At its core, the Hot Isostatic Pressing (HIP) heat treatment is a process that simultaneously applies high temperature and uniform, high-pressure gas to a material. This combination effectively "squeezes" out internal defects like microscopic pores (porosity), creating a fully dense component with superior mechanical properties. The key steps involve loading the part into a sealed vessel, heating it, pressurizing the vessel with an inert gas like argon, holding it at these conditions, and then cooling it back down.

The central purpose of HIP is not merely to heat a material, but to use heat to make it pliable enough for high-pressure inert gas to physically collapse and eliminate internal voids. This turns a potentially flawed component into a solid, reliable one.

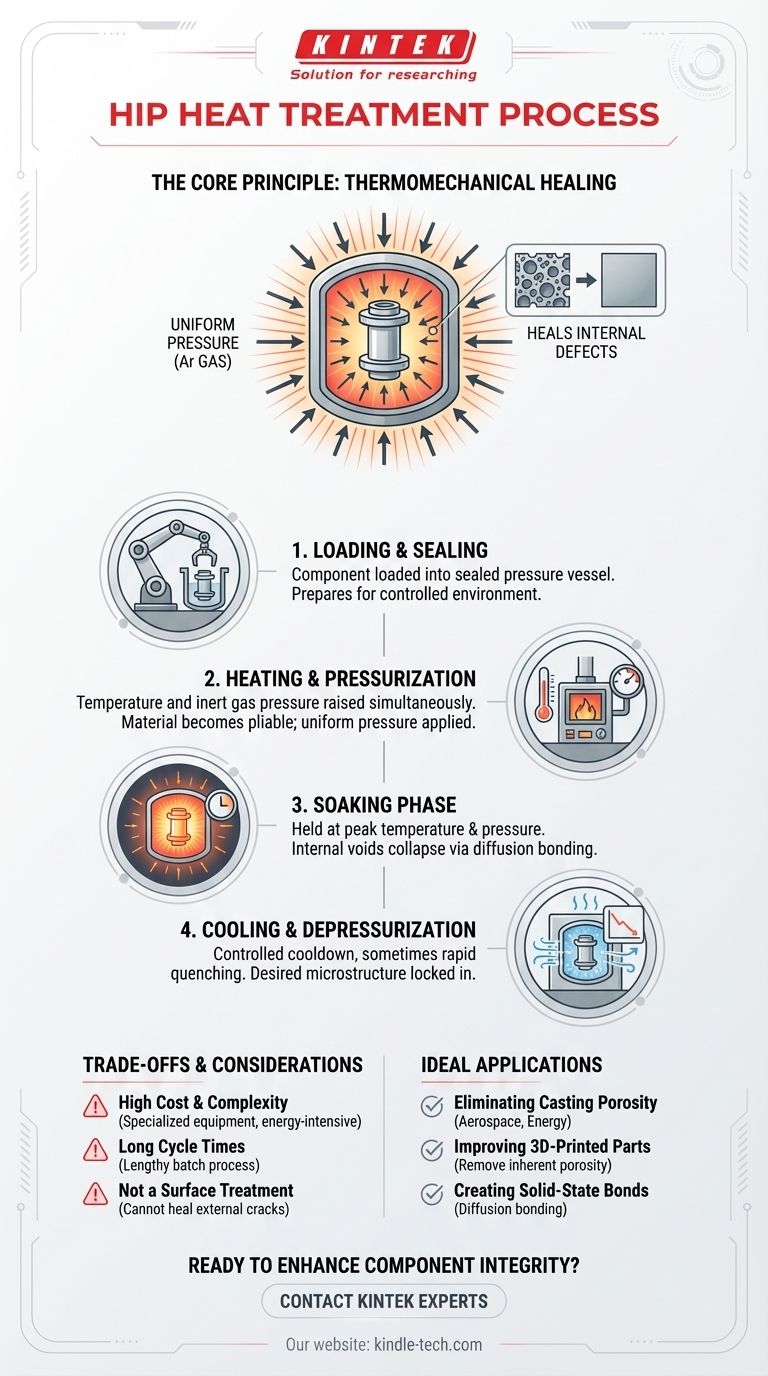

The Core Principle: How HIP Heals Materials

To truly understand the HIP process, you must recognize it as a thermomechanical treatment. The heat and pressure work in perfect concert, each playing a critical role in transforming the material's internal structure.

The Role of High Temperature

The first step is heat. Raising the material's temperature well into its plastic deformation range makes it soft and malleable. This thermal energy allows the atoms within the material to move more freely, a necessary precondition for healing defects.

The Function of Isostatic Pressure

While the material is hot and soft, an inert gas (typically argon) is pumped into the sealed vessel, creating immense pressure. The term isostatic is key—it means the pressure is applied equally from all directions. This uniform force gently squeezes the component, collapsing any internal pores, voids, or micro-cracks.

The Importance of Inert Gas

Using an inert gas like argon is non-negotiable. At these high temperatures, a reactive gas like oxygen would cause severe oxidation and damage the component. Argon serves as a clean, non-reactive medium to transmit the pressure without altering the material's chemistry.

A Step-by-Step Breakdown of the HIP Cycle

While specific parameters vary by material and application, every HIP cycle follows a distinct and controlled sequence that can last from 8 to 12 hours or more.

Loading and Sealing

Components are carefully loaded into the furnace section of the HIP pressure vessel. Once loaded, the vessel is hermetically sealed to contain the extreme pressures and temperatures that will be applied.

Heating and Pressurization

The internal furnace begins to heat the components according to a predefined thermal profile. Simultaneously, argon gas is pumped into the vessel, raising the internal pressure to the target level. Heat and pressure rise together in a controlled manner.

The Soaking Phase

This is the main treatment phase where the material is "soaked" at a specific peak temperature and pressure. During this hold time, the combination of heat and isostatic force forces internal void surfaces to bond together on an atomic level, a process known as diffusion bonding. This is what eliminates the porosity.

Cooling and Depressurization

After the soaking period, the cycle concludes with a controlled cooling phase. Some advanced HIP units can perform pressurized rapid cooling, which acts as a quenching step. This can lock in a desirable microstructure, combining the benefits of HIP with a heat treatment in a single cycle.

Understanding the Trade-offs and Considerations

HIP is an incredibly powerful process, but it is not a universal solution. Understanding its limitations is critical for its effective application.

High Cost and Complexity

HIP units are highly specialized and expensive pieces of equipment, requiring a pressure vessel capable of withstanding extreme conditions. The process is energy-intensive and consumes large amounts of argon gas, making it a costly step reserved for high-value components.

Long Cycle Times

As noted, a typical HIP cycle is a lengthy batch process. This long duration must be factored into production timelines and costs, as it can be a significant bottleneck compared to other heat treatment methods.

Not a Surface Treatment

HIP is designed to eliminate internal defects. It cannot heal cracks or voids that are open to the surface of the part. The pressurized gas would simply enter the crack from the outside, equalizing the pressure and preventing it from being closed.

Making the Right Choice for Your Goal

Applying HIP should be a deliberate decision driven by a specific engineering need.

- If your primary focus is eliminating casting porosity: HIP is the industry-standard solution for increasing the density and fatigue life of critical cast components in aerospace and energy applications.

- If your primary focus is improving 3D-printed metal parts: HIP is a vital post-processing step to remove the inherent porosity from additive manufacturing, significantly improving the part's strength and reliability.

- If your primary focus is creating solid-state bonds: The process is exceptionally effective for diffusion bonding dissimilar materials or consolidating metal powders into fully dense, near-net-shape parts.

Ultimately, understanding the HIP process empowers you to specify a manufacturing step that transforms good components into exceptional ones.

Summary Table:

| HIP Process Step | Key Function | Outcome |

|---|---|---|

| Loading & Sealing | Component is placed in a sealed pressure vessel. | Prepares for controlled environment. |

| Heating & Pressurization | Temperature and inert gas pressure are raised simultaneously. | Material becomes pliable; pressure is applied uniformly. |

| Soaking Phase | Held at peak temperature and pressure. | Internal voids collapse via diffusion bonding. |

| Cooling & Depressurization | Controlled cooldown, sometimes with rapid quenching. | Desired microstructure is locked in; cycle completes. |

Ready to enhance the integrity and performance of your critical components?

KINTEK specializes in advanced lab equipment and consumables, serving the precise needs of laboratories in aerospace, additive manufacturing, and energy sectors. The HIP process is a cornerstone of creating reliable, high-value parts.

Let our experts help you determine if HIP is the right solution for your application. We provide the technology and support to eliminate porosity and achieve superior material properties.

Contact our team today for a consultation and discover how KINTEK can support your quality and innovation goals.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Cylindrical Press Mold with Scale for Lab

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

People Also Ask

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process