To answer the question "What is the smallest injection mold machine?", we need to focus on the information provided about specific machines and their characteristics.

The references mention various types of molding and pressing equipment, but the most relevant information is about the Babyplast 10/12.

The Babyplast 10/12 is explicitly described as one of the smallest, fully hydraulic, injection molding machines.

Summary: The Babyplast 10/12 is identified as one of the smallest fully hydraulic injection molding machines.

This machine is suitable for tasks requiring precision and small-scale production, such as molding polymer films or pressing materials at lower tonnages.

Its features include easy mold changing, quiet operation, high stability, and precision.

The Babyplast 10/12 is part of a range of custom machines and production line services offered by specialized manufacturers, ensuring high quality and compliance with international standards like CE, ISO, SGS, and BV.

5 Key Points Explained: What Makes the Babyplast 10/12 Stand Out

1. Identification of the Smallest Injection Mold Machine

The Babyplast 10/12 is explicitly mentioned as one of the smallest fully hydraulic injection molding machines.

This designation is crucial as it directly answers the question about the smallest machine.

2. Features and Capabilities

Precision and Small-Scale Production: The Babyplast 10/12 is suitable for tasks requiring high precision, such as molding polymer films or pressing materials at lower tonnages (4 tonnes or less).

This makes it ideal for applications where small quantities and detailed work are necessary.

Operational Characteristics: The machine is noted for its quiet operation, high stability, and precision, which are beneficial for both the quality of the end product and the working environment.

3. Customization and Quality Assurance

Custom Machine Options: The manufacturer offers a range of custom machines, molds, robot arms, auto feeders, and full production line services.

This indicates a commitment to providing tailored solutions that meet specific industrial needs.

Quality Control: The machines are manufactured with high-quality components and have passed stringent international certifications (CE, ISO, SGS, BV), ensuring reliability and safety.

4. Technical Specifications

Construction and Design: The machine body uses a bending structure for strength, and oil pipes are designed with a Clip-on structure to prevent leaks.

These features enhance the durability and efficiency of the machine.

Adjustability: Parameters such as pressure, stroke, and pressurizing time are adjustable, allowing for flexibility in processing requirements.

5. Applicability and Scope

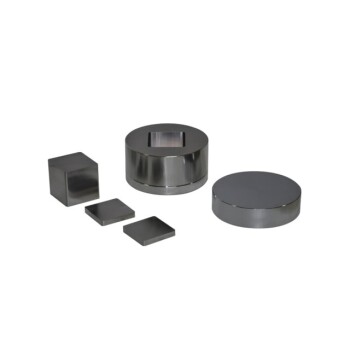

Wide Range of Applications: The Babyplast 10/12 is suitable for various applications including metal products, electrical appliances, jewelry, locks, and powder metallurgy.

This versatility makes it a valuable tool in multiple industries.

By focusing on these key points, the answer provides a comprehensive understanding of the Babyplast 10/12 as the smallest injection mold machine, detailing its features, capabilities, and the benefits it offers to potential users.

Continue Exploring, Consult Our Experts

Elevate your precision molding game with the Babyplast 10/12, the smallest, fully hydraulic injection mold machine that excels in both quiet operation and unparalleled precision.

Customizable for your unique needs and boasting international quality certifications, it’s the smart choice for small-scale production and delicate tasks.

Don’t settle for less—take your manufacturing to the next level.

Contact KINTEK SOLUTION today and discover how our tailored solutions can transform your workshop!