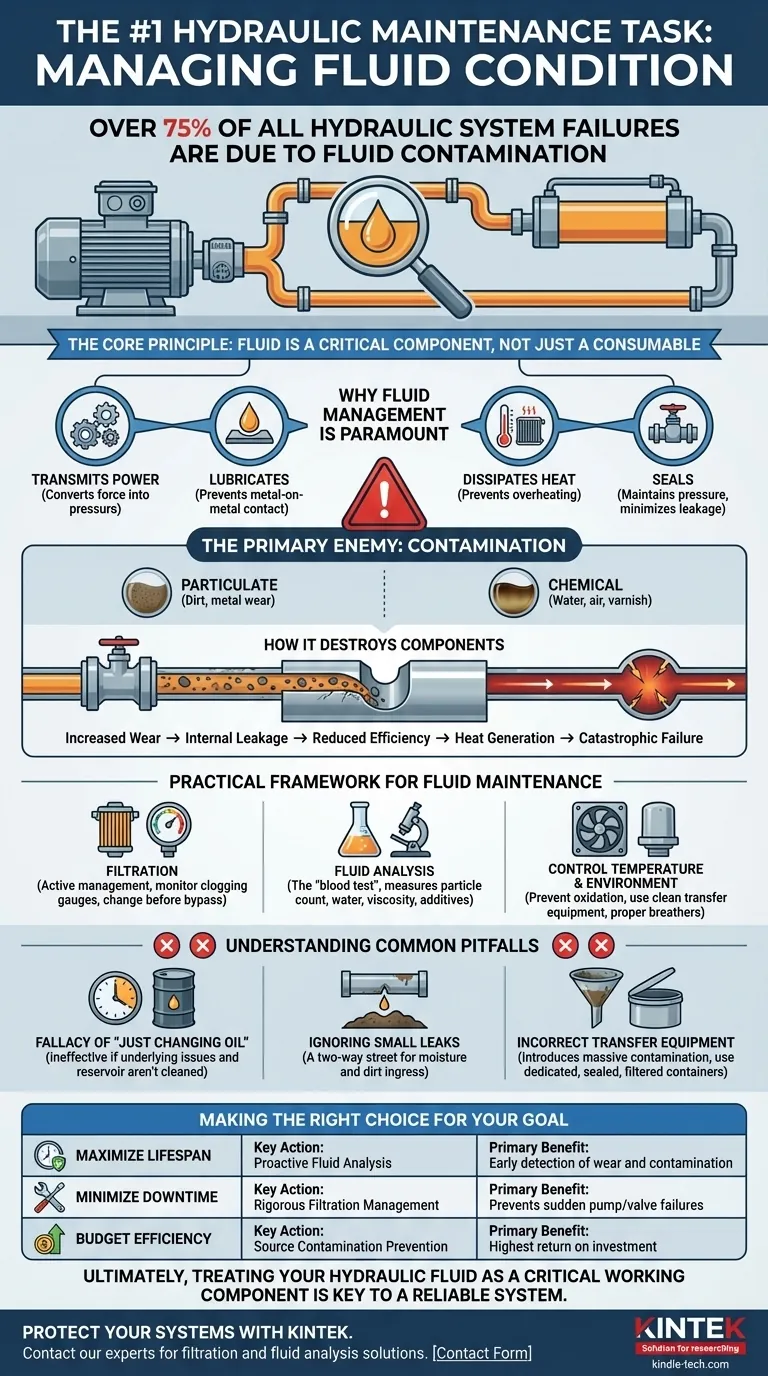

Without question, the single most important maintenance task in any hydraulic system is managing the condition of the hydraulic fluid. While mechanical checks are necessary, over 75% of all hydraulic system failures are a direct result of fluid contamination. Therefore, maintaining the cleanliness, temperature, and integrity of the fluid is the highest-leverage activity you can perform.

The core principle of effective hydraulic maintenance is to shift your perspective: the fluid isn't just a consumable, it is the most critical component in the system. Protecting the fluid is the most effective way to protect every other component it touches, from the pump to the actuators.

Why Fluid Management is Paramount

To understand why fluid is so critical, you must first understand its role beyond simply transmitting power. The fluid is the lifeblood of the machine, performing multiple essential functions simultaneously.

The Four Functions of Hydraulic Fluid

First, it transmits power. This is its primary and most obvious job, converting mechanical force at the pump into pressure that can do work.

Second, it lubricates all moving components. The microscopic film of oil prevents metal-on-metal contact in pumps, motors, and valves, which operate under immense pressure with extremely tight tolerances.

Third, it dissipates heat. As the fluid circulates, it carries heat away from components like the pump and valves to the reservoir or a heat exchanger, preventing overheating.

Finally, it seals the minute clearances between moving parts, such as between a valve spool and its housing, ensuring pressure is maintained and internal leakage is minimized.

The Primary Enemy: Contamination

Contamination is any foreign substance in the hydraulic fluid. It is the root cause of the vast majority of component failures.

Contaminants come in two main forms: particulate (dirt, dust, metal wear particles, seal fragments) and chemical (water, air, varnish from fluid breakdown).

How Contamination Destroys Components

Particulate contamination acts like liquid sandpaper inside your system. Abrasive particles get caught in the tight clearances of pumps and valves, scoring and eroding precision surfaces.

This initial damage creates a chain reaction. The wear generates more metal particles, which accelerates the wear on other components. This leads to internal leakage, reduced system efficiency, increased heat generation, and eventual catastrophic failure.

A Practical Framework for Fluid Maintenance

Effective fluid management is not a single action but a systematic process. It involves preventing contaminants from entering and removing those that inevitably do.

Filtration: Your First Line of Defense

Filters are designed to capture and remove particulate contamination from the fluid as it circulates. A robust filtration plan is non-negotiable.

This involves monitoring filter condition indicators (clogging gauges) and changing elements before they go into bypass mode. Simply having filters isn't enough; they must be actively managed.

Fluid Analysis: Seeing Inside Your System

Regular oil sampling and analysis is the equivalent of a blood test for your machine. It is the only way to know the true condition of your fluid and your system.

Analysis reveals the particle count (cleanliness level), water content, fluid viscosity, and the health of the additive package. This data allows you to move from reactive (fixing failures) to proactive (preventing failures) maintenance.

Controlling Temperature and Environment

Heat is a form of energy that degrades hydraulic fluid, causing it to break down (oxidize) and form sludge and varnish. Ensure heat exchangers and cooling systems are functioning correctly.

Furthermore, control the environment where fluid is stored and transferred. A new drum of oil is often not clean enough for a modern hydraulic system. Use dedicated, clean transfer equipment and proper breathers on reservoirs to prevent ingesting airborne dirt and moisture.

Understanding the Common Pitfalls

Many well-intentioned maintenance programs fall short because of a few common misconceptions. Avoiding them is critical for success.

The Fallacy of "Just Changing the Oil"

Simply changing the fluid on a time-based schedule can be wasteful and ineffective. It does not address any underlying issues causing contamination.

If you drain contaminated fluid but don't clean the reservoir and fix the source of the contamination (like a bad seal or breather), the new fluid will be contaminated almost immediately.

Ignoring Small Leaks

A small external leak is often dismissed as a nuisance. However, a leak is a two-way street. When the system is off, that same path that allows oil to seep out can allow moisture and dirt to be drawn in.

Treat every leak not just as a loss of fluid, but as a critical breach in your system's defense against contamination.

Using Incorrect Transfer Equipment

Using dirty, open containers or shared funnels to top-off hydraulic fluid is one of the most common ways to introduce a massive amount of contamination.

Always use dedicated, sealed transfer containers with built-in filtration to ensure you are adding clean fluid to the system.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your operational priorities. By focusing on the fluid, you can tailor your approach to meet specific goals.

- If your primary focus is maximizing equipment lifespan: Prioritize a proactive fluid analysis program. This data-driven approach allows you to detect and correct contamination, chemical breakdown, and wear issues long before they cause permanent damage.

- If your primary focus is minimizing immediate downtime: Implement a rigorous filtration management plan. Ensure filters are correctly sized and serviced, as this is your most active defense against the contamination that causes sudden valve and pump failures.

- If your primary focus is budget efficiency: Concentrate on preventing contamination at its source. Improving fluid storage and handling procedures, using high-quality breathers, and promptly sealing all leaks provides the highest return on investment.

Ultimately, treating your hydraulic fluid as a critical working component, not just a consumable, is the key to a reliable and long-lasting system.

Summary Table:

| Maintenance Focus | Key Action | Primary Benefit |

|---|---|---|

| Maximize Lifespan | Proactive Fluid Analysis | Early detection of wear and contamination |

| Minimize Downtime | Rigorous Filtration Management | Prevents sudden pump and valve failures |

| Budget Efficiency | Source Contamination Prevention | Highest return on investment |

Protect your hydraulic systems and optimize your maintenance strategy. KINTEK specializes in laboratory equipment and consumables, including filtration and fluid analysis solutions that help you maintain system integrity and prevent costly downtime. Contact our experts today to discuss how we can support your laboratory's specific hydraulic maintenance needs.

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- Why KBr is used for pellet? Master FTIR Sample Prep for Clear, Reliable Spectra

- What should the mortar and pestle be cleaned with before preparing a KBr pellet for IR? Ensure Accurate IR Spectroscopy Results

- How does a hydraulic press facilitate bipolar all-solid-state battery assembly? Enhance Cell Density & Ionic Flow

- What role does a laboratory hydraulic press and specialized mold play in zirconium alloys? Ensuring High-Performance Green Body Production

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- How much force does a hydraulic press exert? From Benchtop 10-Ton to Industrial 100,000-Ton Power

- What happens when hydraulics overheat? Prevent Catastrophic System Failure and Costly Downtime

- Why is a laboratory hydraulic press used to apply 510 MPa for Li3PS4 and Na3PS4? Achieve Optimal Electrolyte Density