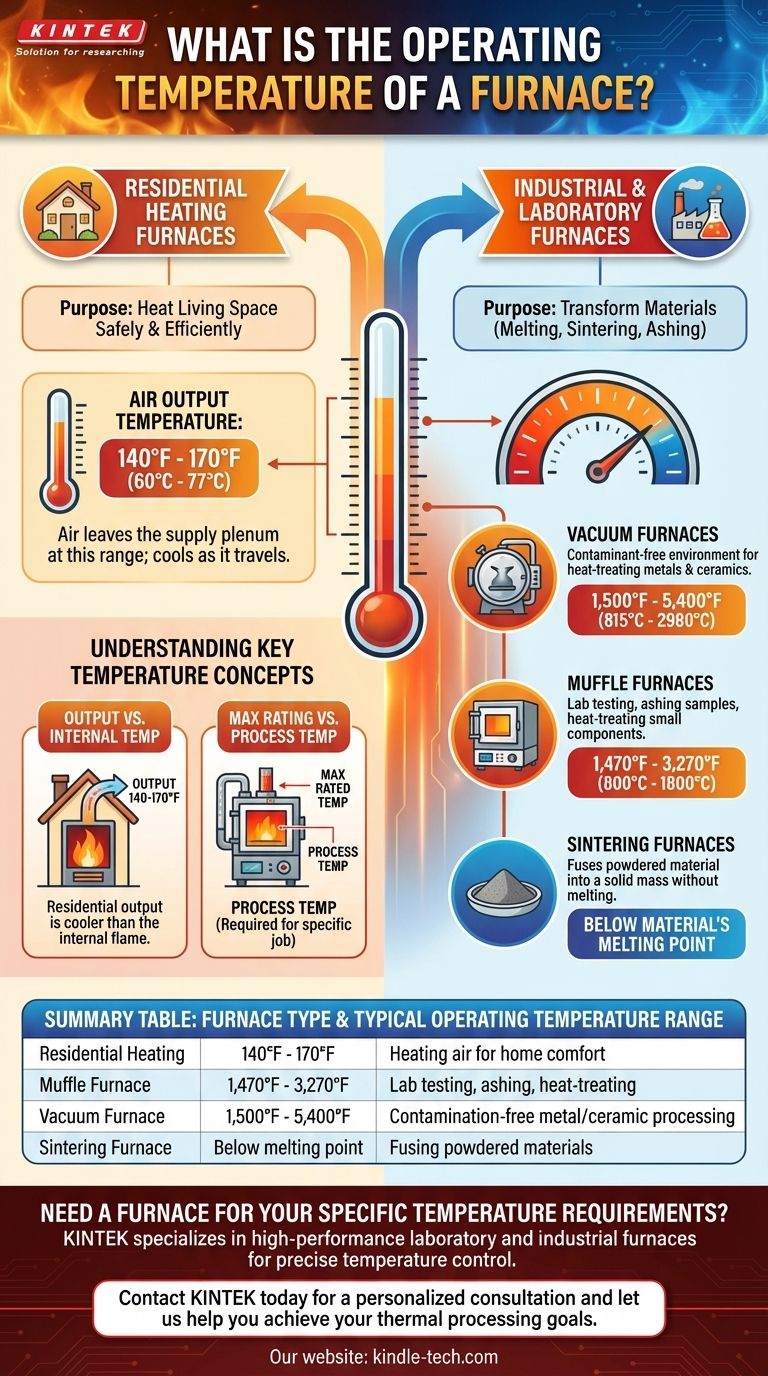

The operating temperature of a furnace depends entirely on its purpose. For a residential furnace that heats a home, the air it produces is typically between 140°F and 170°F. However, industrial and laboratory furnaces operate at vastly higher temperatures, often reaching thousands of degrees to melt or chemically alter materials.

A furnace has no single operating temperature. The term applies to everything from a home heating unit running below 200°F to an industrial system capable of exceeding 5,000°F. The correct temperature is always defined by the specific task.

The Two Worlds of Furnaces: Home vs. Industrial

The fundamental source of confusion is that the word "furnace" describes two very different categories of equipment with completely different goals.

Residential Heating Furnaces

A home furnace is designed for a single purpose: to heat the air in your living space safely and efficiently.

The key measurement is the temperature of the air leaving the furnace's supply plenum. This air consistently ranges from 140°F to 170°F (60°C to 77°C).

By the time this air travels through ductwork and enters a room through a vent, its temperature may have dropped significantly.

Industrial & Laboratory Furnaces

Industrial furnaces are not designed to heat air but to transform materials. Their function is to apply a specific, often extreme, amount of heat to a product.

These systems operate at much higher temperatures, as their purpose is to induce physical or chemical changes like melting, sintering, or ashing.

The required temperature is dictated entirely by the material being processed and the desired outcome.

A Closer Look at High-Temperature Furnaces

Different industrial processes require specialized furnaces capable of maintaining precise and extreme temperatures.

Vacuum Furnaces

These systems create a controlled, contaminant-free environment for heat-treating metals and ceramics.

Vacuum furnaces have a very wide maximum operating range, typically between 1,500°F and 5,400°F (815°C to 2980°C).

Muffle Furnaces

Often found in laboratories, muffle furnaces are used for high-temperature testing, ashing samples, or heat-treating small components.

Their operating range is generally between 1,470°F and 3,270°F (800°C to 1800°C).

Sintering Furnaces

Sintering is a process that uses heat to fuse powdered material into a solid mass without melting it.

The operating temperature is therefore highly specific: it must be just below the material's melting point to achieve the desired result.

Understanding Key Temperature Concepts

To speak accurately about furnace temperature, it's critical to distinguish between different measurements and ratings.

Output Temperature vs. Internal Temperature

For a home furnace, the 140°F to 170°F range refers to the heated air it outputs. The temperature of the actual flame inside the combustion chamber is significantly hotter.

This distinction is crucial for both safety and diagnostics.

Maximum Rating vs. Process Temperature

An industrial furnace has a maximum rated temperature it can safely achieve.

However, the actual temperature used for a specific job is called the process temperature. This is the functional temperature required to properly treat the material inside.

How to Determine the Right Temperature

Use the furnace's application to determine the relevant temperature range.

- If your primary focus is a home heating system: The air temperature at the supply vents should be in the range of 140°F-170°F when the system is running.

- If your primary focus is an industrial process: The material's properties dictate the required process temperature, which then determines the type of furnace you must use.

- If your primary focus is laboratory work: You must select a furnace (e.g., muffle, vacuum) whose operating range comfortably exceeds the temperature requirements of your experiment.

Ultimately, a furnace's temperature is a direct reflection of the work it is designed to perform.

Summary Table:

| Furnace Type | Typical Operating Temperature Range | Primary Application |

|---|---|---|

| Residential Heating | 140°F to 170°F (60°C to 77°C) | Heating air for home comfort |

| Muffle Furnace | 1,470°F to 3,270°F (800°C to 1800°C) | Lab testing, ashing, heat-treating |

| Vacuum Furnace | 1,500°F to 5,400°F (815°C to 2980°C) | Contamination-free metal/ceramic processing |

| Sintering Furnace | Below material's melting point | Fusing powdered materials into solids |

Need a Furnace for Your Specific Temperature Requirements?

Choosing the right furnace is critical to your project's success. KINTEK specializes in high-performance laboratory and industrial furnaces, including muffle and vacuum furnaces, designed to deliver precise and reliable temperature control for applications from basic ashing to advanced material synthesis.

Our experts will help you select the perfect equipment to meet your exact process temperature needs, ensuring safety, efficiency, and repeatable results.

Contact KINTEK today for a personalized consultation and let us help you achieve your thermal processing goals.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What role do high-temperature furnaces play in LFR corrosion testing? Achieve Critical Thermal Stability

- How to do vacuum casting? A Step-by-Step Guide to Flawless Prototypes and Low-Volume Parts

- What are industrial vacuum systems? A Guide to Boosting Efficiency in Material Handling & Processing

- What is the difference between firing and sintering in ceramics? Master the Art vs. Science of Heat Treatment

- Why are ceramics sintered? Transform Powder into High-Performance Solid Components

- How does heat treating make metal stronger? Optimize Your Metal's Strength and Durability

- How does pyrolysis work? Unlock the Power of Thermal Decomposition for Waste Transformation

- Why are high-temperature closed furnaces and vacuum desiccators essential for pre-treating eutectic salt raw materials?