At its core, Physical Vapor Deposition (PVD) is not a single method but a family of vacuum-based coating processes. The foundational theory involves using purely physical mechanisms—such as heating or bombardment—to transform a solid material into a vapor. This vapor then travels through a vacuum and condenses onto a target object, known as a substrate, to form a very thin, high-performance film.

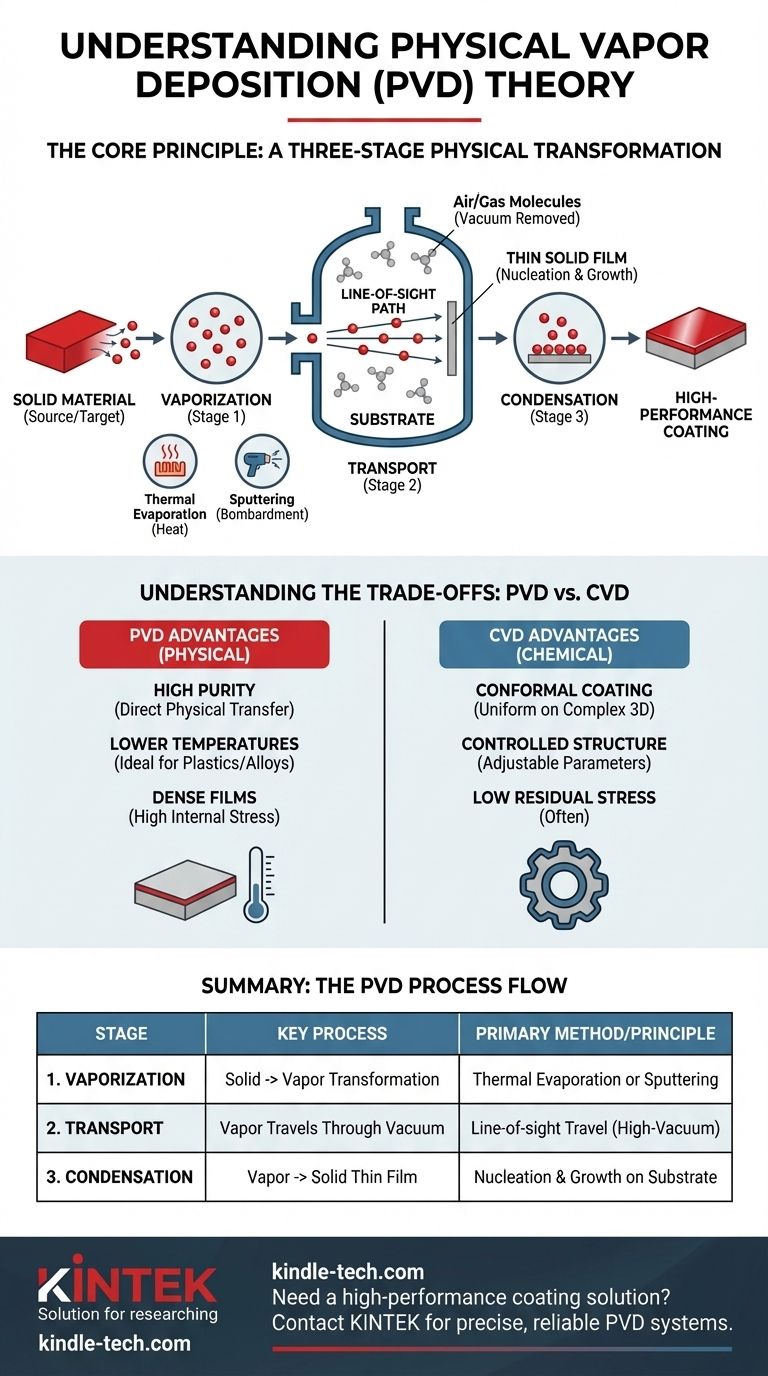

The central principle of PVD is a three-stage physical transformation: a solid material is vaporized, transported through a vacuum, and then condensed back into a solid film on a substrate. Unlike chemical processes, the material's fundamental chemical identity remains unchanged from start to finish.

The Core Principles of PVD

To truly understand PVD, it is best to break it down into its three distinct physical stages. The success of the entire process depends on the precise control of each step within a high-vacuum environment.

Stage 1: Vaporization

The first step is to generate vapor from a solid source material, often called the "target." This is accomplished primarily through two different physical methods.

- Thermal Evaporation: This method uses heat. The source material is heated in a high vacuum until it reaches a temperature where it begins to evaporate, turning directly from a solid into a gas. This vapor then fills the chamber.

- Sputtering: This is a more energetic method. A solid target is bombarded with high-energy ions (typically from an inert gas like Argon). This bombardment acts like a microscopic sandblaster, physically knocking atoms off the target's surface and ejecting them into the vacuum chamber.

Stage 2: Transport

Once atoms are ejected from the source material, they travel through the vacuum chamber. This stage is why the vacuum is so critical.

The high-vacuum environment removes air and other gas molecules that would otherwise collide with the traveling vapor atoms. Without a vacuum, the atoms would be scattered, slowed down, or react with other gases, preventing a clean and direct path to the substrate. This direct, unimpeded travel is often described as "line-of-sight" deposition.

Stage 3: Condensation

When the vapor atoms reach the cooler substrate surface, they lose their energy and condense back into a solid state.

This isn't an instant process. The atoms nucleate at various points on the surface and grow into a continuous film layer by layer. The final properties of the film—its density, adhesion, and stress—are heavily influenced by the energy of the arriving atoms and the temperature of the substrate.

Understanding the Trade-offs: PVD vs. CVD

While PVD relies on physical processes, another common method, Chemical Vapor Deposition (CVD), uses chemical reactions. Understanding their differences is key to appreciating the theory behind PVD.

The PVD Advantage: Purity and Lower Temperatures

PVD is a direct physical transfer, meaning the deposited film can be exceptionally pure. Because it does not rely on high-temperature chemical reactions, it can be performed at much lower temperatures than many CVD processes. This makes PVD ideal for coating materials that cannot withstand high heat, such as plastics or certain alloys.

The CVD Advantage: Conformal Coating

CVD involves a chemical precursor gas that reacts on the substrate's surface to form the film. Because it is a gas-based reaction, it can coat all surfaces of a complex, three-dimensional object with a uniform film. PVD, being a "line-of-sight" process, struggles to evenly coat intricate shapes, shadows, and undercuts.

Film Characteristics

PVD films are typically very dense but can have high internal stresses due to the energetic nature of the deposition. In contrast, CVD offers excellent control over the film's crystalline structure and chemical composition by adjusting the precursor gases and process parameters, often resulting in films with low residual stress.

Making the Right Choice for Your Goal

Your choice between PVD and a chemical alternative depends entirely on the geometry of your part, the material you are depositing, and the properties you need in the final film.

- If your primary focus is coating a flat or simple surface at low temperatures: PVD is an excellent, high-purity choice for materials like optics, semiconductors, and tools.

- If your primary focus is uniformly coating a complex 3D part: CVD's ability to "wrap around" surfaces makes it the superior method for components with intricate geometries.

- If your primary focus is depositing a pure metal or simple compound: PVD methods like sputtering are highly controllable, repeatable, and a mature industry standard.

Ultimately, understanding that PVD is a line-of-sight physical transfer is the key to knowing when and how to apply it effectively.

Summary Table:

| PVD Stage | Key Process | Primary Method |

|---|---|---|

| 1. Vaporization | Solid source material is transformed into vapor. | Thermal Evaporation or Sputtering |

| 2. Transport | Vapor travels through a vacuum to the substrate. | Line-of-sight travel in a high-vacuum environment |

| 3. Condensation | Vapor condenses to form a solid thin film. | Nucleation and growth on the substrate surface |

Need a high-performance coating solution for your lab?

Understanding PVD theory is the first step. Implementing it effectively requires the right equipment. At KINTEK, we specialize in high-quality lab equipment, including PVD systems, to help you achieve precise, pure, and durable coatings for your research or production needs.

Our experts can help you select the perfect system for your specific application, whether you're working with flat substrates requiring a line-of-sight process or need to explore other coating technologies.

Contact KINTEK today to discuss your project and discover how our reliable PVD solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- How does the gas path control system influence the quality of silver nanocoatings? Mastering CVD Precision

- What is coated carbide tool? Boost Machining Performance with Advanced Coatings

- What is the sputtering process of magnetron deposition? A Guide to Efficient Thin-Film Coating

- What are the characteristics of thin films? Harnessing Unique Properties for Advanced Applications

- What are the disadvantages of conformal coating? Navigate Application, Rework, and Cost Challenges

- What is the effect of substrate temperature? Master Thin Film Quality & Adhesion

- What are the chemical deposition processes? A Guide to CVD, CSD, and Plating

- What is the difference between magnetron sputtering and DC sputtering? Boost Your Thin Film Deposition Rate & Quality