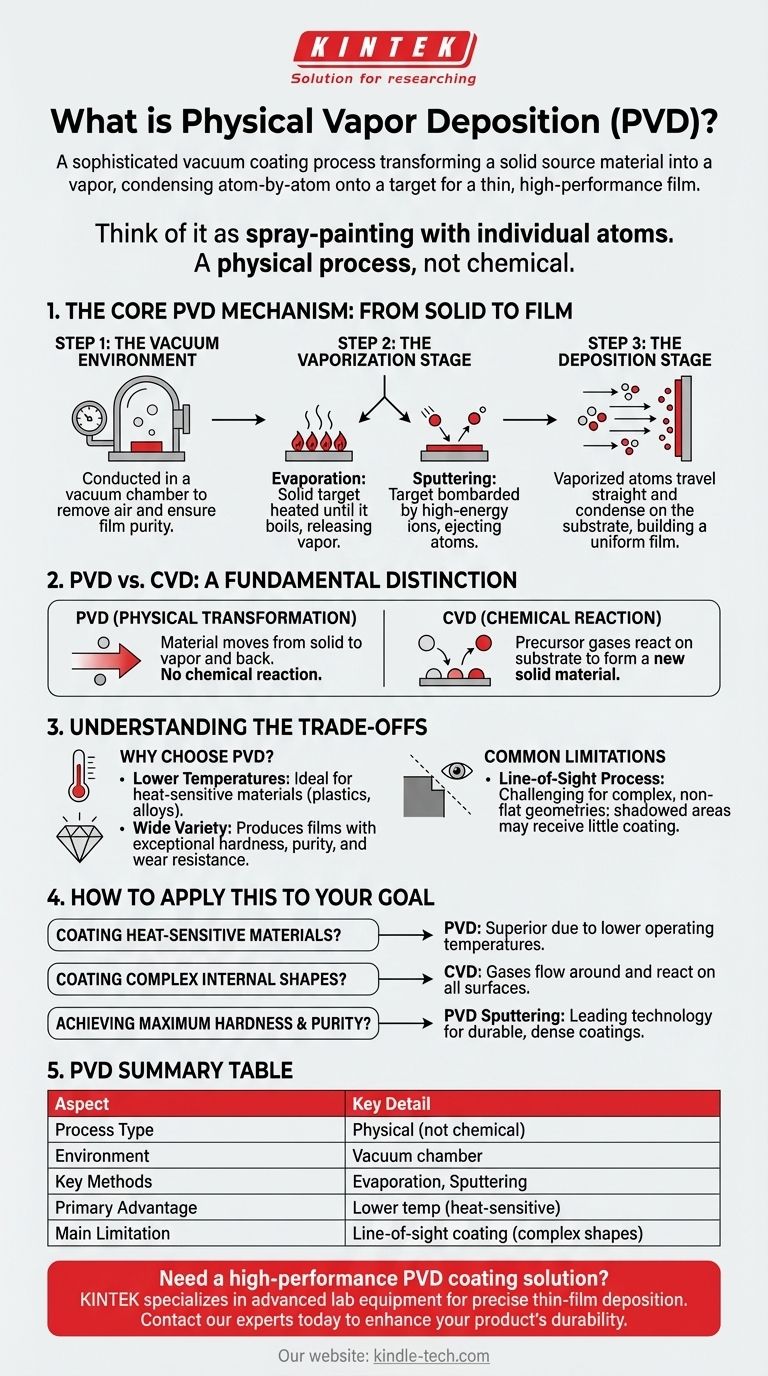

At its core, Physical Vapor Deposition (PVD) is a sophisticated coating process that takes place in a vacuum. It works by transforming a solid source material into a vapor, which then travels atom-by-atom across a chamber and condenses onto a target object, forming an extremely thin, high-performance film.

The critical distinction to understand is that PVD is a purely physical process—think of it as spray-painting with individual atoms. This separates it from Chemical Vapor Deposition (CVD), which relies on a chemical reaction to form the coating on a surface.

The Core PVD Mechanism: From Solid to Film

PVD is not a single method but a family of coating techniques. However, all PVD processes share a fundamental, three-stage mechanism that occurs within a controlled, low-pressure environment.

The Vacuum Environment

The entire PVD process is conducted inside a vacuum chamber. This is essential to remove air and other gaseous particles that could otherwise react with or impede the vaporized coating material, ensuring the purity and quality of the final film.

The Vaporization Stage

The first active step is to convert the solid coating material (known as the "target") into a vapor. The two most common methods for achieving this are:

- Evaporation: The target material is heated in the vacuum until it melts and then boils, releasing a vapor of atoms that travel through the chamber.

- Sputtering: The target is bombarded with high-energy ions (typically from an inert gas like argon). This energetic collision acts like a microscopic sandblaster, knocking individual atoms off the target surface and ejecting them into the chamber.

The Deposition Stage

Once vaporized, the atoms or small clusters of atoms travel in a straight line through the vacuum chamber. When they strike the surface of the object to be coated (the "substrate"), they condense back into a solid state, gradually building a thin, uniform, and tightly bonded film.

PVD vs. CVD: A Fundamental Distinction

Understanding the difference between PVD and its common alternative, Chemical Vapor Deposition (CVD), is crucial for appreciating its unique applications.

The PVD Process: A Physical Transformation

In PVD, the material of the final coating is the same material as the source target. The process simply moves the material from one location to another by changing its physical state from solid to vapor and back to solid. No fundamental chemical reaction creates the film.

The CVD Process: A Chemical Reaction

In contrast, CVD introduces one or more volatile precursor gases into the chamber. These gases decompose and react with each other on the substrate's surface, forming an entirely new solid material as the coating. The film itself is the product of this chemical reaction.

Understanding the Trade-offs

Choosing a deposition technology requires understanding its inherent advantages and limitations. While both PVD and CVD produce high-quality thin films, their underlying mechanisms lead to different outcomes.

Why Choose PVD?

PVD processes are generally conducted at lower temperatures than most CVD processes. This makes PVD an excellent choice for coating temperature-sensitive materials, such as plastics or certain metal alloys, that could be damaged by high heat.

Furthermore, PVD offers a wide variety of coating materials and can produce films with exceptional hardness, purity, and wear resistance.

Common Limitations

Because PVD is typically a "line-of-sight" process, where atoms travel in a straight line from the source to the substrate, it can be challenging to coat complex, non-flat geometries uniformly. The interior surfaces or shadowed areas of an object may receive little to no coating.

How to Apply This to Your Goal

Your choice between deposition technologies depends entirely on the material you are coating and the properties you need in the final product.

- If your primary focus is coating heat-sensitive materials: PVD is almost always the superior choice due to its lower operating temperatures.

- If your primary focus is coating complex internal shapes: CVD is often more suitable, as the precursor gases can flow around and react on all surfaces of an object.

- If your primary focus is achieving maximum hardness and purity: PVD sputtering is a leading technology for creating exceptionally durable and dense coatings for tools and medical implants.

By understanding the core principle of a physical transfer versus a chemical reaction, you can confidently determine the right technology for your engineering challenge.

Summary Table:

| PVD Aspect | Key Detail |

|---|---|

| Process Type | Physical (not chemical) |

| Environment | Vacuum chamber |

| Key Methods | Evaporation, Sputtering |

| Primary Advantage | Lower temperature, ideal for heat-sensitive materials |

| Main Limitation | Line-of-sight coating (challenging for complex shapes) |

Need a high-performance PVD coating solution for your lab or manufacturing process? KINTEK specializes in advanced lab equipment and consumables for precise thin-film deposition. Our expertise ensures you get the right coating technology for your specific materials and performance requirements. Contact our experts today to discuss how our PVD solutions can enhance your product's durability and functionality.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications