At its core, the purpose of radiation is to transfer heat energy through electromagnetic waves, a unique process that does not require any physical medium. This is how the sun's energy travels through the vacuum of space to warm the Earth and how specialized industrial equipment can heat materials without ever touching them.

While conduction and convection depend on physical contact or fluid movement, radiation's unique purpose is to bypass these constraints. This allows it to transfer thermal energy across a vacuum, through air, or through transparent materials, making it a fundamental force in both nature and technology.

The Fundamental Mechanism: How Radiation Works

To understand the purpose of radiation, we must first understand its distinct mechanism. It operates on principles entirely different from other forms of heat transfer.

Heat as Electromagnetic Waves

All matter with a temperature above absolute zero emits thermal energy. This energy is released not as moving atoms, but as electromagnetic waves (photons), part of the same spectrum that includes visible light, microwaves, and X-rays.

For heat transfer, we are primarily concerned with the infrared portion of this spectrum. A hotter object simply radiates more energetic and a higher quantity of these waves.

No Medium Required

This is the defining characteristic of radiation. Conduction requires direct molecular contact (a hot pan handle), and convection requires the movement of a fluid like air or water.

Radiation needs neither. The energy is encoded in the electromagnetic waves themselves, which can travel unimpeded through the vacuum of space or transparent media like glass.

Governed by Temperature and Surface

The rate of heat transfer is not linear. According to the Stefan-Boltzmann law, the energy an object radiates is proportional to the fourth power of its absolute temperature (T⁴).

This means a small increase in an object's temperature leads to a much larger increase in the amount of heat it radiates. The object's surface finish—its color, texture, and coating—also plays a critical role in how efficiently it emits and absorbs this energy.

Understanding the Trade-offs and Key Properties

Leveraging radiation effectively requires understanding its unique strengths and limitations. It is not a universal solution but a specialized tool for specific thermal problems.

Surface Properties are Critical

A material's ability to emit energy is called emissivity, and its ability to absorb it is absorptivity. A matte black object has high emissivity and absorptivity, making it excellent at both radiating and absorbing heat.

Conversely, a shiny, polished surface has low emissivity and absorptivity. This is why emergency space blankets are reflective—to minimize heat loss from the body via radiation.

Line-of-Sight Dependency

Radiant energy travels in straight lines, just like light. If an object is not in the direct line of sight of the heat source, it will not be heated directly.

This creates a "shadowing" effect, which is a major design constraint. In contrast, convection can transfer heat around corners by warming the air that circulates through a space.

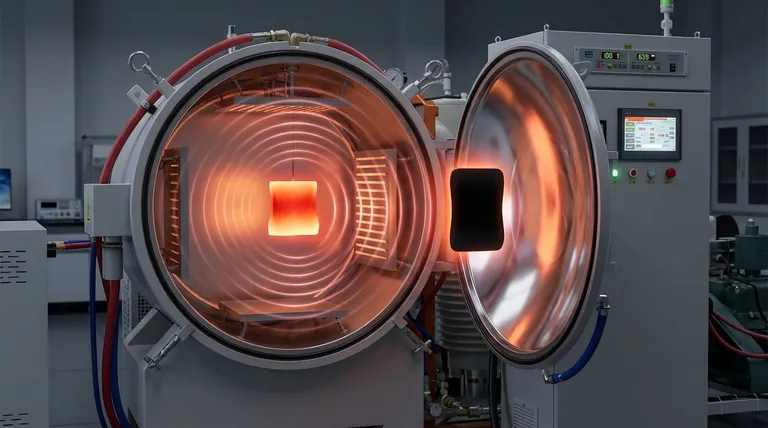

Targeted, Non-Contact Heating

Because radiation does not require a medium, it is the basis for all non-contact heating technologies. Infrared lamps can cure paint on a car body or process food without physical contamination.

This allows for precise, clean, and often rapid heating in controlled manufacturing environments, as hinted at by heat treatment processes.

When to Leverage Radiative Heat Transfer

Your choice of heat transfer method must align with the specific constraints and goals of your application.

- If your primary focus is transferring heat in a vacuum: Radiation is your only viable option, making it essential for spacecraft thermal management and astronomical calculations.

- If your primary focus is rapid, non-contact heating: Radiative methods like infrared heaters provide precise control for industrial processes like drying, curing, or semiconductor manufacturing.

- If your primary focus is passive thermal management: Manipulating surface properties (emissivity) through coatings and finishes is a key strategy for controlling heat gain and loss in buildings, electronics, and clothing.

Mastering the principles of radiation gives you a powerful and unique tool for solving thermal challenges that conduction and convection cannot address.

Summary Table:

| Key Property | How It Affects Radiation |

|---|---|

| Medium Required | None (works in a vacuum) |

| Speed of Transfer | Speed of light |

| Dependence | Line-of-sight only |

| Governing Law | Stefan-Boltzmann (T⁴) |

| Surface Impact | High (emissivity/absorptivity critical) |

Ready to leverage radiation for your lab's heating needs? KINTEK specializes in advanced lab equipment that utilizes radiative heat transfer for precise, non-contact processes like drying, curing, and heat treatment. Our expertise ensures you get the right tools for applications in vacuums or controlled environments where conduction and convection fall short. Contact us today to discuss how our solutions can enhance your laboratory's efficiency and capabilities!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the function of a double-layer water-cooled stainless steel chamber? Key to Ultrafine Magnesium Powder Production

- Why is a high-temperature furnace required for the solution treatment of Cr-Ni-Ti stainless steel? Optimize Swaging.

- What are the two types of annealing? Full vs. Process Annealing Explained

- What is debinding in 3D printing? The Essential Step for Strong Metal & Ceramic Parts

- What is the purpose of using a vacuum oven for extended drying periods? Optimize Composite Polymer Electrolyte Prep

- What is the difference between annealing and process annealing? A Guide to Choosing the Right Heat Treatment

- What is the hazard of heat treatment? Uncontrolled Processes Risk Product Failure and Safety

- What is the temperature of a calcination furnace? Unlocking the Key to Your Material's Transformation