In short, mechanical press forging is a high-speed manufacturing process that uses a flywheel-powered ram to shape a heated metal workpiece in a single, rapid stroke. Unlike the repeated blows of a hammer, a mechanical press applies its force in one continuous motion, squeezing the metal into the shape of a closed die. This method is renowned for its speed, precision, and repeatability.

The core principle to understand is that mechanical press forging sacrifices the brute force flexibility of a hammer or the controlled squeeze of a hydraulic press for one primary benefit: unmatched production speed and consistency. It is the definitive choice for mass-producing high-precision components.

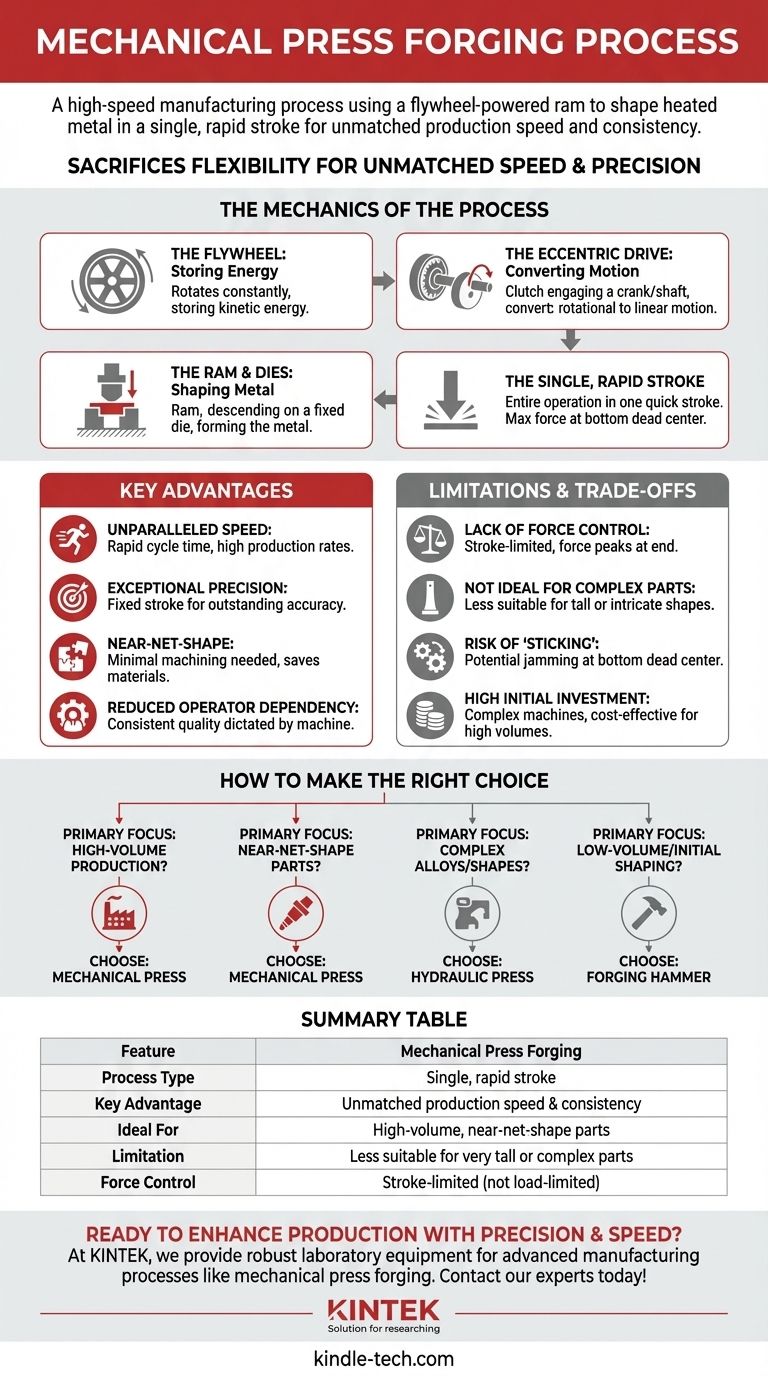

The Mechanics of the Process

At its heart, a mechanical press is a machine designed to convert rotational energy into a linear force with exceptional efficiency. The process is a masterpiece of mechanical engineering, relying on a few key components working in perfect sync.

The Flywheel: Storing the Energy

The process begins with a large, heavy flywheel that is kept spinning by an electric motor. This constantly rotating wheel acts as a mechanical battery, storing a massive amount of kinetic energy.

The Eccentric Drive: Converting Motion

When the operator initiates a cycle, a clutch engages, connecting the spinning flywheel to an eccentric crank or shaft. This mechanism masterfully converts the flywheel's continuous rotational motion into the single, powerful, up-and-down linear motion of the ram.

The Ram and Dies: Shaping the Metal

The ram holds the top half of a hardened steel die. The bottom half is fixed to the press bed. A heated, malleable workpiece is placed on the bottom die, and the ram descends, forcing the metal to flow and fill the die cavity completely.

The Single, Rapid Stroke

The defining characteristic is that the entire forging operation happens in one quick stroke. The press delivers a predetermined amount of energy and force, with the maximum force being exerted at the very bottom of the stroke, an instant known as the "bottom dead center."

Key Advantages of Mechanical Presses

Choosing mechanical press forging is a strategic decision driven by the need for efficiency and precision at scale. Its advantages are clear and significant for the right application.

Unparalleled Production Speed

The rapid cycle time—a single stroke per part—makes mechanical presses the fastest forging method available. This allows for extremely high production rates, often producing thousands of parts per hour.

Exceptional Repeatability and Precision

Because the ram has a fixed stroke length, it stops at the exact same position every single time. This results in outstanding dimensional accuracy and consistency from one part to the next, which is difficult to achieve with operator-dependent methods like hammer forging.

Near-Net-Shape Forgings

The high precision allows for the production of near-net-shape parts. These components are forged so close to their final dimensions that they require very little secondary machining, saving significant time, material waste, and cost.

Reduced Operator Dependency

While still requiring skilled oversight, the process is far less reliant on the operator's individual skill and judgment compared to hammer forging. The machine's inherent consistency dictates the final part quality.

Understanding the Trade-offs and Limitations

No process is perfect for every scenario. The strengths of mechanical forging are balanced by a specific set of limitations that are critical to understand.

Lack of Force Control

The force of the press is not constant throughout the stroke; it peaks only at the very end. The process is stroke-limited, not load-limited. This means you cannot apply a specific tonnage for a set amount of time, a capability found in hydraulic presses.

Not Ideal for Complex or Tall Parts

The fixed, relatively short stroke makes mechanical presses less suitable for forging very tall or intricate components. The single, rapid squeeze may not provide enough time for the metal to flow into deep or complex die cavities.

The Risk of "Sticking"

Because the maximum energy is expended at the bottom of the stroke, there is a risk of the press jamming or "sticking" if the workpiece is too large, too cold, or improperly placed. This can cause significant downtime and potential damage to the machine.

High Initial Investment

Mechanical forging presses are complex, massive machines that represent a significant capital investment. Their cost is typically only justified by the high-volume production runs that leverage their speed.

How to Make the Right Choice

Selecting the correct forging method comes down to aligning the process capabilities with your specific production goals.

- If your primary focus is high-volume mass production: The unmatched speed and automation of mechanical press forging make it the clear and superior choice.

- If your primary focus is creating near-net-shape parts to minimize machining: The exceptional repeatability and dimensional accuracy of a mechanical press are its greatest strengths.

- If your primary focus is forging complex alloys or highly intricate shapes: A hydraulic press, with its slow and controlled squeeze, is likely the better technical solution.

- If your primary focus is low-volume runs or initial shaping of large ingots: The versatility and lower tooling cost of a forging hammer may be more appropriate.

Ultimately, mechanical press forging is the engine of modern manufacturing, trading operational flexibility for unparalleled production speed and precision.

Summary Table:

| Feature | Mechanical Press Forging |

|---|---|

| Process Type | Single, rapid stroke |

| Key Advantage | Unmatched production speed & consistency |

| Ideal For | High-volume, near-net-shape parts |

| Limitation | Less suitable for very tall or complex parts |

| Force Control | Stroke-limited (not load-limited) |

Ready to enhance your production line with precision and speed?

At KINTEK, we specialize in providing robust laboratory equipment and consumables to support advanced manufacturing processes like mechanical press forging. Whether you are in R&D, quality control, or process optimization, our solutions help ensure material integrity and production efficiency.

Let's discuss how KINTEK can support your laboratory and production goals. Contact our experts today to find the right equipment for your needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

People Also Ask

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation

- How does a laboratory hydraulic press contribute to the preparation of green pellets for nanostructured eutectic steel?

- What is the hydraulic forging process? Master the Art of High-Strength Metal Forming

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- What role does a laboratory hydraulic press play in all-solid-state battery fabrication? Enhancing Ion Conductivity