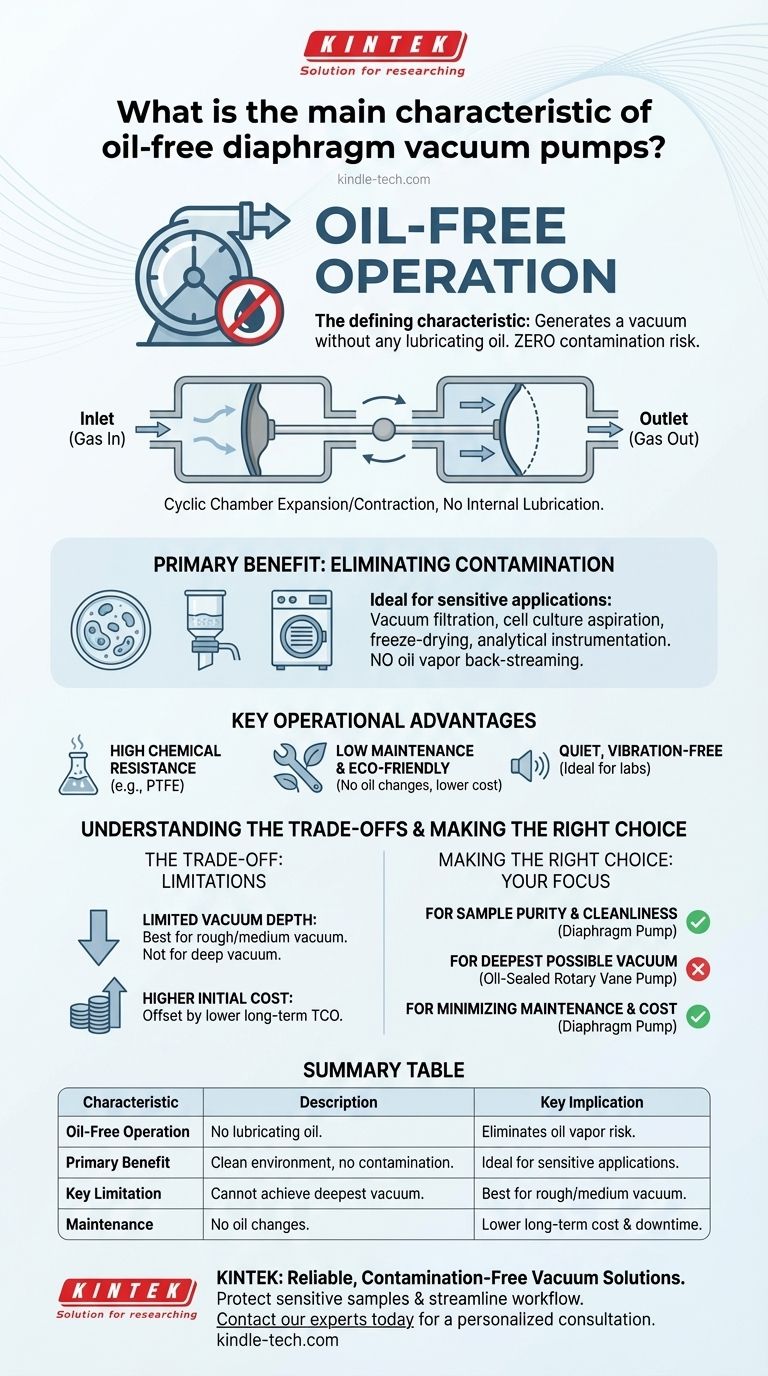

The defining characteristic of an oil-free diaphragm vacuum pump is its ability to generate a vacuum without any lubricating oil. This "dry" operation is the source of its primary advantages and its key limitations, making it ideal for applications where maintaining a clean, uncontaminated environment is non-negotiable.

The decision to use a diaphragm pump is a strategic choice for sample purity and low maintenance over achieving the absolute deepest vacuum levels. Understanding this core trade-off is the key to selecting the right tool for your work.

The Principle of Oil-Free Operation

At its core, a diaphragm pump is a positive displacement pump. It uses a flexible diaphragm, driven by a connecting rod, to cyclically expand and contract a chamber, moving gas from the inlet to the outlet without any internal lubrication.

The Primary Benefit: Eliminating Contamination

Because there is no oil, there is zero risk of oil vapor back-streaming into your vacuum chamber or process. This completely eliminates the possibility of contaminating sensitive samples, a critical factor in many scientific and manufacturing applications.

Ideal Applications for Cleanliness

This oil-free nature makes diaphragm pumps the standard choice for processes that cannot tolerate any impurities. Common uses include vacuum filtration, cell culture aspiration, freeze-drying, and moving gases in analytical instrumentation.

Key Operational Advantages

Beyond cleanliness, the oil-free design delivers several practical benefits that impact lab workflow and operational costs.

High Chemical Resistance

Many diaphragm pumps are constructed with materials like PTFE, making them highly resistant to corrosion. This allows them to handle viscous, acidic, and aggressive vapors common in chemical, cosmetic, and food production environments.

Low Maintenance and Environmental Impact

The absence of oil eliminates the most common maintenance task: oil changes. This not only reduces downtime and service costs but also removes the need to handle and dispose of contaminated pump oil, making it a more environmentally friendly option.

Quiet, Vibration-Free Performance

Designed for laboratory settings, these pumps typically run very quietly and with minimal vibration. This makes them an excellent choice for shared workspaces where noise can be a significant distraction.

Understanding the Trade-offs

While the benefits are significant, the oil-free design comes with inherent limitations that you must consider. Choosing a diaphragm pump means accepting a trade-off between cleanliness and ultimate vacuum power.

Limited Vacuum Depth

The primary limitation of a diaphragm pump is its maximum achievable vacuum. It cannot reach the deep vacuum levels of an oil-sealed rotary vane pump. They are best suited for rough to medium vacuum applications.

Higher Initial Purchase Cost

Generally, a diaphragm pump will have a higher upfront purchase price compared to a rotary vane pump with a similar flow rate. However, this is often offset by a lower total cost of ownership due to reduced maintenance and the absence of oil costs.

Performance Curve Considerations

When selecting a pump, you must evaluate its performance curve, which shows the relationship between its flow rate and vacuum level. A pump's effectiveness can drop significantly as it approaches its maximum vacuum, so it's crucial to choose a model that operates efficiently at your target pressure.

Making the Right Choice for Your Application

Your final decision must be guided by the specific demands of your experiment or process. The "best" pump is the one that aligns with your primary goal.

- If your primary focus is sample purity and a clean environment: The oil-free diaphragm pump is the definitive choice to prevent contamination.

- If your primary focus is achieving the deepest possible vacuum: An oil-sealed rotary vane pump is likely the necessary tool for the job.

- If your primary focus is minimizing maintenance and lifetime costs: The low-maintenance, oil-free design of a diaphragm pump offers a clear long-term advantage.

Ultimately, selecting the correct vacuum technology is about aligning the pump's inherent characteristics with the uncompromisable needs of your work.

Summary Table:

| Characteristic | Description | Key Implication |

|---|---|---|

| Oil-Free Operation | Generates a vacuum without lubricating oil. | Eliminates risk of sample contamination from oil vapor. |

| Primary Benefit | Maintains a clean, uncontaminated environment. | Ideal for sensitive applications (e.g., cell culture, analytical instrumentation). |

| Key Limitation | Cannot achieve the deepest vacuum levels of oil-sealed pumps. | Best for rough to medium vacuum applications. |

| Maintenance | No oil changes required. | Lower long-term cost of ownership and reduced downtime. |

Need a reliable, contamination-free vacuum for your lab?

KINTEK's oil-free diaphragm vacuum pumps are engineered to protect your sensitive samples and streamline your workflow. By eliminating oil, we help you prevent contamination in applications like vacuum filtration, freeze-drying, and cell culture, while significantly reducing maintenance time and costs.

Let us help you select the perfect pump for your specific needs. Contact our experts today for a personalized consultation and discover the KINTEK difference in laboratory performance and reliability.

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What is the difference between laser melting and sintering? A Guide to Particle Fusion Methods

- How do you test for filtration? Measure Upstream vs. Downstream for True Efficiency

- What temperature does KBr dry at for IR? The Key to Moisture-Free, High-Quality Spectra

- What is the primary purpose of using an ultrasonic cleaner for Pd/G-SS electrodes? Ensure Superior Coating Adhesion

- How do rotary vane pumps compare to liquid ring vacuum pumps? Choosing the Right Vacuum Pump for Your Process

- What materials are needed for a FTIR? Essential Guide to Sample Prep and Optics

- What is the difference between biomass briquettes and pellets? Choose the Right Fuel for Your Heating System

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C