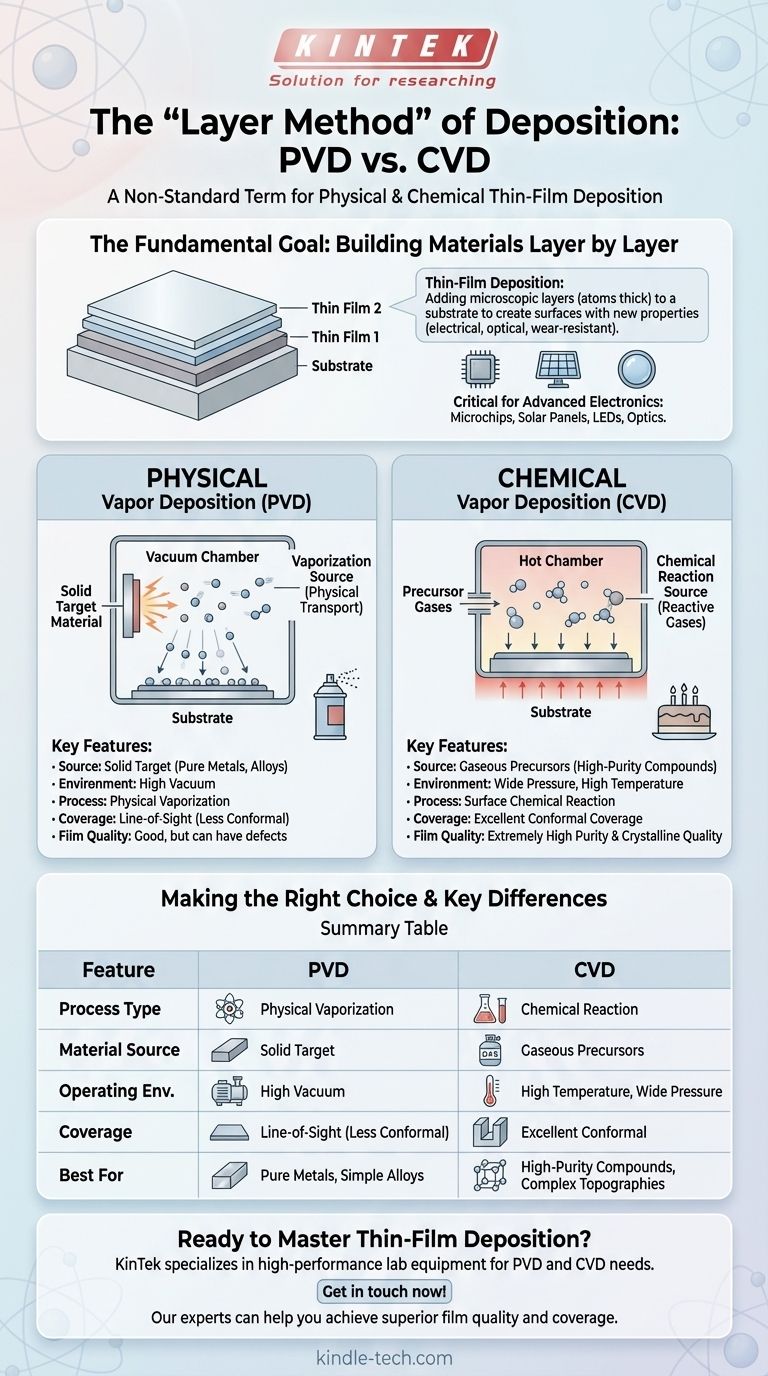

While "the layer method of deposition" is not a standard industry term, it accurately describes the goal of thin-film deposition: the process of applying a microscopic layer of material onto a surface or substrate. The two dominant professional methods for achieving this are Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD), which accomplish the same goal through fundamentally different means.

The term 'layer method' describes the desired outcome—building a material layer by layer. However, the critical distinction lies in how that layer is created: physically transporting a solid material (PVD) versus chemically reacting gases on a surface (CVD).

The Fundamental Goal: Building Materials One Layer at a Time

What is Thin-Film Deposition?

Thin-film deposition is a foundational process in modern engineering and materials science. It involves adding material, often just a few atoms or molecules thick, onto a base material known as a substrate.

The goal is to create a new surface with properties that the substrate alone does not possess, such as electrical conductivity, wear resistance, or specific optical qualities.

Why This Process is Critical

Nearly all advanced electronics rely on this process. Microchips, solar panels, LED screens, and optical lenses are all manufactured by meticulously depositing various thin films of conductors, semiconductors, and insulators onto a substrate.

The Two Primary Deposition Philosophies

To understand deposition, it's best to separate the methods into two major categories based on the source of the material: one physical, the other chemical.

Physical Vapor Deposition (PVD)

PVD is a process where a solid or liquid material is vaporized in a vacuum and transported as atoms or molecules to the substrate, where it condenses back into a solid film.

Think of it as an atomic-scale spray paint can. A solid target material is bombarded with energy (like an ion beam or electricity) until its atoms are ejected, travel through a vacuum, and stick to the substrate.

Chemical Vapor Deposition (CVD)

CVD uses volatile precursor gases that react or decompose on the substrate's surface to produce the desired solid deposit.

This is more like baking a cake. You introduce specific ingredient gases into a hot chamber. The heat on the substrate's surface acts as a catalyst, causing the gases to react and "bake" a solid, high-purity film onto it.

Understanding the Key Differences

The choice between PVD and CVD is driven by the desired film properties, the material being deposited, and the shape of the substrate.

The Source Material

In PVD, the source material is a solid target that is physically vaporized. This makes it excellent for depositing pure metals and alloys.

In CVD, the source material consists of one or more precursor gases. This method is ideal for creating highly pure compounds, such as silicon nitride or tungsten carbide.

Operating Conditions

PVD almost always requires a high vacuum to allow atoms from the source to travel to the substrate without colliding with other gas molecules.

CVD can be performed at a wider range of pressures, but it typically requires very high temperatures to drive the necessary chemical reactions on the substrate surface.

Film Quality and Purity

CVD is generally capable of producing films with extremely high purity and crystalline quality. The chemical reaction process can be precisely controlled to build perfect atomic structures.

PVD films are excellent for many applications, but they can sometimes have more structural defects or impurities compared to the best CVD films.

Conformal Coverage

Conformal coverage refers to the ability of a film to evenly coat a substrate with complex, non-flat features like trenches or steps.

Because CVD involves a gas that can reach all parts of a complex surface, it provides superior conformal coverage. PVD is a "line-of-sight" process, making it difficult to coat shadowed areas or the sides of deep trenches.

Making the Right Choice for Your Goal

Selecting the correct deposition method requires understanding the trade-offs between these two foundational techniques.

- If your primary focus is depositing pure metals or simple alloys with a direct line-of-sight: Physical Vapor Deposition (PVD) is typically the more direct and robust approach.

- If your primary focus is creating highly pure, uniform, and complex compound films that must coat intricate topographies: Chemical Vapor Deposition (CVD) offers superior control and conformal coverage.

Understanding the distinction between these physical and chemical pathways is the first step toward mastering modern material fabrication.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical vaporization of a solid target | Chemical reaction of precursor gases |

| Material Source | Solid target | Gaseous precursors |

| Operating Environment | High vacuum | Wide pressure range, high temperature |

| Coverage | Line-of-sight (less conformal) | Excellent conformal coverage |

| Best For | Pure metals, alloys | High-purity compounds, complex topographies |

Ready to Master Thin-Film Deposition in Your Lab?

Choosing between PVD and CVD is critical for your research or production quality. KINTEK specializes in providing high-performance lab equipment and consumables tailored to your deposition needs. Our experts can help you select the right system to achieve superior film quality, purity, and coverage.

Contact us today to discuss your project and discover how our solutions can enhance your laboratory's capabilities. Get in touch now!

Visual Guide

Related Products

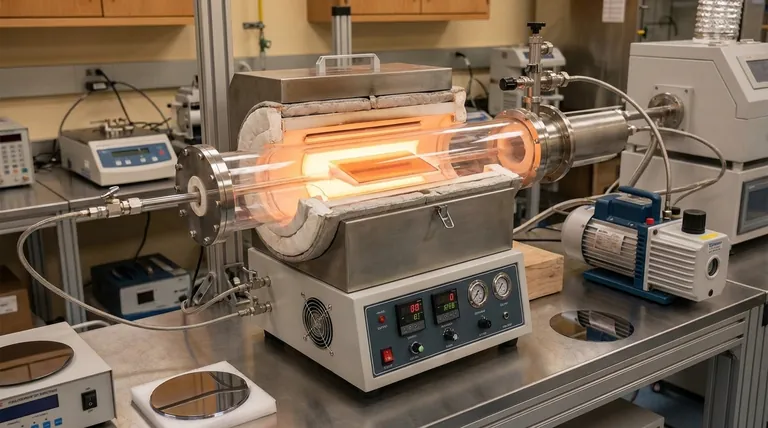

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application