Process annealing is a heat treatment primarily used to relieve internal stresses, reduce hardness, and increase the ductility of a metal. By heating a material to a specific temperature and then allowing it to cool slowly, annealing effectively "resets" its microstructure, making it softer and more workable for subsequent manufacturing operations.

Annealing is not an end goal but a critical bridge in manufacturing. It conditions a material by removing the brittleness induced by previous work, ensuring it can be successfully shaped, machined, or relied upon in service without fracturing.

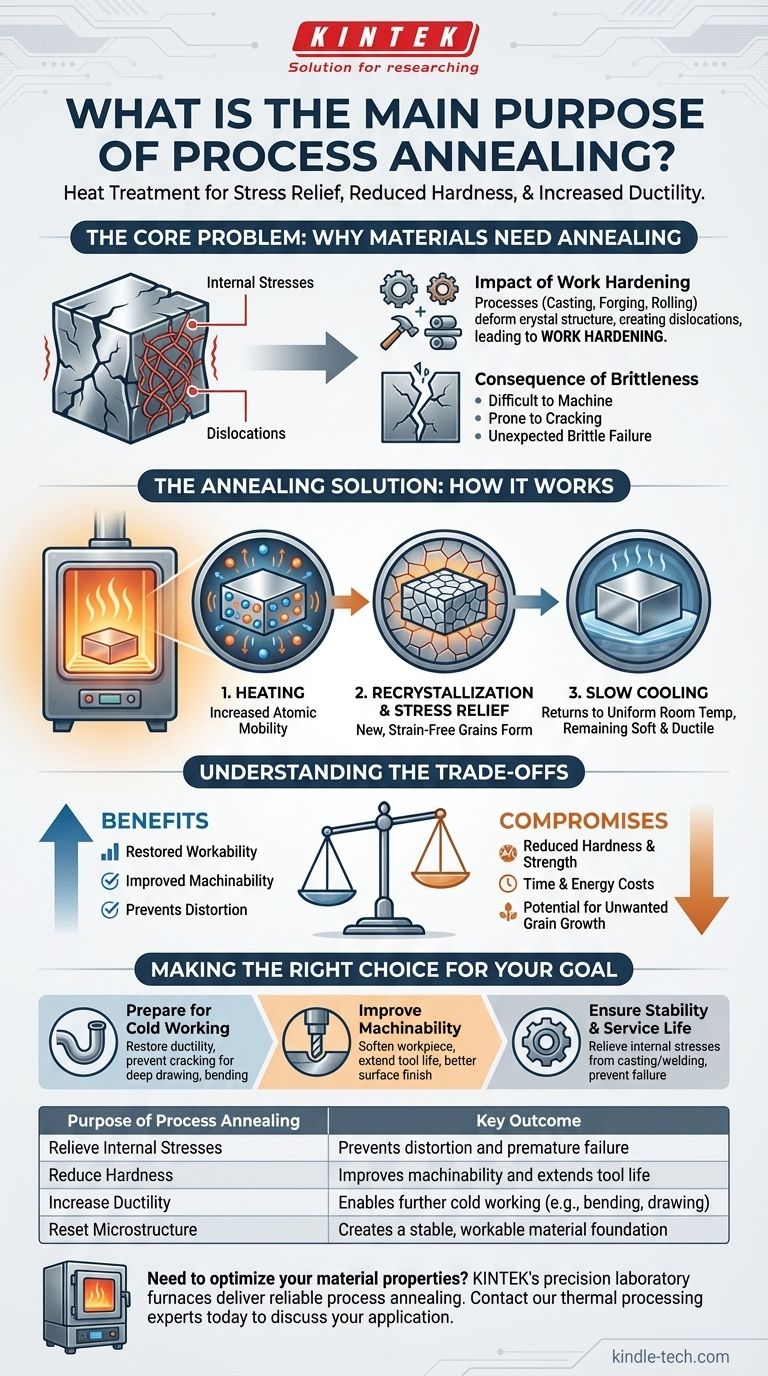

The Core Problem: Why Materials Need Annealing

Manufacturing processes fundamentally change a material's internal structure. Annealing is the solution to the undesirable side effects of these changes.

The Impact of Work Hardening

Processes like casting, forging, rolling, or drawing create internal stresses within a metal. These actions deform the material's crystal structure, creating and tangling imperfections known as dislocations.

As these dislocations pile up, they prevent the crystal planes from slipping past one another. This phenomenon, known as work hardening, makes the material harder and stronger, but also significantly less ductile and more brittle.

The Consequence of Brittleness

A hard, brittle material is a major liability in manufacturing and in service.

It is difficult to machine, causing rapid tool wear and poor surface finishes. It is also prone to cracking when subjected to forming operations like bending or stamping. Most critically, the locked-in internal stresses can lead to unexpected, brittle failure when the part is put under load.

The Annealing Solution: How It Works

Annealing reverses the effects of work hardening through a carefully controlled thermal cycle of heating, holding, and cooling.

The Role of Heat

Heating a material provides the thermal energy necessary for its atoms to vibrate and move more freely. This increased atomic mobility allows the distorted crystal lattice to begin relaxing and repairing itself.

Recrystallization and Stress Relief

When held at the correct annealing temperature, the material undergoes recrystallization. New, strain-free crystal grains form and grow, consuming the old, deformed grains that were filled with dislocations.

This process eliminates the vast majority of the internal stress and restores the material's orderly crystal structure.

The Importance of Slow Cooling

After holding at temperature, the material must be cooled slowly, often by simply letting it cool down inside the furnace. This slow cooling rate is critical.

Rapid cooling would lock in new thermal stresses and could re-harden the material. Slow cooling allows the entire part to return to room temperature uniformly, ensuring it remains soft, ductile, and in a stable, low-energy state.

Understanding the Trade-offs

While essential, annealing is not without its compromises. Understanding them is key to using the process effectively.

Reduced Hardness and Strength

The primary trade-off is that annealing significantly reduces a material's hardness and tensile strength. While this is the goal for improving workability, the softened state may not be suitable for the final application.

Often, annealing is an intermediate step. A part might be annealed to allow for forming, and then subjected to a different heat treatment (like hardening and tempering) to achieve the final desired strength.

Time and Energy Costs

Annealing is an energy-intensive process. It requires heating large furnaces to high temperatures, holding them for a set duration, and then undergoing a long cooling cycle. This consumes significant time and energy, adding to the overall cost of manufacturing.

Potential for Unwanted Grain Growth

If the annealing temperature is too high or the holding time is too long, the new, strain-free grains can become excessively large. Overly large grains can sometimes reduce the material's toughness and lead to a poor surface finish after subsequent forming operations.

Making the Right Choice for Your Goal

Apply annealing when the goal is to restore a material's workability and stability.

- If your primary focus is preparing a material for further cold working: Use annealing to restore ductility and prevent cracking during processes like deep drawing, bending, or wire drawing.

- If your primary focus is improving machinability: Anneal the workpiece to soften it, which extends tool life, reduces cutting forces, and results in a better surface finish.

- If your primary focus is ensuring stability and service life: Use annealing to relieve internal stresses from casting or welding, preventing distortion over time or premature failure under load.

Ultimately, process annealing gives you control over a material's fundamental properties, transforming it from a brittle, stressed state into a stable and workable foundation.

Summary Table:

| Purpose of Process Annealing | Key Outcome |

|---|---|

| Relieve Internal Stresses | Prevents distortion and premature failure |

| Reduce Hardness | Improves machinability and extends tool life |

| Increase Ductility | Enables further cold working (e.g., bending, drawing) |

| Reset Microstructure | Creates a stable, workable material foundation |

Need to optimize your material properties for manufacturing? KINTEK's precision laboratory furnaces are engineered for reliable and consistent process annealing. Whether you're preparing materials for complex forming, improving machinability, or ensuring long-term part stability, our equipment delivers the precise temperature control required for superior results. Contact our thermal processing experts today to discuss your application and discover the right annealing solution for your laboratory.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What temperature does steel liquify? Understanding the Melting Range for Your Applications

- How to use a muffle furnace in a laboratory? A Step-by-Step Guide to Safe, Precise Thermal Processing

- How is the sintering temperature related to the melting temperature? A Guide to Solid-State Bonding

- What energy transfer happens in a furnace? Master Convection, Conduction & Radiation for Your Process

- What is the purpose of a muffle furnace? Achieve High-Purity Heating for Your Lab