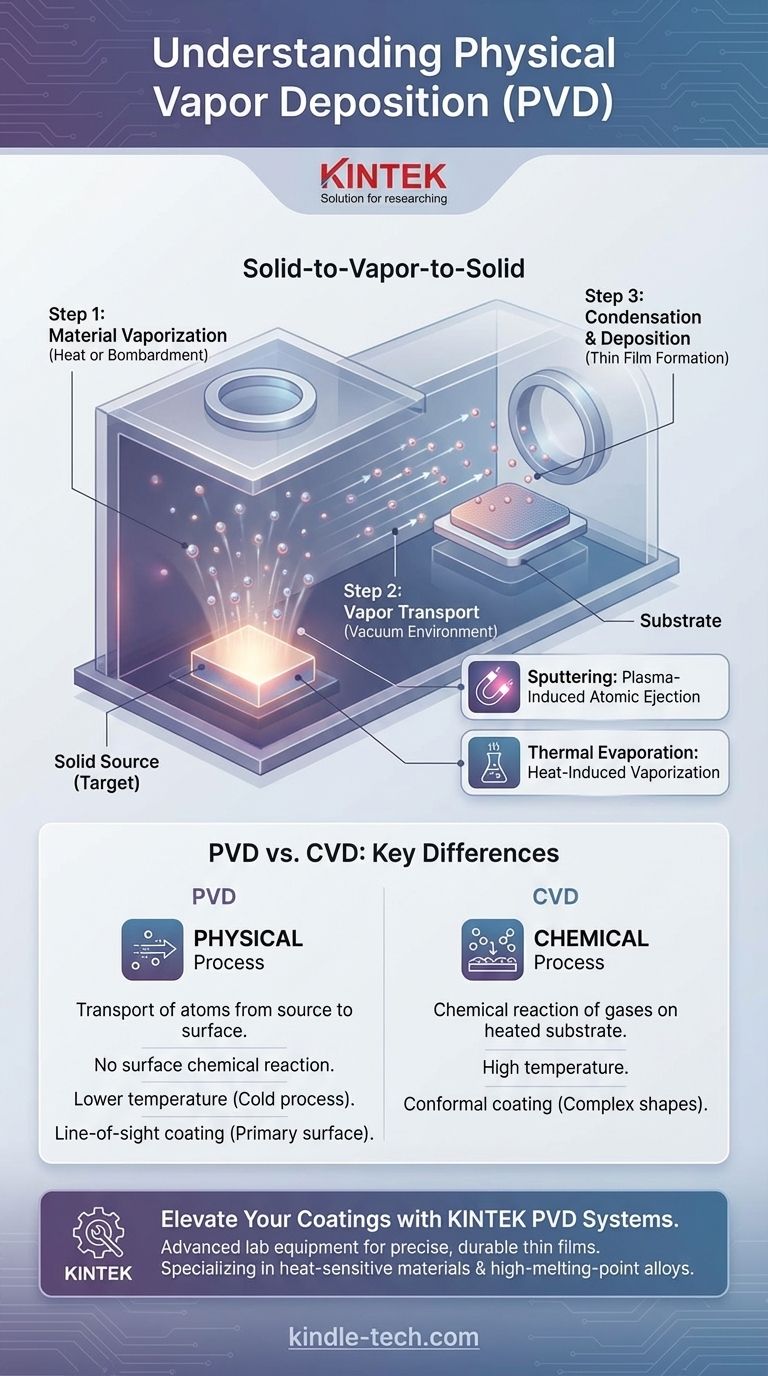

At its core, the principle of Physical Vapor Deposition (PVD) is a vacuum coating process that involves three fundamental steps: a solid material is converted into a vapor, this vapor travels across a vacuum chamber, and it condenses onto a target object (the substrate) to form a thin, high-performance film. It is a purely physical process, like spray-painting with individual atoms, rather than a chemical one.

The crucial distinction of PVD is that it physically transfers atoms from a source to a surface without inducing a chemical reaction on that surface. This "solid-to-vapor-to-solid" sequence allows for the deposition of materials that are difficult to handle otherwise, such as those with extremely high melting points.

The Fundamental PVD Mechanism: A Three-Step Journey

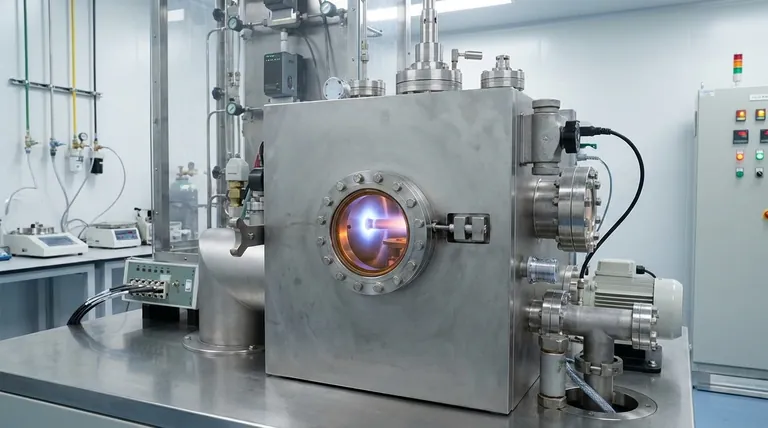

The entire PVD process takes place inside a vacuum chamber. This controlled environment is critical for ensuring the purity and quality of the final coating by preventing the vaporized atoms from reacting with particles in the air.

Step 1: Material Vaporization (The Source)

The process begins with a solid source material, often called a "target." This material is converted into a gaseous vapor phase through high-energy means.

This vaporization is typically achieved in one of two ways: by intense heating or by energetic particle bombardment.

Step 2: Vapor Transport (The Vacuum)

Once the atoms are liberated from the solid source, they travel in a relatively straight line through the vacuum chamber.

The vacuum ensures these atoms do not collide with air molecules or other contaminants, which would disrupt their path and contaminate the final film.

Step 3: Condensation and Deposition (The Substrate)

When the vaporized atoms reach the substrate (the object being coated), they condense back into a solid state.

This condensation builds up atom by atom, forming a thin, dense, and highly adherent film on the substrate's surface.

Common PVD Methods: Two Paths to the Same Goal

While the principle remains the same, the method of vaporizing the source material defines the specific type of PVD process.

Thermal Evaporation

This method involves heating the source material in the vacuum chamber until it boils and evaporates.

The resulting vapor cloud then rises and condenses on the cooler substrate, much like steam condensing on a cold mirror.

Sputtering

Sputtering uses a different approach. Instead of heat, a plasma is created, and positively charged ions from this plasma are accelerated to strike the negatively charged target material.

These high-energy collisions physically knock atoms off the surface of the target. These "sputtered" atoms are ejected with significant energy and deposit onto the substrate, forming a very dense and durable film. Magnetron sputtering uses powerful magnets to confine the plasma near the target, dramatically increasing the efficiency of this process.

Understanding the Trade-offs: PVD vs. CVD

To truly understand PVD, it is essential to contrast it with its chemical counterpart, Chemical Vapor Deposition (CVD).

The Core Distinction: Physical vs. Chemical

PVD is a physical process. Atoms are simply moved from a source and deposited onto a substrate. No fundamental chemical reaction occurs on the substrate's surface.

CVD is a chemical process. Precursor gases are introduced into a chamber where they react or decompose on a heated substrate to form the desired film. The coating itself is the product of this surface reaction.

Process Conditions

PVD is generally a lower-temperature "cold" process compared to the high temperatures often required to drive the reactions in CVD.

This makes PVD suitable for coating materials that cannot withstand high heat, such as certain plastics or tempered alloys.

Coating Characteristics

Because PVD is a "line-of-sight" process, the coating is primarily deposited on surfaces directly facing the source material.

CVD, which uses gases, can often provide a more uniform (conformal) coating on complex shapes and internal surfaces, as the gases can flow and react anywhere the temperature is sufficient.

Making the Right Choice for Your Goal

Selecting the correct deposition technology depends entirely on the material properties and the geometry of the part being coated.

- If your primary focus is coating heat-sensitive materials or alloys with extremely high melting points: PVD, particularly sputtering, is often the superior choice due to its physical mechanism and lower substrate temperatures.

- If your primary focus is creating a perfectly uniform coating on complex, non-flat surfaces: CVD may be more effective, as the reactive gases can conform to intricate geometries better than a line-of-sight physical process.

Understanding this fundamental difference between physical transport and chemical reaction is the key to selecting the ideal thin-film coating technology for any application.

Summary Table:

| PVD Principle Step | Key Action | Key Requirement |

|---|---|---|

| 1. Vaporization | Solid source material is converted into a vapor. | High energy (heat or particle bombardment). |

| 2. Transport | Vaporized atoms travel through the chamber. | High vacuum environment. |

| 3. Condensation | Vapor condenses on the substrate, forming a thin film. | Cooler substrate surface. |

Need a high-performance PVD coating for your application? KINTEK specializes in advanced lab equipment, including PVD systems, to help you achieve precise, durable thin films. Whether you're working with heat-sensitive materials or require high-melting-point coatings, our expertise ensures optimal results. Contact our experts today to discuss your specific laboratory needs and find the perfect solution!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition