At its core, hot pressing is a specialized sintering process where high temperature and immense pressure are applied simultaneously to a powdered material. Unlike traditional methods that separate pressing and heating into distinct steps, hot pressing combines them into a single, unified operation. This forces the powder particles to fuse together into a dense, solid component without ever reaching the material's melting point.

The defining characteristic of hot pressing is its simultaneous application of heat and pressure. This single-step approach is engineered to achieve superior material density and performance by minimizing porosity, but it trades the speed and scalability of other methods for this exceptional quality.

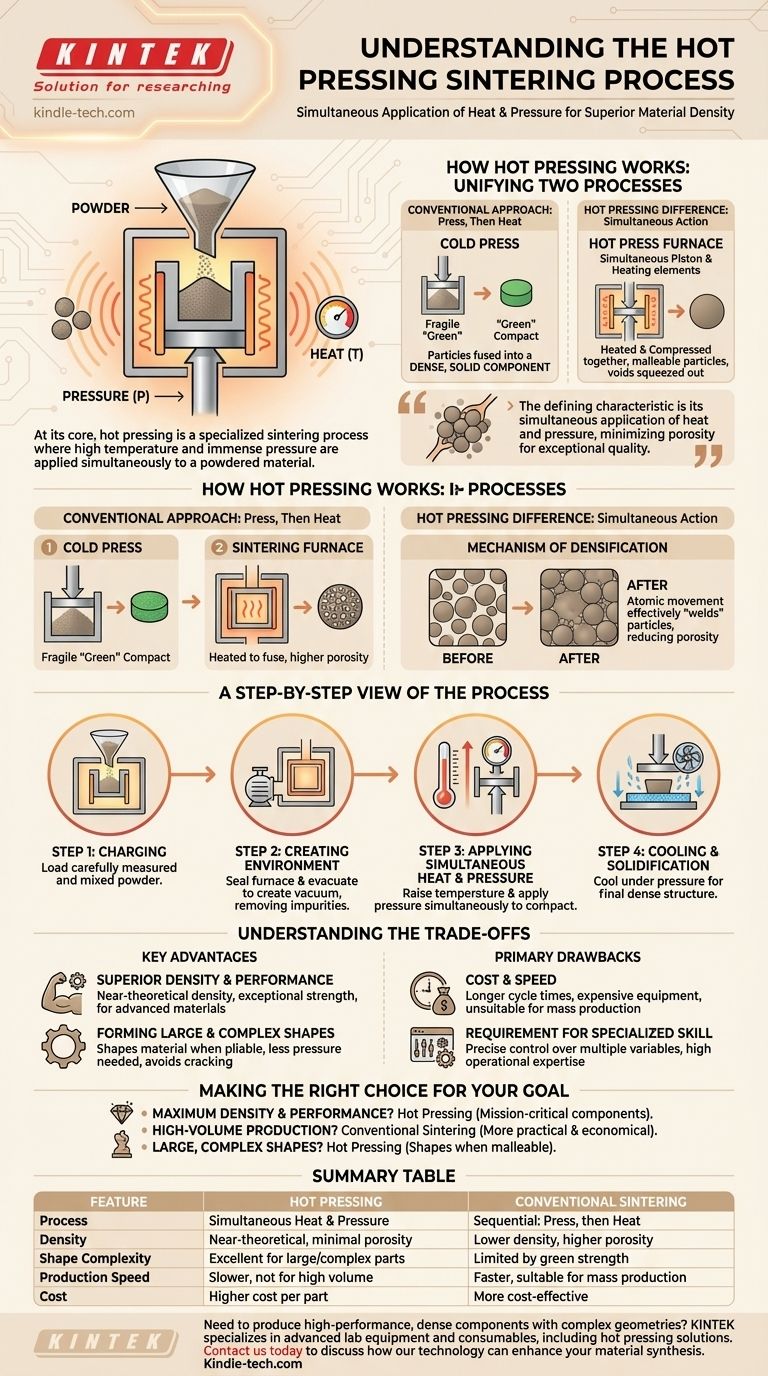

How Hot Pressing Works: Unifying Two Processes

To understand hot pressing, it's useful to contrast it with more conventional sintering methods where the steps are sequential.

The Conventional Approach: Press, Then Heat

In many standard sintering operations, a powder is first compressed into a desired shape at room temperature, a step often called "cold pressing." This creates a fragile "green" compact. Only then is this pre-formed part placed in a furnace and heated to fuse the particles together.

The Hot Pressing Difference: A Simultaneous Action

Hot pressing eliminates this separation. The raw powder is placed directly into a mold, typically made of graphite, which is then heated while mechanical pressure is actively applied.

By heating the material as it's being compressed, the particles become more plastic and malleable. This allows them to deform and bond more effectively, squeezing out the voids between them with greater efficiency.

The Mechanism of Densification

At a microscopic level, the combination of heat and pressure accelerates the diffusion of atoms across the boundaries of individual powder particles. This atomic movement effectively "welds" the particles together, reducing the empty space (porosity) and creating a highly dense, unified solid mass.

A Step-by-Step View of the Process

A typical vacuum hot pressing cycle provides a clear illustration of the key stages involved in this advanced manufacturing technique.

Step 1: Charging

The process begins by loading the carefully measured and mixed powder into the mold or die within the hot press furnace.

Step 2: Creating the Environment

The furnace is sealed and evacuated to create a vacuum. This critical step removes gases and potential impurities that could interfere with the bonding process or lead to defects in the final product.

Step 3: Applying Simultaneous Heat and Pressure

The furnace temperature is raised to the target sintering temperature, which is below the material's melting point. Simultaneously, a specific amount of pressure is applied through a ram or plunger, compacting the now-heated powder.

Step 4: Cooling and Solidification

After holding the material at the set temperature and pressure for a predetermined time, the system is carefully cooled. The pressure is typically maintained during the initial cooling phase to ensure the part solidifies into its final, dense structure.

Understanding the Trade-offs

Hot pressing is a powerful but highly specialized tool. Its selection depends entirely on balancing its unique advantages against its inherent limitations.

Key Advantage: Superior Density and Performance

The primary benefit of hot pressing is the ability to produce parts with near-theoretical density. By eliminating porosity so effectively, the process yields components with exceptional mechanical strength, hardness, and overall performance, particularly for advanced materials like technical ceramics and cemented carbides.

Key Advantage: Forming Large and Complex Shapes

Because the material is shaped while it is hot and more pliable, less pressure is often required compared to cold pressing. This allows for the creation of very large parts or components with complex geometries that would be prone to cracking or deformation using other methods.

The Primary Drawback: Cost and Speed

Hot pressing is not a high-volume production method. The cycle times are significantly longer, the equipment is more expensive, and the process is more energy-intensive. This results in a higher cost per part, making it unsuitable for mass production.

The Requirement for Specialized Skill

The process requires precise control over multiple variables simultaneously—temperature, pressure, vacuum levels, and timing. This demands high operational expertise and sophisticated process control to achieve repeatable, high-quality results.

Making the Right Choice for Your Goal

Selecting hot pressing requires a clear understanding of your project's non-negotiable requirements.

- If your primary focus is maximum material density and performance: Hot pressing is often the superior choice, especially for mission-critical components made from advanced materials.

- If your primary focus is high-volume production and cost efficiency: A conventional multi-step process involving cold pressing followed by furnace sintering is almost always the more practical and economical solution.

- If your primary focus is producing large, non-deformed, or geometrically complex parts: Hot pressing provides a distinct advantage by shaping the material when it is most malleable and resistant to fracture.

Ultimately, hot pressing is a high-precision manufacturing tool reserved for applications where the final material quality cannot be compromised.

Summary Table:

| Feature | Hot Pressing | Conventional Sintering |

|---|---|---|

| Process | Simultaneous heat and pressure | Sequential: press, then heat |

| Density | Near-theoretical, minimal porosity | Lower density, higher porosity |

| Shape Complexity | Excellent for large/complex parts | Limited by green strength |

| Production Speed | Slower, not for high volume | Faster, suitable for mass production |

| Cost | Higher cost per part | More cost-effective |

Need to produce high-performance, dense components with complex geometries?

KINTEK specializes in advanced lab equipment and consumables, including hot pressing solutions designed for demanding laboratory and research applications. Our expertise ensures you achieve superior material density and precise shapes for your most critical projects.

Contact us today to discuss how our hot pressing technology can enhance your material synthesis and meet your specific laboratory needs.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How does a vacuum hot press furnace address structural defects in as-cast CoCrPtB alloy ingots? Optimize Your Density

- What performance improvements does Ga-LLZO exhibit after HIP treatment? Double Your Ionic Conductivity

- What is the voltage of spark plasma sintering? Unlocking Fast, Low-Temperature Densification

- Why is a vacuum hot pressing furnace required for bulk amorphous Ni-Zr-Ti-Si alloys? Ensure High-Purity Densification

- What are the advantages of using Vacuum Hot Pressing Sintering Furnaces? Superior Microstructure in HEA Production

- Why is an argon protective atmosphere preferred over a high vacuum environment when using a hot press furnace?

- What is the densification mechanism of hot isostatic pressing? Achieve Perfect Material Density

- What processing conditions does a vacuum hot press furnace provide? Optimize GNPs-Cu/Ti6Al4V Fabrication