At its core, sintering is a manufacturing process that transforms a powder into a solid, dense object using heat and pressure. Unlike casting, which involves completely melting the material, sintering heats the powder to a point just below its melting temperature, causing the individual particles to fuse and bond together into a single, strong piece.

Sintering is not just a heating method; it is a precise engineering technique for creating strong, complex parts from powder. This approach unlocks manufacturing possibilities for materials that are otherwise difficult or impossible to process through traditional melting and casting.

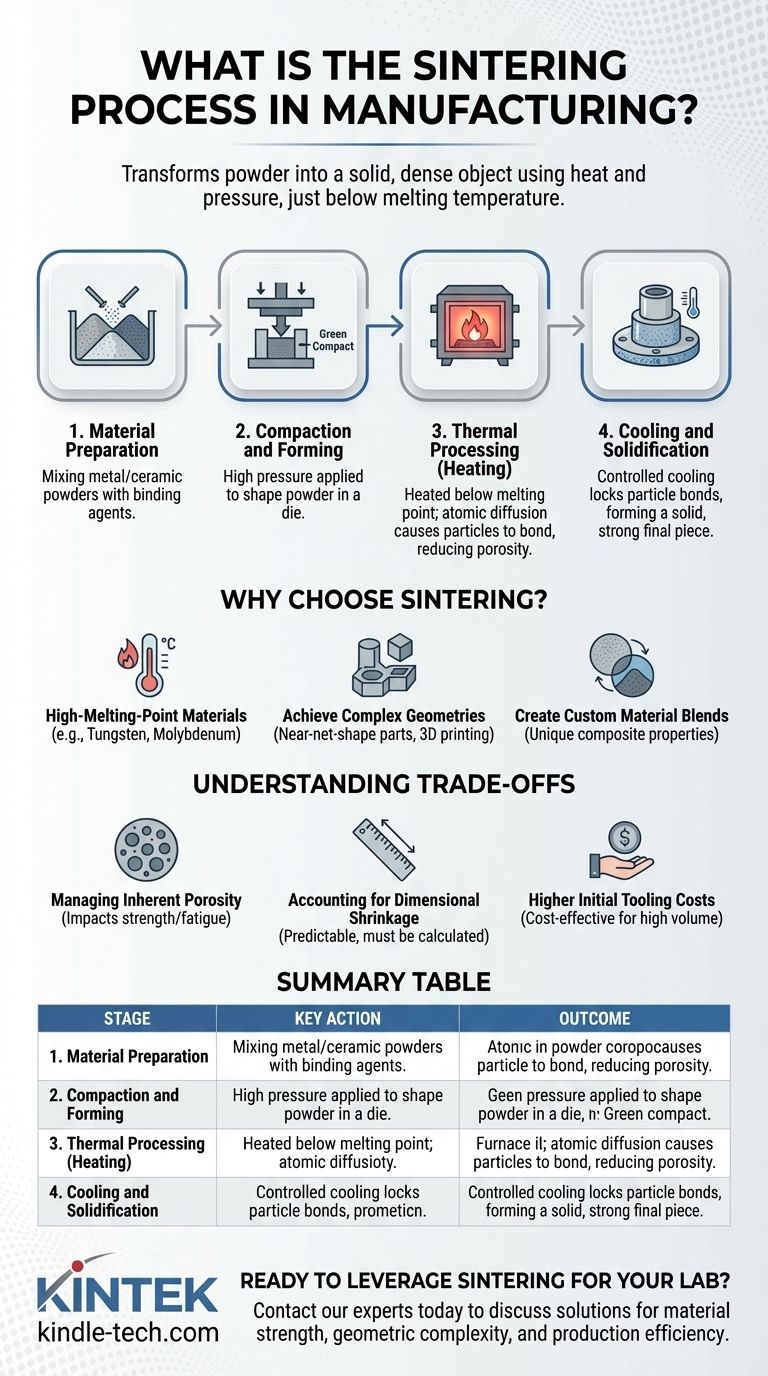

The Four Core Stages of Sintering

The sintering process can be understood as a sequence of four distinct stages, each critical to the final properties of the component.

Stage 1: Material Preparation

Before any heating occurs, the base material—typically a fine metal, ceramic, or plastic powder—is prepared. This often involves mixing the primary powder with other elements, such as alloys or binding agents, to achieve the desired final composition and aid in the forming process.

Stage 2: Compaction and Forming

The prepared powder is placed into a die, mold, or build chamber. High pressure is then applied to compact the powder into the desired shape. This initial, fragile object is often referred to as a "green compact."

Stage 3: Thermal Processing (Heating)

The green compact is carefully placed into a controlled-atmosphere furnace. It is heated to a specific temperature below the material's melting point. At this high temperature, a process called atomic diffusion occurs, causing the particles to bond at their contact points, reducing porosity and significantly increasing the part's density and strength.

Stage 4: Cooling and Solidification

After holding the part at the sintering temperature for a set time, it is cooled in a controlled manner. This final stage locks the newly formed particle bonds in place, resulting in a solid, unified mass with the intended mechanical properties.

Why Choose Sintering Over Traditional Methods?

Sintering is not just an alternative to casting; it is a superior solution for specific engineering challenges.

Working with High-Melting-Point Materials

Sintering is exceptionally valuable for processing refractory metals like tungsten and molybdenum. These materials have extremely high melting points, making them impractical or impossible to melt and cast with conventional equipment.

Achieving Complex Geometries

The process allows for the creation of intricate, near-net-shape parts that would require extensive and costly machining if made another way. Additive manufacturing, or metal 3D printing, heavily relies on sintering (e.g., Direct Metal Laser Sintering) to build complex parts layer by layer directly from powder.

Creating Custom Material Blends

Because it starts with powders, sintering allows engineers to create unique composite materials. Metals can be blended with ceramics or other elements to produce parts with specialized properties (e.g., cermets) that cannot be formed by melting.

Understanding the Trade-offs and Limitations

While powerful, sintering has practical considerations that must be managed for successful outcomes.

Managing Inherent Porosity

Although sintering dramatically increases density, it can be difficult to eliminate all microscopic pores between the original powder particles. This residual porosity can impact the ultimate strength and fatigue life of the component compared to a fully wrought or cast part.

Accounting for Dimensional Shrinkage

As the powder compact densifies during heating, the part will shrink. This shrinkage is predictable but must be precisely calculated and accounted for in the initial design of the mold and the green compact to ensure the final part meets dimensional tolerances.

Higher Initial Tooling Costs

For press-and-sinter operations, the cost of creating the high-precision dies and molds for compaction can be substantial. This typically makes the process most cost-effective for medium-to-high volume production runs where the tooling cost can be amortized.

Making the Right Choice for Your Goal

Selecting the right manufacturing process depends entirely on your material and design objectives.

- If your primary focus is working with high-temperature materials like tungsten or ceramics: Sintering is often the most practical, and sometimes the only, viable manufacturing method.

- If your primary focus is producing complex, precise metal parts in high volume: Traditional press-and-sinter tooling offers exceptional repeatability while minimizing waste and secondary machining.

- If your primary focus is creating one-off prototypes or highly customized geometries: A sintering-based additive manufacturing process like DMLS provides unparalleled design freedom.

Ultimately, understanding the principles of sintering empowers you to design and manufacture parts that are stronger, more complex, and made from a wider range of materials.

Summary Table:

| Stage | Key Action | Outcome |

|---|---|---|

| 1. Preparation | Mixing metal/ceramic powders | Uniform powder blend ready for forming |

| 2. Compaction | Pressing powder in a mold | "Green compact" in the desired shape |

| 3. Heating | Heating below melting point | Particles fuse, increasing density and strength |

| 4. Cooling | Controlled cooling in a furnace | Solid, strong part with final properties |

Ready to leverage sintering for your lab's projects?

Whether you are developing new materials with high melting points, creating complex prototypes, or optimizing high-volume production, the right equipment is critical. KINTEK specializes in high-quality lab furnaces and consumables essential for precise sintering processes.

Contact our experts today to discuss how our solutions can help you achieve superior results in material strength, geometric complexity, and production efficiency.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- Primary Function of Vacuum System in Hot Press Furnaces? Optimize Co-50Cr Alloy Sintering & Purity

- What are the core advantages of using a vacuum hot pressing furnace for Cu/WC composites? Superior Density & Bonding

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity