In essence, the method of Physical Vapor Deposition (PVD) is a vacuum-based coating technique where a solid source material is converted into a vapor, transported across a vacuum chamber, and then condensed onto the surface of a part (the substrate) to form a very thin, high-performance film. The entire process occurs atom-by-atom in a highly controlled environment without any fundamental chemical reactions changing the source material itself.

The core principle of PVD is a physical journey. It involves using high energy in a vacuum to liberate atoms from a solid source and redeposit them as a dense, high-purity coating onto a target object.

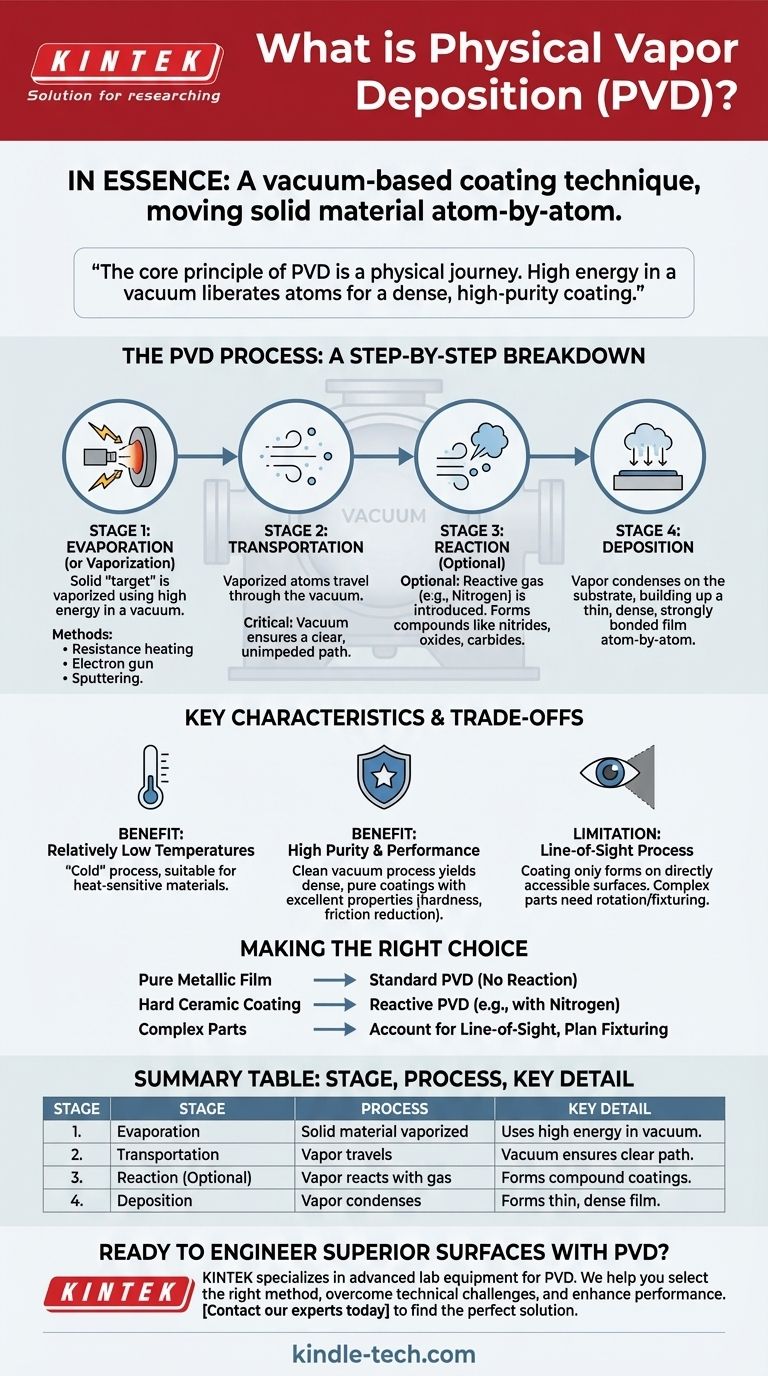

The PVD Process: A Step-by-Step Breakdown

To truly understand the PVD method, it's best to think of it as a carefully controlled, four-stage journey for atoms, all taking place inside a high-vacuum chamber.

Stage 1: Evaporation (or Vaporization)

The first step is to generate a vapor from the solid coating material, often called the "target." This isn't like boiling water; it requires significant energy to liberate atoms from the solid.

This is achieved by bombarding the target material with a high-energy source. Common methods include resistance heating, using an electron gun, or sputtering, which involves bombarding the target with high-energy ionized gas (plasma).

Stage 2: Transportation

Once freed, the vaporized atoms or molecules travel through the vacuum chamber. The vacuum is critical here.

Without a vacuum, the vaporized particles would collide with air molecules, losing energy and preventing them from ever reaching the substrate in a clean, controlled way. The vacuum ensures a clear, unimpeded path from the source to the part being coated.

Stage 3: Reaction (An Optional but Critical Step)

In many advanced applications, this is where PVD becomes highly versatile. For a simple, pure metal coating, this step is skipped.

However, if a specific compound coating (like a ceramic) is desired, a controlled amount of a reactive gas (such as nitrogen, oxygen, or methane) is introduced into the chamber. The vaporized metal atoms react with this gas to form new compounds like nitrides, oxides, or carbides.

Stage 4: Deposition

This is the final stage where the coating is formed. The vaporized material (either pure or reacted) reaches the substrate, which is comparatively cool.

Upon contact, the vapor condenses back into a solid state, building up on the substrate's surface one atom at a time. This atomic-level buildup is what creates an extremely thin, dense, and strongly bonded film.

Key Characteristics and Trade-offs

Understanding the PVD method also means understanding its inherent properties and limitations.

Benefit: Relatively Low Temperatures

PVD is considered a "cold" process compared to other coating techniques like Chemical Vapor Deposition (CVD). This allows for the coating of materials that might be damaged or warped by high heat.

Benefit: High Purity and Performance

Because it happens in a vacuum, the process is extremely clean. The resulting coatings are very pure and dense, leading to excellent properties like increased hardness, reduced friction, and improved oxidation resistance.

Limitation: Line-of-Sight Process

A primary trade-off is that PVD is fundamentally a line-of-sight process. The coating can only form on surfaces that the vaporized atoms can directly travel to from the source. Coating complex, internal geometries can be challenging without sophisticated part rotation and manipulation.

Making the Right Choice for Your Goal

Your application will determine which variation of the PVD method is most suitable.

- If your primary focus is a pure, unadulterated metallic film: You require a standard, non-reactive PVD process where the "reaction" step is omitted.

- If your primary focus is a hard, wear-resistant ceramic coating: You will need a reactive PVD process where a gas like nitrogen or oxygen is introduced to form a new compound.

- If your primary focus is coating a complex part with hidden surfaces: You must account for the line-of-sight limitation and plan for complex part fixturing and rotation.

Ultimately, PVD is a method for physically engineering a surface at the atomic level to achieve properties the base material could never have on its own.

Summary Table:

| Stage | Process | Key Detail |

|---|---|---|

| 1. Evaporation | Solid coating material is vaporized. | Uses high energy (e.g., sputtering, electron beam) in a vacuum. |

| 2. Transportation | Vapor travels across the chamber. | Vacuum ensures a clear path to the substrate. |

| 3. Reaction (Optional) | Vapor reacts with a gas (e.g., Nitrogen). | Forms compound coatings like nitrides or carbides. |

| 4. Deposition | Vapor condenses on the substrate surface. | Forms a thin, dense, and strongly bonded film atom-by-atom. |

| Key Benefit | Creates hard, wear-resistant, and pure coatings. | Process occurs at relatively low temperatures. |

| Key Limitation | Line-of-sight process. | Coating complex geometries requires specialized fixturing. |

Ready to Engineer Superior Surfaces with PVD?

KINTEK specializes in providing the advanced lab equipment and expert consumables needed to implement PVD coating processes effectively. Whether you are developing hard, wear-resistant ceramic coatings or pure metallic films, our solutions help you achieve precise, high-performance results.

We help you:

- Select the right PVD method for your specific material and application goals.

- Overcome technical challenges like coating complex parts with our specialized expertise.

- Enhance product performance with durable, high-purity coatings.

Let's discuss how PVD can transform your products. Contact our experts today to find the perfect solution for your laboratory's coating needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating