At its core, Spark Plasma Sintering (SPS) is an advanced consolidation technique that uses simultaneous high pressure and a large, pulsed direct current (DC) to transform powders into a dense, solid material. Unlike conventional furnaces that heat materials from the outside in, SPS passes electricity directly through the powder, generating intense internal heat and localized plasma between particles. This unique combination achieves full densification in a fraction of the time required by traditional methods.

Spark Plasma Sintering should not be viewed as just a faster heating method. It is a field-assisted process where the combination of pressure, Joule heating, and plasma effects fundamentally alters and accelerates the material bonding process, enabling outcomes that are often impossible with conventional sintering.

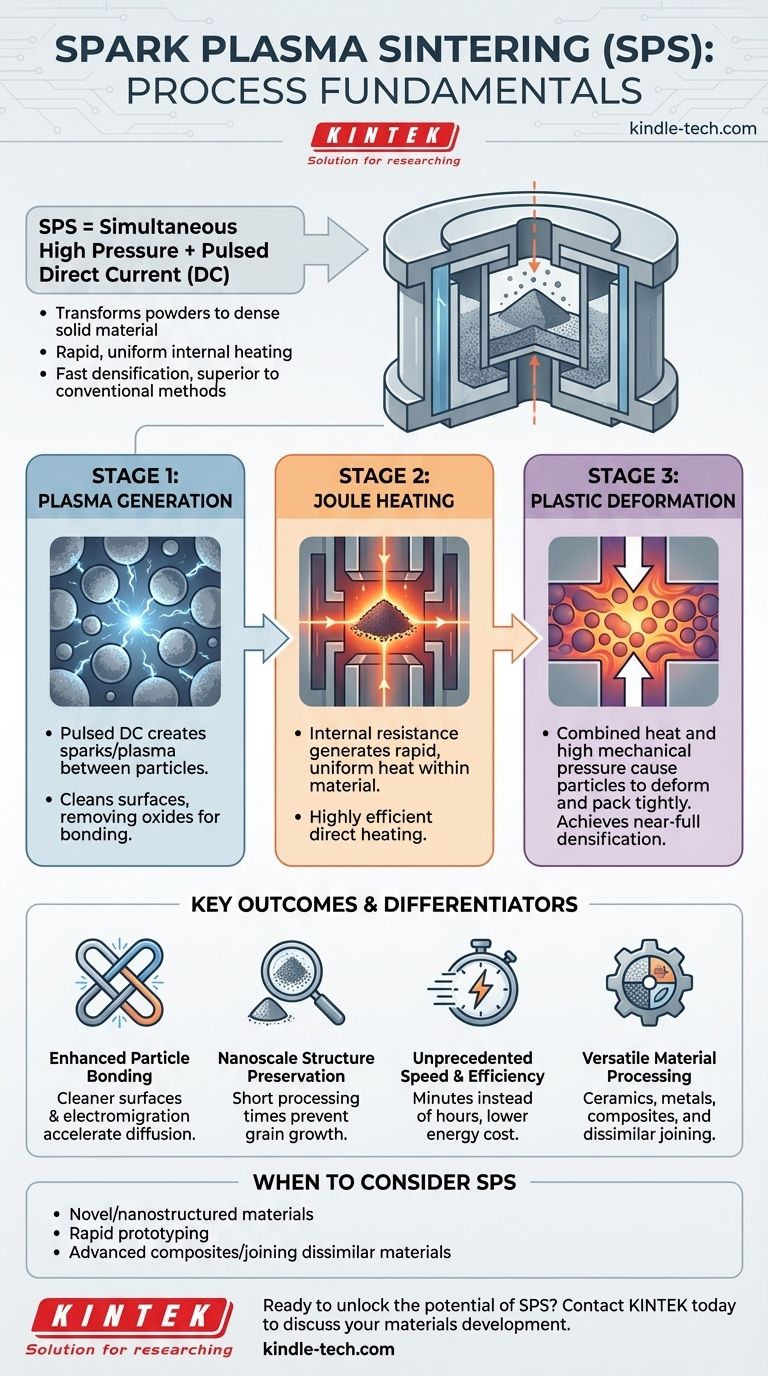

The Three Core Stages of the SPS Process

The rapid consolidation achieved in SPS is a result of three distinct but overlapping physical stages. Understanding this sequence is key to grasping how the technology works.

Stage 1: Plasma Generation

Initially, the pulsed DC current is applied to the loosely packed powder. The electrical current seeks the path of least resistance, arcing across the tiny gaps between individual powder particles.

This discharge creates instantaneous, localized high-temperature zones, generating sparks or plasma. This plasma cleans the surfaces of the powder particles, removing oxides and contaminants that would otherwise inhibit bonding.

Stage 2: Joule Heating

As the current flows through the powder and the conductive tooling, it generates rapid and uniform heat due to electrical resistance. This phenomenon is known as Joule heating.

Because the heat is generated within the material itself, the heating rates are exceptionally high. This direct heating mechanism is fundamentally more efficient and faster than relying on slow thermal conduction from external heating elements in a traditional furnace.

Stage 3: Plastic Deformation

Simultaneously with the heating, a high mechanical pressure is applied. The combination of intense heat and pressure softens the material, causing the particles to deform and flow.

This plastic deformation, aided by enhanced diffusion from the electrical effects, allows the particles to rearrange and pack together tightly, eliminating the voids between them and resulting in a highly dense final component.

What Makes SPS Fundamentally Different?

The advantages of SPS stem directly from its unique physical mechanisms, which offer a level of control and speed that conventional methods cannot match.

Enhanced Particle-to-Particle Bonding

The spark-induced plasma plays a critical role beyond just heating. By cleaning particle surfaces, it creates pristine contact points that are highly active and ready for bonding.

Furthermore, effects like electromigration (the movement of atoms due to the electric current) accelerate material diffusion at the particle boundaries. This allows strong bonds to form at lower overall temperatures and in much shorter times.

Preservation of Nanoscale Structures

In advanced materials science, preserving a fine-grained or nanostructured microstructure is often critical to achieving desired properties. Long exposure to high temperatures in conventional sintering causes grains to grow, destroying these delicate features.

Because SPS operates at lower temperatures and for drastically shorter times—often just a few minutes—it can successfully consolidate nanomaterials while preserving their original refined microstructure.

Key Outcomes of the SPS Method

The fundamentals of the process directly translate into tangible, high-impact advantages for materials processing.

Unprecedented Speed and Efficiency

By directly heating the component, SPS reduces processing cycles from many hours or even days to just a few minutes. This dramatic reduction in time, combined with lower sintering temperatures, significantly cuts down on energy consumption and operational costs.

Superior Material Properties

The ability to achieve near-full densification while preventing grain growth results in materials with superior mechanical strength, hardness, and other performance characteristics. The structure is uniform and dense throughout the component.

Versatile Material Processing

SPS is effective for a wide range of materials, including ceramics, refractory metals, amorphous materials like glass, and composites. It also enables the unique capability of joining dissimilar materials, such as a ceramic to a metal, creating strong, functional bonds that are difficult to achieve otherwise.

When to Consider Spark Plasma Sintering

Applying this knowledge to your work depends on your specific material and performance goals.

- If your primary focus is processing novel or nanostructured materials: SPS is the superior choice for preserving fine-grained microstructures that are essential for high-performance applications.

- If your primary focus is rapid prototyping and material development: The extremely short cycle times allow you to iterate and test new material compositions and formulations with unmatched speed.

- If your primary focus is creating advanced composites or joining dissimilar materials: SPS provides a unique capability for consolidating multi-material systems and creating strong bonds between materials like ceramics and metals.

Ultimately, Spark Plasma Sintering provides a powerful tool for manufacturing advanced materials that were previously out of reach.

Summary Table:

| Stage | Key Mechanism | Primary Outcome |

|---|---|---|

| Plasma Generation | Pulsed current creates sparks/plasma between particles | Cleans particle surfaces, enabling strong bonding |

| Joule Heating | Current generates rapid, internal heat within the powder | Fast, uniform heating to sintering temperature |

| Plastic Deformation | Combined heat and pressure cause particles to deform and flow | Elimination of voids, achieving near-full densification |

Ready to unlock the potential of Spark Plasma Sintering in your lab?

KINTEK specializes in advanced lab equipment, including SPS systems, to help you rapidly consolidate novel materials, preserve nanoscale structures, and develop high-performance composites. Our expertise supports researchers and engineers in achieving superior material properties with unmatched efficiency.

Contact KINTEK today to discuss how our sintering solutions can accelerate your materials development.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Graphite Vacuum Continuous Graphitization Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What microstructural advantages does PCAS offer over HPS for NiAl-Al2O3? Unlock Superior Grain Refinement

- What is the spark plasma sintering method? Achieve Rapid, High-Density Material Consolidation

- What is hot isostatic pressing? Achieve Full Density and Superior Material Performance

- How does a vacuum hot pressing sintering furnace densify CoCrFeNi alloys? Achieve 98%+ Density and Pure Microstructures

- How does a hot isostatic press (HIP) enhance Al-LLZ lithium garnet performance? Achieving 98%+ Density and Clarity

- How does a vacuum hot press sintering furnace contribute to TiCN-reinforced Ti-Fe composites? Achieve 99% Densification

- What is spark plasma sintering of polymers? Rapidly Create Dense, High-Performance Materials

- How does a high vacuum environment contribute to the hot pressing of Ruthenium? Enhance Purity and Density