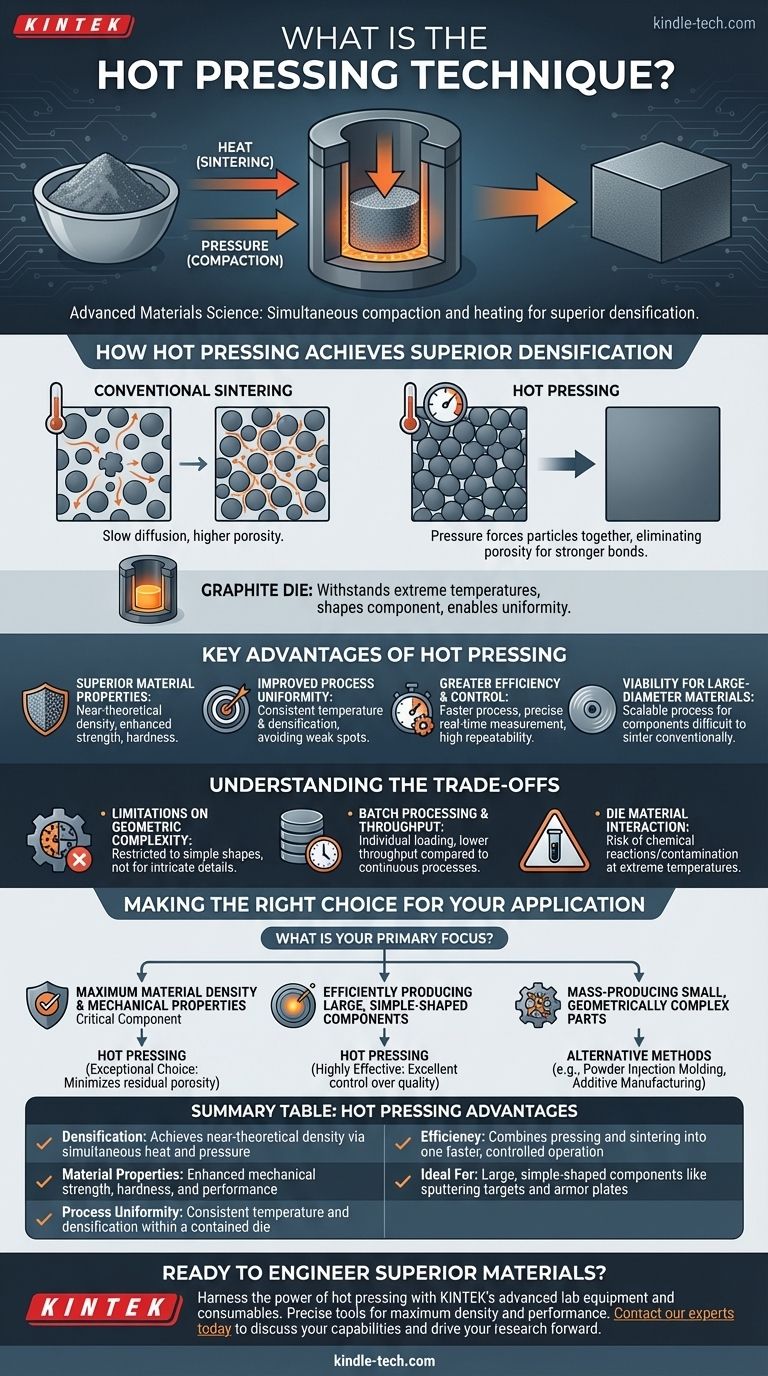

How Hot Pressing Achieves Superior Densification

The effectiveness of hot pressing lies in its direct, simultaneous application of the two key ingredients for material consolidation: heat and pressure.

The Core Mechanism

At high temperatures, material particles become more malleable. The applied mechanical pressure forces these softened particles into close contact, eliminating the empty spaces (porosity) between them and promoting strong atomic bonds. This is a much more direct path to densification than relying on temperature alone.

Enhanced Sintering Dynamics

In conventional sintering, densification occurs slowly as atoms diffuse across particle boundaries over time. Hot pressing bypasses this slower mechanism by physically closing the gaps, resulting in a faster process and a final product with significantly lower porosity.

The Role of the Graphite Die

The process typically occurs within a graphite press or die. Graphite is chosen for its ability to withstand extreme temperatures and its compressive strength. The die contains the powder and shapes the final component, making the process suitable for producing simple geometries like discs, blocks, and cylinders.

Key Advantages of the Hot Pressing Method

Choosing this technique offers several distinct operational and quality benefits over other consolidation processes.

Superior Material Properties

The primary advantage is the quality of the final product. The applied pressure helps produce materials that are near their theoretical maximum density, leading to enhanced mechanical strength, hardness, and other performance characteristics.

Improved Process Uniformity

The combination of direct pressure and heating within a contained die leads to a more uniform temperature field throughout the workpiece. This results in consistent densification and microstructure, avoiding the weak spots or internal stresses that can arise from uneven sintering.

Greater Efficiency and Control

By combining pressing and sintering, the overall manufacturing time and energy consumption can be significantly reduced. Modern hot presses integrated with IT systems allow for precise real-time measurement and control over temperature and pressure, ensuring high repeatability and quality control.

Viability for Large-Diameter Materials

Hot pressing is a scalable process and is often used to prepare large-diameter materials that would be difficult or time-consuming to densify using conventional furnace sintering.

Understanding the Trade-offs

While powerful, hot pressing is not a universal solution. Its advantages come with inherent limitations that must be considered.

Limitations on Geometric Complexity

The use of a rigid die means hot pressing is generally restricted to producing simple shapes. It is not suitable for creating parts with intricate details or complex internal features.

Batch Processing and Throughput

Hot pressing is fundamentally a batch process. Each component or set of components must be individually loaded, processed, and removed. This results in lower throughput compared to continuous processes, making it less ideal for high-volume mass production.

Die Material Interaction

The workpiece is in direct contact with the die material (e.g., graphite) at extreme temperatures. This introduces the risk of chemical reactions or carbon contamination, which must be managed for certain sensitive materials.

Making the Right Choice for Your Application

Selecting the right manufacturing process depends entirely on your end goal.

- If your primary focus is achieving maximum material density and superior mechanical properties for a critical component: Hot pressing is an exceptional choice, as the applied pressure minimizes residual porosity.

- If your primary focus is efficiently producing large, simple-shaped components like sputtering targets or armor plates with high uniformity: This method is highly effective and provides excellent control over the final material quality.

- If your primary focus is mass-producing small, geometrically complex parts: You should explore alternative methods like powder injection molding or additive manufacturing, which are designed for complexity and high throughput.

By understanding its mechanism of combining pressure and heat, you can leverage hot pressing to create high-performance materials engineered to meet the most demanding specifications.

Summary Table:

| Aspect | Hot Pressing Advantage |

|---|---|

| Densification | Achieves near-theoretical density via simultaneous heat and pressure |

| Material Properties | Enhanced mechanical strength, hardness, and performance |

| Process Uniformity | Consistent temperature and densification within a contained die |

| Efficiency | Combines pressing and sintering into one faster, controlled operation |

| Ideal For | Large, simple-shaped components like sputtering targets and armor plates |

Ready to Engineer Superior Materials?

Harness the power of hot pressing for your most demanding applications. KINTEK specializes in advanced lab equipment and consumables, providing the precise tools and expertise needed to achieve maximum material density and performance. Whether you're developing sputtering targets, armor plates, or other critical components, our solutions are engineered for reliability and control.

Contact our experts today to discuss how our hot pressing technology can enhance your laboratory's capabilities and drive your research forward.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Why is precise temperature control necessary for SiC/Cu Vacuum Hot Pressing? Mastering the Cu9Si Interface Phase

- What conditions does a Vacuum Hot Pressing Furnace provide for Copper-MoS2-Mo composites? Achieve Peak Densification

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- How does the uniaxial pressing function of a vacuum hot press furnace influence the microstructure of ZrC-SiC ceramics?