At its core, the bell annealing furnace process is a multi-stage heat treatment method designed for efficiency and precision. The material, often steel or aluminum coils, is stacked on a stationary base and covered with a sealed inner retort. A larger, movable "bell" containing heating elements is lowered over the assembly, which is then purged of oxygen and filled with a protective gas atmosphere for the heating and cooling cycles.

The defining characteristic of the bell annealing process is not just the heating and cooling, but its use of a movable heating bell and a controlled protective atmosphere. This design maximizes furnace uptime and prevents material oxidation, ensuring consistent, high-quality results in a batch-processing environment.

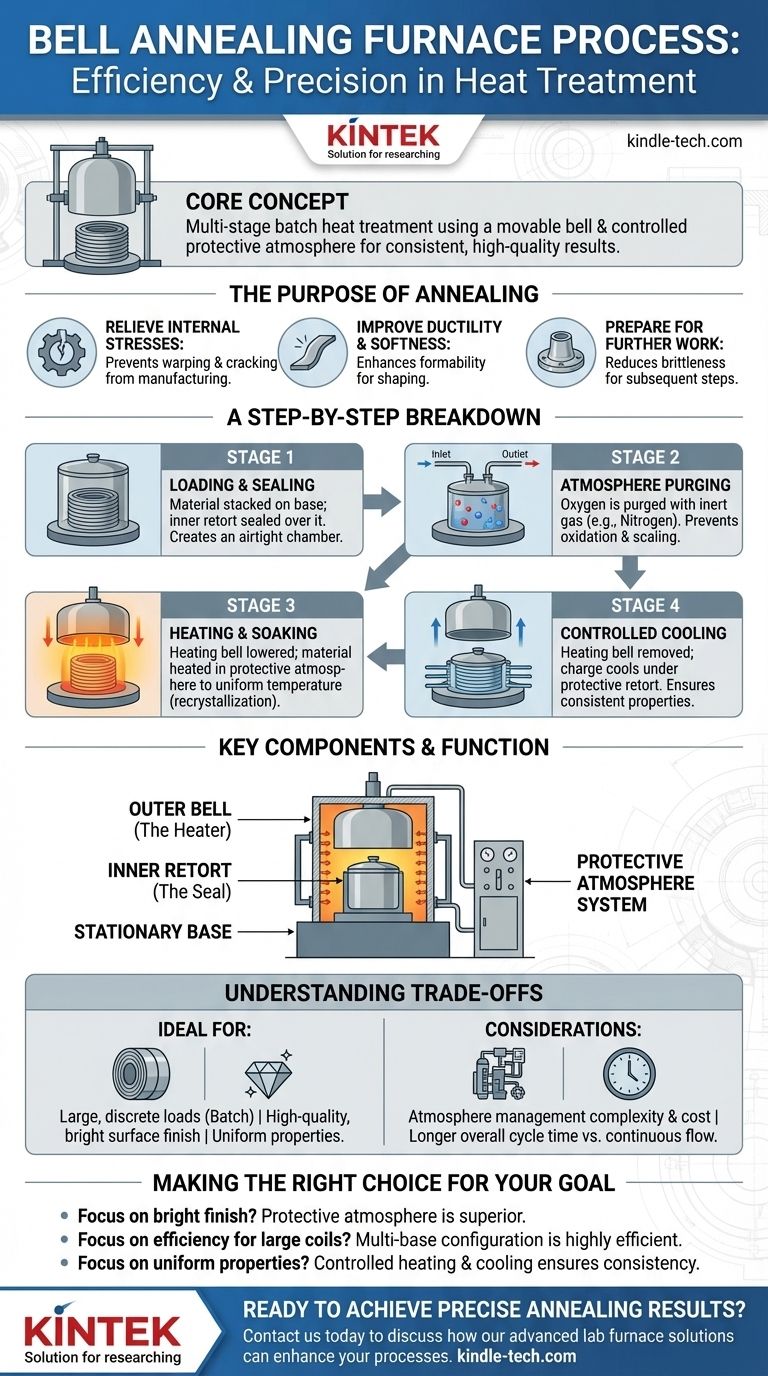

The Purpose of Bell Annealing

Annealing is a heat treatment process that alters a material's microstructure to achieve specific desirable properties. A bell furnace is simply a highly effective tool for carrying out this process.

Relieving Internal Stresses

Manufacturing processes like rolling, drawing, or machining introduce significant internal stresses into materials. Annealing heats the material to a point where these stresses can relax, preventing future warping or cracking.

Improving Ductility and Softness

The primary goal of many annealing operations is to make a material softer and more ductile (easier to bend and shape). This is achieved by heating it above its recrystallization temperature, which allows new, strain-free grains to form in its structure.

Preparing Material for Further Work

By making the material less brittle and more formable, annealing prepares it for subsequent manufacturing steps like stamping, deep drawing, or complex bending without the risk of fracture.

A Step-by-Step Breakdown of the Process

The bell furnace process is a carefully orchestrated sequence designed for control and repeatability.

Stage 1: Loading and Sealing

First, the charge (the material to be treated) is carefully stacked onto a stationary hearth or base. A thin, sealed inner cover, often called a retort, is then placed over the charge, creating an airtight container.

Stage 2: Atmosphere Purging

Before heating, any oxygen inside the retort must be removed to prevent oxidation and scaling on the material's surface. The air is purged with an inert gas, typically nitrogen, until oxygen levels are negligible.

Stage 3: Heating and Soaking

The movable outer bell, which contains the heating elements, is lowered over the sealed retort. The furnace heats the charge in a controlled protective atmosphere (often a mix of hydrogen and nitrogen). The material is held at a specific temperature for a set period, known as "soaking," to ensure the entire charge reaches a uniform temperature and the desired microstructural changes occur.

Stage 4: Controlled Cooling

Once the soaking period is complete, the outer heating bell is lifted and moved to another base to begin heating a new charge. The original charge, still covered by the inner retort and protective atmosphere, is left to cool. This cooling is often accelerated by blowing air over the outside of the retort, allowing for a controlled, consistent cooling rate that is crucial for achieving the final material properties.

Key Components and Their Function

Understanding the hardware reveals why the process is so effective.

The Stationary Base

This is the foundation where the material is loaded. A single heating bell typically serves multiple bases, allowing one charge to be cooled or unloaded while another is being heated, drastically improving operational efficiency.

The Inner Retort (The Seal)

This sealed steel container is the most critical component for quality. Its sole purpose is to contain the protective atmosphere and isolate the material from outside air throughout the entire heating and cooling cycle.

The Outer Bell (The Heater)

This is the actual furnace. It's an insulated shell lined with heating elements that can be moved from one base to another. This mobility is the key to the system's high throughput and efficiency.

The Protective Atmosphere System

This system manages the precise mixture and flow of gases like nitrogen and hydrogen. It is responsible for purging oxygen and maintaining a de-oxidizing environment during the cycle, which is essential for a clean, bright surface finish on the final product.

Understanding the Trade-offs

While highly effective, the bell furnace process has specific characteristics that make it suitable for some applications but not others.

Batch Processing vs. Continuous Flow

A bell furnace is fundamentally a batch process. This is ideal for treating large, discrete loads like coils of steel but is less efficient than a continuous furnace for processing a constant stream of individual parts.

Atmosphere Management Complexity

The reliance on a controlled protective atmosphere adds complexity and cost. It requires precise gas control systems, safety protocols (especially when using hydrogen), and diligent monitoring to prevent leaks in the retort seals.

Cycle Time

While moving the heating bell improves efficiency, the overall cycle time for a single charge—including purging, heating, soaking, and cooling—can be lengthy. This must be factored into production planning.

Making the Right Choice for Your Goal

Selecting the right process depends entirely on your material and production requirements.

- If your primary focus is a high-quality, bright surface finish: The protective atmosphere of a bell furnace is superior, as it prevents oxidation and discoloration.

- If your primary focus is operational efficiency for large coils or stacks: The multi-base configuration allows for near-continuous heating, making it a highly efficient batch process.

- If your primary focus is achieving uniform material properties in a large charge: The controlled heating and slow, protected cooling of the bell furnace process ensures consistency throughout the entire stack.

Ultimately, the bell annealing process provides an exceptional level of control over the material's environment, ensuring predictable and high-quality metallurgical results.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Loading & Sealing | Material stacked on base; inner retort sealed over it. | Creates an airtight chamber for the protective atmosphere. |

| 2. Atmosphere Purging | Oxygen is purged with inert gas (e.g., Nitrogen). | Prevents oxidation and scaling on the material surface. |

| 3. Heating & Soaking | Heating bell is lowered; material is heated in a protective atmosphere. | Achieves uniform temperature for microstructural changes (recrystallization). |

| 4. Controlled Cooling | Heating bell is removed; charge cools under the protective retort. | Ensures consistent material properties and prevents warping. |

Ready to achieve precise, high-quality annealing results in your lab?

KINTEK specializes in providing robust laboratory equipment, including advanced furnace solutions. Our expertise ensures you get the right tools for controlled heat treatment processes, helping you improve material ductility, relieve internal stresses, and achieve bright, oxidation-free finishes.

Contact us today via our contact form to discuss how our lab equipment can enhance your annealing processes and deliver consistent, reliable results for your specific materials and production goals.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the four types of heat treating processes? Master Annealing, Normalizing, Hardening, and Tempering

- What is a vacuum heat treatment furnace? The Ultimate Guide to Controlled Atmosphere Processing

- Why do you heat treat in a vacuum? Achieve Perfect Surface Finish and Material Integrity

- What are the parts of a vacuum furnace? A Guide to the 5 Core Systems

- What are the five basic heat treatment processes of metals? Master Annealing, Hardening & More