Preventive maintenance for a ball mill is a structured, proactive schedule of inspections, lubrication, adjustments, and component replacements designed to prevent unexpected breakdowns. This approach addresses the high-stress, abrasive environment in which ball mills operate by identifying and correcting potential issues before they lead to catastrophic failure and costly production halts.

The core objective of ball mill preventive maintenance is to shift from a reactive, failure-driven repair model to a proactive, reliability-focused strategy. This ensures maximum equipment uptime, enhances operational safety, and maintains consistent grinding efficiency.

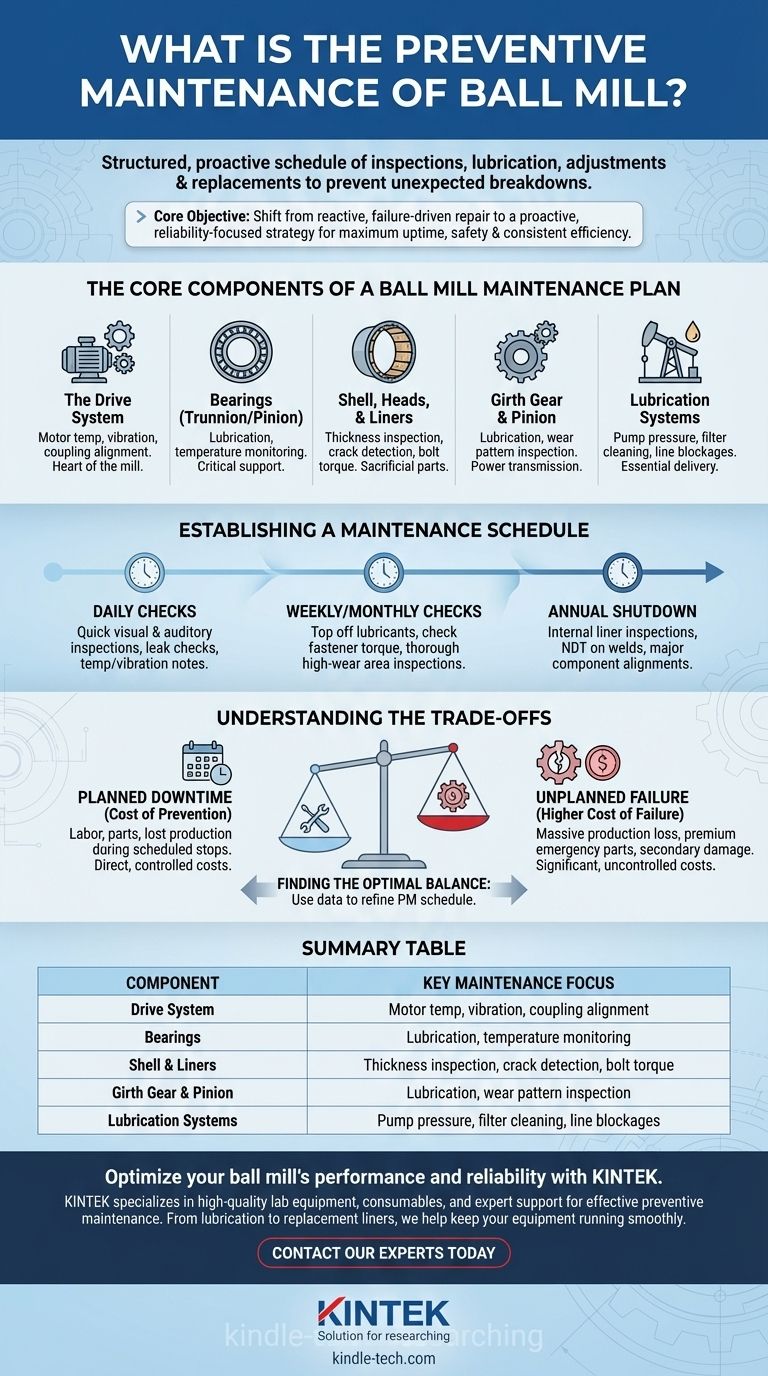

The Core Components of a Ball Mill Maintenance Plan

A successful preventive maintenance (PM) program is built on a systematic understanding of the machine's key systems. Each component has unique failure modes that require specific attention.

The Drive System (Motor, Couplings, and Gearbox)

The drive system is the heart of the mill. Its reliability is paramount.

Regular checks should include monitoring motor temperature and vibration. Ensure couplings are properly aligned and lubricated to prevent premature wear on connected components like the gearbox and pinion shaft.

Bearings (Trunnion and Pinion)

Bearings support the immense rotating load of the mill shell. Their failure is often catastrophic.

The most critical PM task is lubrication. Follow manufacturer specifications for the type, amount, and frequency of grease or oil application. Consistently monitor bearing temperatures, as a sudden increase is a primary indicator of impending failure.

Shell, Heads, and Liners

The mill shell and its internal liners are responsible for the grinding action and containment.

Liners are sacrificial wear parts. Regularly inspect them for thickness, cracks, or broken sections. Pay close attention to the liner bolts, as loose bolts can lead to shell damage and slurry leaks.

Girth Gear and Pinion

This massive gear set transmits power to the mill shell.

Proper lubrication is essential, typically using a specialized open-gear lubricant applied via an automated system. Regularly inspect the gear teeth for signs of pitting, scoring, or abnormal wear patterns, which can indicate misalignment.

Lubrication Systems

Many modern mills use automated systems to deliver oil and grease to critical points.

The PM for the lubrication system itself involves checking pump pressures, cleaning or replacing filters, and ensuring all delivery lines are intact and free of blockages. This ensures the actual components are receiving the protection they need.

Establishing a Maintenance Schedule: From Daily to Annually

An effective PM program layers tasks based on frequency and complexity. This distributes the workload and ensures constant vigilance.

Daily Operator Checks

These are quick, non-invasive inspections performed during operation. Operators should listen for unusual noises, visually check for leaks around seals, and note any abnormal temperatures or vibrations.

Weekly and Monthly Checks

These tasks are more detailed. They include topping off lubricant reservoirs, checking the torque on critical fasteners, and performing more thorough visual inspections of high-wear areas like feed and discharge chutes.

Annual Shutdown Inspection

This is the cornerstone of the PM program and requires significant downtime. During this outage, technicians perform internal inspections of liners, conduct non-destructive testing (NDT) on critical welds, and perform major component alignments.

Understanding the Trade-offs: Planned Downtime vs. Unplanned Failure

Implementing a PM program requires a commitment of resources, but it is a strategic investment in reliability.

The Cost of Prevention

Preventive maintenance has direct costs, including labor for inspections, the price of lubricants and replacement parts, and the lost production during planned shutdowns.

The Higher Cost of Failure

These planned costs are insignificant compared to an unplanned breakdown. A catastrophic failure results in massive production losses, often requires emergency parts procurement at a premium, and can cause secondary damage to other expensive components.

Finding the Optimal Balance

The goal is not to over-maintain the equipment. An effective program uses data from inspections, wear analysis, and oil sampling to refine the PM schedule. This ensures resources are focused where they are needed most, optimizing the balance between maintenance cost and equipment reliability.

Making the Right Choice for Your Goal

A robust PM program is not one-size-fits-all. It should be tailored to your operation's primary objectives.

- If your primary focus is maximizing uptime: Invest in predictive technologies like vibration analysis and thermal imaging to detect early-stage faults and precisely plan interventions.

- If your primary focus is controlling maintenance costs: Begin with a solid, time-based PM foundation covering all critical lubrication and inspection tasks to prevent the most common and expensive failures.

- If your primary focus is operational safety: Prioritize the structural integrity of the mill shell, regular inspection of all safety guards, and verification of emergency stop systems.

Ultimately, a well-executed preventive maintenance program transforms your ball mill from a potential liability into a predictable and reliable asset.

Summary Table:

| Component | Key Maintenance Focus |

|---|---|

| Drive System | Motor temperature, vibration, coupling alignment |

| Bearings | Lubrication, temperature monitoring |

| Shell & Liners | Thickness inspection, crack detection, bolt torque |

| Girth Gear & Pinion | Lubrication, wear pattern inspection |

| Lubrication Systems | Pump pressure, filter cleaning, line blockages |

Optimize your ball mill's performance and reliability with KINTEK.

A well-maintained ball mill is crucial for your lab's productivity and safety. KINTEK specializes in providing high-quality lab equipment, consumables, and expert support to help you implement an effective preventive maintenance program. From lubrication systems to replacement liners, we have the products and knowledge to keep your equipment running smoothly.

Don't let unexpected downtime disrupt your operations. Contact our experts today to discuss your specific ball mill needs and discover how KINTEK can enhance your lab's efficiency and reliability.

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials

- What are the main components of a ball mill? Optimize Your Grinding Process for Peak Performance

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What is the major limitation of ball mill? Ineffectiveness with soft, tacky, or fibrous materials