At its core, Physical Vapor Deposition (PVD) is a vacuum-based coating process where a solid source material is converted into a vapor, transported through a vacuum chamber, and condensed onto a substrate to form a thin, high-performance film. This entire process occurs in a high-vacuum environment and builds the coating atom by atom, allowing for exceptional purity and control.

PVD is not a single technique but rather a family of processes. The unifying principle is the physical transformation of a material from a solid to a vapor and back to a solid film, all without inducing a chemical reaction on the substrate's surface.

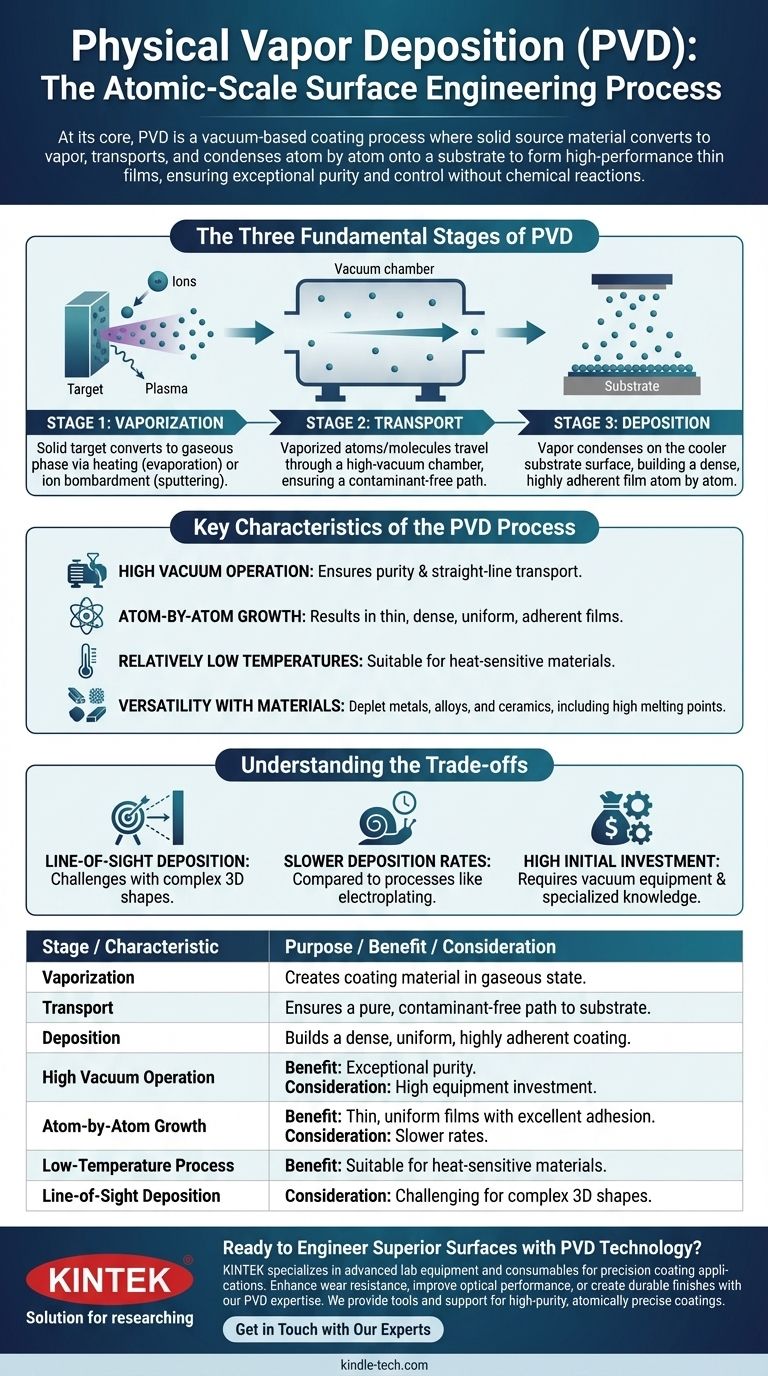

The Three Fundamental Stages of PVD

The PVD process, regardless of the specific method used, can be broken down into three distinct and sequential stages. Understanding this sequence is key to understanding how the technology works.

Stage 1: Vaporization

The process begins by converting a solid source material, often called a "target," into a gaseous or vapor phase. The specific method used for this conversion is what distinguishes the different types of PVD.

This can be achieved by heating the material until it evaporates or by bombarding it with high-energy ions from a plasma, which physically knocks atoms from the target's surface in a process known as sputtering.

Stage 2: Transport

Once vaporized, these atoms or molecules travel through a high-vacuum chamber. The vacuum is critical because it removes other particles, like air, that would otherwise collide with and contaminate the vapor stream.

This near-empty environment ensures the vaporized particles have a clean, unimpeded path from the source material to the object being coated (the substrate).

Stage 3: Deposition

When the vapor particles reach the cooler surface of the substrate, they condense back into a solid state. This condensation builds a thin, dense, and highly adherent film on the substrate's surface.

Because this film grows one atom at a time, the final coating is extremely uniform and can be controlled with high precision.

Key Characteristics of the PVD Process

Several core characteristics define PVD and differentiate it from other coating methods. These features are the source of both its unique advantages and its specific limitations.

Operation in a High Vacuum

The process is fundamentally dependent on a very low-pressure environment. This vacuum ensures the purity of the final coating by eliminating potential reactions with ambient gases and allows for the straight-line transport of vapor particles.

Atom-by-Atom Growth

PVD builds coatings layer by layer at an atomic level. This results in films that are exceptionally thin, dense, and uniform, with excellent adhesion to the substrate.

Relatively Low Temperatures

Compared to processes like Chemical Vapor Deposition (CVD), PVD operates at significantly lower temperatures. This makes it suitable for coating heat-sensitive materials that would otherwise be damaged by high-temperature processes.

Versatility with Materials

PVD can be used to deposit a wide variety of materials, including metals, alloys, and ceramics. It is particularly effective for depositing materials with very high melting points that are difficult to process using other methods.

Understanding the Trade-offs

While powerful, the PVD process has inherent limitations that must be considered for any practical application.

Line-of-Sight Deposition

The vapor particles travel in a straight line from the source to the substrate. This "line-of-sight" nature makes it challenging to evenly coat the surfaces of complex, three-dimensional shapes without sophisticated part rotation and manipulation.

Slower Deposition Rates

The meticulous, atom-by-atom nature of PVD often results in slower coating speeds compared to processes like electroplating. This can make it less economical for applications requiring very thick films.

High Initial Investment

PVD equipment, which requires high-vacuum chambers, power supplies, and control systems, represents a significant capital investment. The complexity of the process requires specialized knowledge to operate and maintain.

Making the Right Choice for Your Goal

The decision to use PVD is driven by the desired outcome, as its properties make it ideal for specific high-performance applications.

- If your primary focus is durability and wear resistance: PVD is the standard for creating extremely hard coatings on cutting tools, medical implants, and aerospace components.

- If your primary focus is optical or electrical performance: The process is essential for depositing the highly pure, uniform thin films required for semiconductors, optical filters, and solar cells.

- If your primary focus is a high-end decorative finish: PVD provides a brilliant and long-lasting metallic finish for items like watches, faucets, and firearms, offering a more environmentally friendly alternative to traditional plating.

By controlling a purely physical process in a vacuum, PVD provides an unparalleled level of precision in engineering surfaces at the atomic scale.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| 1. Vaporization | Solid target material is converted into a vapor via evaporation or sputtering. | Creates the coating material in a gaseous state. |

| 2. Transport | Vapor particles travel through a high-vacuum chamber. | Ensures a pure, contaminant-free path to the substrate. |

| 3. Deposition | Vapor condenses on the substrate surface, forming a thin film. | Builds a dense, uniform, and highly adherent coating atom by atom. |

| Key Characteristic | Benefit | Consideration |

| High Vacuum Operation | Exceptional coating purity and straight-line particle transport. | Requires significant equipment investment. |

| Atom-by-Atom Growth | Thin, dense, and highly uniform films with excellent adhesion. | Results in slower deposition rates compared to other methods. |

| Low-Temperature Process | Suitable for coating heat-sensitive materials. | - |

| Line-of-Sight Deposition | - | Can be challenging for complex 3D shapes without part manipulation. |

Ready to Engineer Superior Surfaces with PVD Technology?

KINTEK specializes in providing advanced lab equipment and consumables for precision coating applications. Whether your goal is to enhance wear resistance, improve optical performance, or create durable decorative finishes, our expertise in PVD processes can help you achieve unparalleled results.

We provide the tools and support to leverage high-purity, atomically precise coatings for your most demanding projects. Contact us today to discuss how our solutions can meet your specific laboratory needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- How does chemical vapor deposition work for carbon nanotubes? A Guide to Controlled Synthesis

- How do vane components optimize thin film quality in Vertical HPS-CVD? Achieve Superior Layer Control

- What does chemical vapor deposition do? Create High-Performance Thin Films for Advanced Manufacturing

- What is CVD coating advantages and disadvantages? Achieve Superior Wear Resistance or Risk Brittleness

- What is a metal organic chemical vapor deposition? A Guide to High-Purity Thin Film Growth

- What are methods of thin film fabrication? A Guide to PVD vs. CVD Techniques

- What is the pressure for sputtering? Optimize Your Thin Film Density and Coverage

- What is a thin film technology? The Atomic-Scale Process Powering Modern Electronics