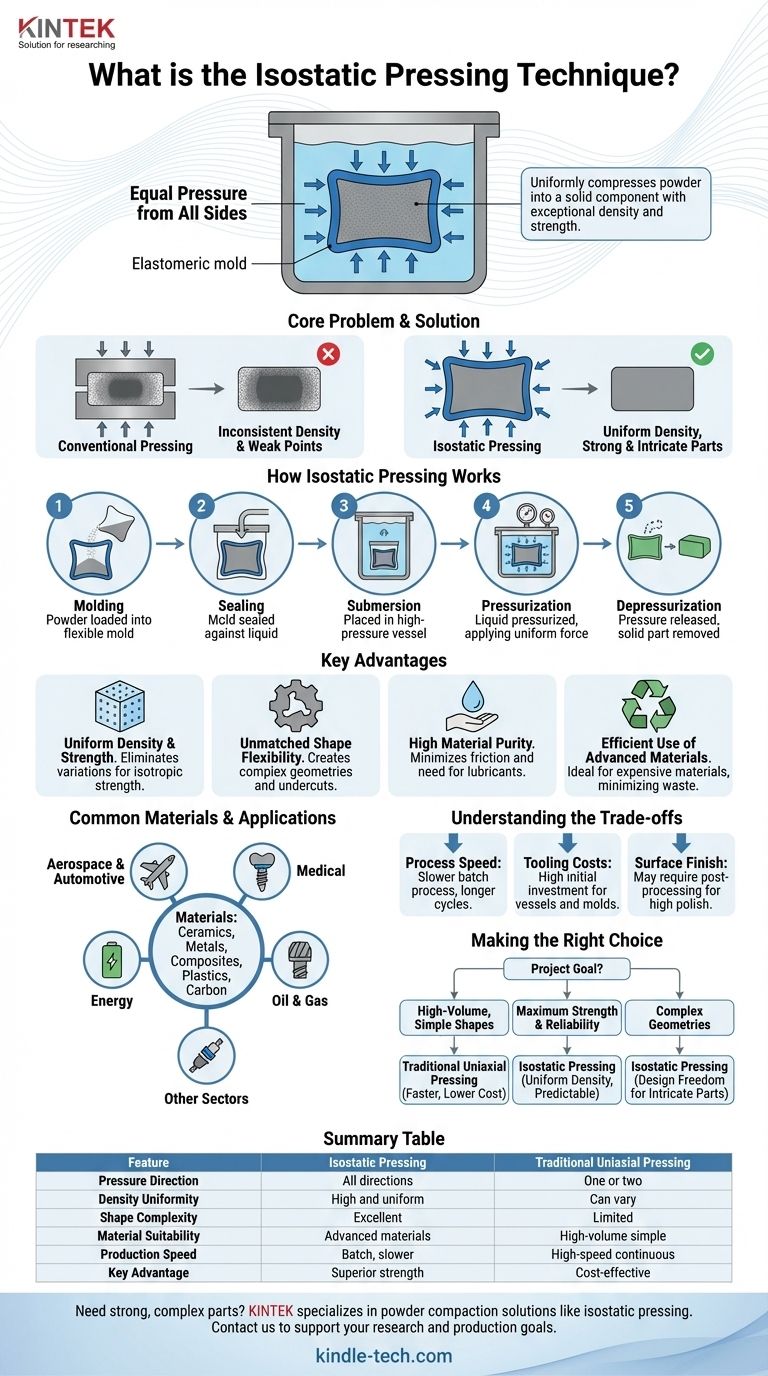

In materials science and manufacturing, isostatic pressing is a powder compaction technique that uses a pressurized liquid to uniformly compress a powder sealed within a flexible mold. Unlike traditional methods that press from one or two directions, this process applies equal pressure from all sides simultaneously. The result is a solid component with exceptionally uniform density and strength.

The core problem with conventional powder pressing is its inability to create complex shapes or achieve consistent density, leading to internal weaknesses. Isostatic pressing solves this by using fluid pressure to compact powders uniformly from all directions, enabling the production of strong, intricate parts that are impossible with other methods.

How Isostatic Pressing Works

Isostatic pressing leverages a fundamental principle of fluid dynamics to achieve its unique results. The process is elegant in its simplicity and highly effective.

The Core Principle: Hydrostatic Pressure

The technique operates on the principle that pressure exerted on a confined fluid is transmitted equally in all directions. When the flexible mold containing the powder is submerged, the liquid pressure acts on every point of its surface with the same force.

The Step-by-Step Process

- Molding: A dry or semi-dry powder is carefully loaded into a flexible, elastomeric mold made of rubber or plastic.

- Sealing: The mold is sealed to prevent the liquid from contaminating the powder.

- Submersion: The sealed mold is placed inside a high-pressure vessel filled with a liquid, typically water or oil.

- Pressurization: The liquid is pressurized, squeezing the flexible mold from all sides. This hydrostatic force is transmitted through the mold to uniformly compact the powder within.

- Depressurization: Once the desired density is reached, the pressure is released, and the compacted part, now a solid "green" body, is removed from the mold.

Why Choose Isostatic Pressing? The Key Advantages

Engineers and manufacturers choose this method when the limitations of conventional pressing become a barrier to performance or design.

Uniform Density and Strength

Because pressure is applied from all directions, the powder compacts evenly throughout the part. This eliminates the density variations and internal stress points common in uniaxial pressing, resulting in components with uniform, isotropic strength.

Unmatched Shape Flexibility

The use of a flexible mold removes many of the geometric constraints imposed by rigid metal dies. This allows for the creation of more complex shapes, including parts with undercuts or varying cross-sections, directly from the powder stage.

High Material Purity

The uniform pressure application minimizes friction between powder particles and the mold wall. This often eliminates the need for pressing lubricants, which can be a source of contamination and must be burned out in a later step.

Efficient Use of Advanced Materials

Isostatic pressing is ideal for difficult-to-compact or expensive materials, such as advanced ceramics and metal composites. It achieves high density with highly efficient material utilization, minimizing waste.

Common Materials and Applications

The versatility of isostatic pressing makes it a critical process across a wide range of high-performance industries.

Versatility Across Materials

This technique is used to consolidate a vast array of powdered materials. This includes ceramics, metals, composites, plastics, and carbon-based materials.

Critical Industrial Uses

You will find isostatically pressed components in demanding environments, including:

- Aerospace and Automotive: Manufacturing advanced ceramic components.

- Medical: Creating high-purity medical devices and implants.

- Energy: Forming parts for lithium-ion batteries and fuel cells.

- Oil & Gas: Producing high-performance components for extreme conditions.

- Other sectors: It is also used for pharmaceuticals, chemicals, nuclear fuel, and electrical connectors.

Understanding the Trade-offs

While powerful, isostatic pressing is not the universal solution for all powder compaction needs. It involves specific trade-offs compared to other methods.

Process Speed and Throughput

Isostatic pressing is typically a batch process, where parts are made one or a few at a time. This results in longer cycle times compared to the high-speed, continuous nature of automated uniaxial pressing, making it less suitable for very high-volume production of simple parts.

Tooling and Equipment Costs

The high-pressure vessels required are significant capital investments. Furthermore, while the flexible molds enable complex shapes, their design and fabrication can be more intricate and costly than a simple rigid die set, especially for ensuring durability under repeated high-pressure cycles.

Surface Finish Control

The final surface of the compacted part perfectly replicates the interior surface of the flexible mold. Achieving a highly polished finish may require more expensive tooling or additional post-processing steps compared to parts formed in polished steel dies.

Making the Right Choice for Your Application

Selecting the correct compaction method requires a clear understanding of your project's primary goal.

- If your primary focus is high-volume production of simple shapes: Traditional uniaxial die compaction is almost always faster and more cost-effective.

- If your primary focus is maximum strength and reliability: Isostatic pressing is the superior choice for creating components with uniform density and predictable performance.

- If your primary focus is creating complex geometries from powder: Isostatic pressing provides the design freedom necessary to produce intricate parts that are impossible with rigid tooling.

Ultimately, choosing the right powder consolidation technique is a strategic decision based on your specific requirements for geometry, performance, and production scale.

Summary Table:

| Feature | Isostatic Pressing | Traditional Uniaxial Pressing |

|---|---|---|

| Pressure Direction | All directions (hydrostatic) | One or two directions |

| Density Uniformity | High and uniform | Can vary, leading to weak points |

| Shape Complexity | Excellent for complex shapes, undercuts | Limited to simpler shapes |

| Material Suitability | Ideal for advanced ceramics, composites, metals | Best for high-volume, simple parts |

| Production Speed | Batch process, slower | High-speed, continuous |

| Key Advantage | Superior strength and reliability | Cost-effective for high volume |

Need to produce strong, complex parts with uniform density? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our expertise in powder compaction technologies like isostatic pressing can help you achieve superior material performance and reliability. Whether you're working with advanced ceramics, metal composites, or other specialized materials, we have the solutions to meet your demanding requirements. Contact us today to discuss how we can support your research and production goals!

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

People Also Ask

- What's the difference between cold press and regular press? Choosing Between Quality and Efficiency

- What is isostatic pressing in powder metallurgy? Unlock Superior Part Density and Complexity

- What is the cold isostatic pressing method? Achieve Uniform Density in Complex Parts

- What is hot isostatic pressing and cold isostatic pressing? Key Differences for Your Manufacturing Process

- What are the considerations of powder metallurgy? Key Factors for Manufacturing Success