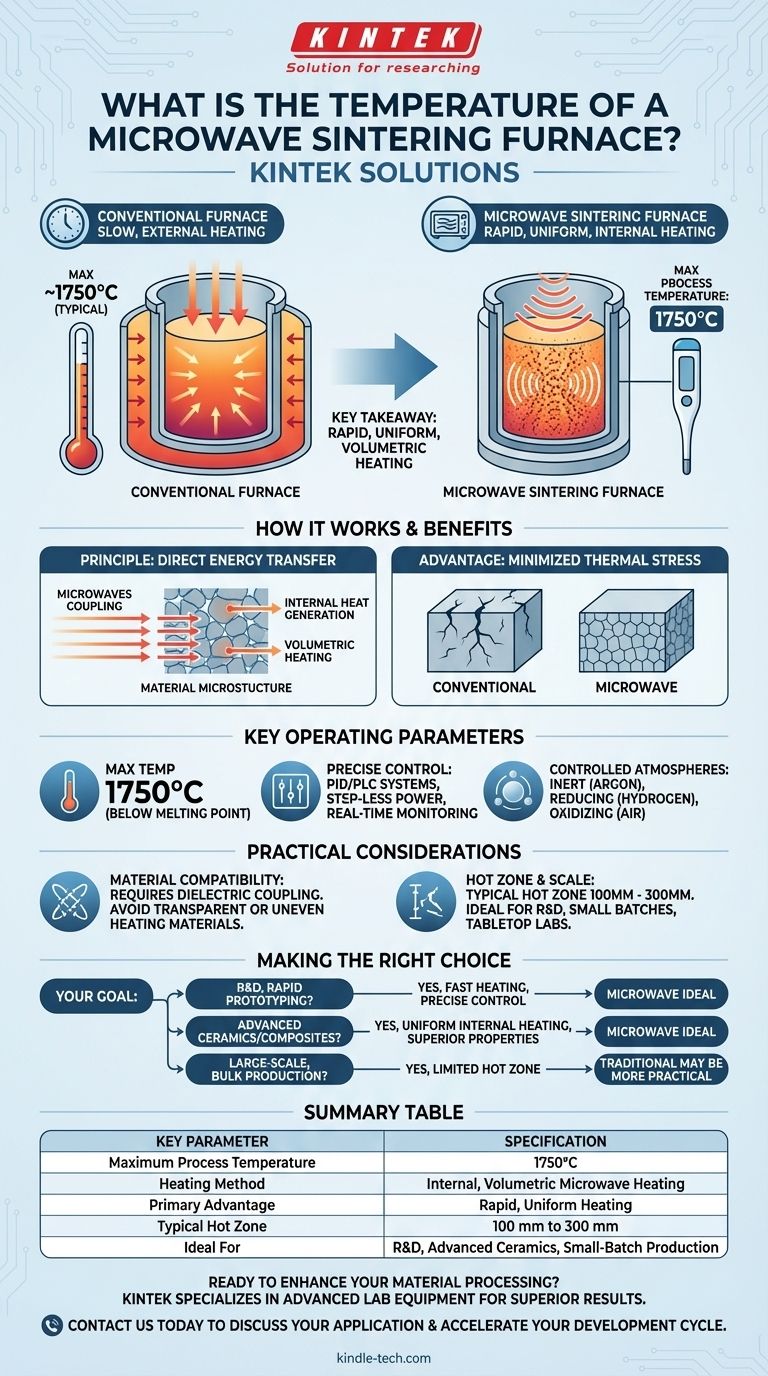

To be direct, a high-temperature microwave sintering furnace can achieve a maximum process temperature of 1750°C. This temperature is reached and controlled using microwave energy, which directly heats the material internally rather than heating it from the outside in, as a conventional furnace does. The entire process is carefully managed to remain below the material's melting point.

The critical takeaway is not just the specific temperature, but how it is achieved. Microwave sintering provides rapid, uniform, internal heating, which offers distinct advantages for processing advanced materials compared to traditional methods that rely on external heat sources.

How Microwave Sintering Works

The Principle of Direct Energy Transfer

A conventional furnace heats the air or elements around a material, slowly conducting heat from the surface inward. This can create thermal gradients and take a significant amount of time.

Microwave sintering is fundamentally different. It uses an electromagnetic field to generate heat inside the material itself.

The Role of Microstructure Coupling

The process works because the microwave energy couples directly with the microstructure of the material, causing its particles to vibrate and generate intense, uniform heat. This is often referred to as volumetric heating.

This internal heat generation allows the material to reach the target sintering temperature much more quickly and evenly than with conventional methods.

Key Operating Parameters and Features

Maximum Process Temperature

The upper limit for these systems is typically 1750°C. However, the goal of sintering is to fuse particles together without melting them, so the actual operating temperature is always set below the material's specific melting point.

Precise Power and Temperature Control

Modern microwave furnaces offer extremely precise control over the sintering cycle. They use step-less power control managed by sophisticated systems like high-end PID controllers or industrial PLCs with touch screen interfaces.

Temperature is monitored in real-time using non-contact sensors, ensuring the process remains within tight specifications.

Controlled Sintering Atmospheres

A crucial feature for processing advanced materials is the ability to control the furnace atmosphere. These systems can operate with inert (e.g., argon), reducing (e.g., hydrogen), or oxidizing (e.g., air) atmospheres to prevent unwanted chemical reactions.

Understanding the Practical Considerations

Material Compatibility is Key

The single most important limitation is that the material must be able to effectively couple with microwave energy. Some materials are transparent to microwaves and will not heat up, while others may heat unevenly, creating "hot spots."

Successful implementation depends on understanding the dielectric properties of the material being sintered.

Hot Zone and Production Scale

Microwave sintering furnaces typically have a defined and limited effective hot zone, often ranging from 100 mm to 300 mm. This makes them exceptionally well-suited for research, development, and the production of smaller, high-value components.

Tabletop versions are also available, specifically designed for small-scale lab experiments to establish preliminary results before scaling up.

Making the Right Choice for Your Goal

The decision to use microwave sintering depends entirely on your material, production scale, and desired outcome.

- If your primary focus is research and rapid prototyping: This technology is ideal due to its fast heating cycles and precise control over small batches.

- If your primary focus is sintering advanced ceramics or composites: The uniform, internal heating minimizes thermal stress and can produce superior material properties compared to conventional methods.

- If your primary focus is large-scale, bulk material processing: The limited hot zone size may make traditional furnaces a more practical and cost-effective solution for very large parts or high-volume manufacturing.

Ultimately, microwave sintering offers unparalleled speed and precision for the right applications.

Summary Table:

| Key Parameter | Specification |

|---|---|

| Maximum Process Temperature | 1750°C |

| Heating Method | Internal, Volumetric Microwave Heating |

| Primary Advantage | Rapid, Uniform Heating |

| Typical Hot Zone | 100 mm to 300 mm |

| Ideal For | R&D, Advanced Ceramics, Small-Batch Production |

Ready to enhance your material processing with the speed and precision of microwave sintering?

KINTEK specializes in advanced lab equipment, including microwave sintering furnaces, to help you achieve superior results in research and small-batch production. Our systems offer precise temperature control up to 1750°C and uniform volumetric heating, ensuring high-quality outcomes for advanced ceramics and composites.

Contact us today to discuss your specific application and discover how KINTEK's solutions can accelerate your development cycle and improve your material properties.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the sintering temperature of zirconium? A Guide to the 1400°C-1600°C Range for Dental Labs

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia